The glue is used for suture, spot application when connecting plumbing elements, installing carpet, linoleum, and other building materials. Cold welding glue joins homogeneous surfaces, and also creates a permanent connection of metal with plastic, ceramics, plastic or concrete with tiles, steel, glass. The composition is used to repair pipes, cars, it is used in a home workshop.

What is cold welding

The properties of the glue, its technical characteristics, setting time and application features depend on the constituent components.

When choosing, factors are taken into account:

- working temperature at the junction to maintain performance;

- maximum efforts in the seam being joined;

- setting speed, consistency;

- release form;

- the type of materials.

Material characteristics:

- the shear strength of the seam is not less than 990 N under the action of a force of 2.2 MPa;

- separation stress is at the level of 49 - 5.8 MPa;

- shear test shows 190 - 237 N;

- the initial setting time is 40 - 60 minutes;

- full set of strength will require 24 hours.

The composition retains its plasticity for 8 - 10 minutes, so it is possible to correct the position of the element.

Composition and properties

Pure epoxy resin is fragile, destroyed by vibrations, so they add to it plasticizer. The filler increases heat resistance, heat conductivity. In this capacity, metal powder of cast iron, steel, aluminum acts. Artificial and mineral particles are also introduced.

Main components epoxy cold welding:

- epoxy resin is the base, connects the rest of the ingredients;

- filler;

- additives that determine the properties and scope of use;

- the hardener (amine type or polyethylene polyamine) reacts with the resin.

Adhesive for cold welding differs from other compositions in that it has a radically different effect and properties. The strength of the hardened layer does not change if it has a large thickness... The composition can be used to fill the missing layer, to close the chipped groove on the countertop, furniture surface.

After filling the volumetric chip and hardening, the surface is polished, covered with a suitable paint and varnish material. The glue as a modeling paste is not visible under a thin film.

Applications

Glue Application Cases:

- metal parts are glued not only in a familiar environment, but also in a liquid or under voltage;

- good adhesion is observed with plastic and plastic parts (with the exception of polyethylene);

- dock glass and ceramic tiles with concrete, plaster during repair work;

- glue plots linoleum and carpetif you change a small area.

Plumbers use cold welding method to eliminate leaks batteries, sewer and water pipes. The composition works well for installing cisterns, connecting washing machines, sinks, bathtubs and showers (pipe connections). The owner of the premises independently solves the problem of restoration without the involvement of specialists.

Glue is also used in car repairs. The composition will help to close up small cracks in the gas tank, repair the manifold, and glue the separated joint.

Varieties of material

There are several types:

- for point joining in cases of meticulous repairs;

- suture joint used in the creation of cases in industry;

- butt bonding for wires;

- shear mount used for plumbing wiring, pipe repair.

Two-component mixtures sold in two containers or tubes containing the hardener and resin. They are mixed before work, squeezing out the same volume of each of the components.

One-component mixtures the consistency is similar to office glue (liquid glass). Compositions are referred to as universal types. Materials are glued in different combinations. They are sold in small portions in the form of tubes. Such glue quickly hardens after opening the container, so it is used as much as possible, purchased in the right amount.

By composition

They use such material types:

- repair for the restoration of machine parts of mechanisms (exhaust pipes, exhaust manifolds, etc.):

- waterproof mixtures that work perfectly in conditions of high humidity and in direct contact with water (showers, swimming pools, water pipes);

- heat resistant do not lose strength when structural parts are heated more than + 1000 ° C (connections in electromechanics, electrical engineering);

- universal adhesives are designed for different jobs, they are distinguished by high-quality adhesion to different surfaces.

The manufacturer indicates the parameters on the packaging, there is also information about the composition and recommendations for use. Resistance to high temperatures, the water resistance of the composition will remain if the application technology is followed.

By appointment

In addition to compositions for universal use, there are special types for working with specific materials. Compositions designed for many combinations show low strength.

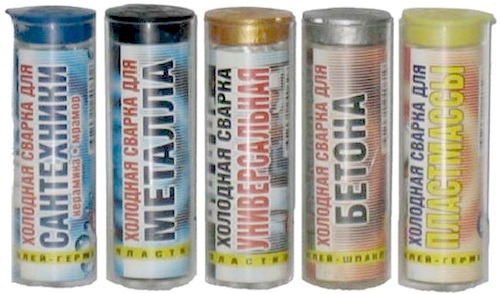

Each manufacturer produces in a line compounds for connection:

- metals;

- plastic;

- rubber;

- concrete;

- glass.

Compositions for welding steel surfaces include small metal particles to allow the connection of similar parts.Do not use adhesives designed for other materials, as the result will not be achieved.

Mixture for plastic used to repair pipes, instrument cases. Despite the alternative use of the glue gun, the ready-made, cold-welded tubes allow for a tight and durable connection.

Cold glue for rubber connects hard and soft material, such compounds are used in the repair of linoleum in the case of repair work. The quality of adhesion with this compound is much higher than with double-sided tape or other types of glue.

Compositions for concrete are distinguished by a high degree of adhesion. Hygroscopic and dusty concrete requires a special approach. Cold welding glue is used if you want to attach decorative elements to concrete without drilling with punches or impact drills. The composition is also used to restore destroyed monuments.

How to work with cold welding

Application rules:

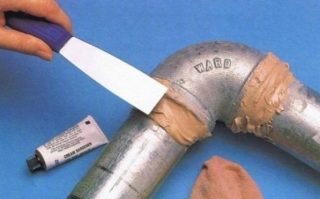

- surfaces are cleaned with emery, then degreased with acetone, dried;

- smooth surfaces are sanded with emery;

- moisten the palms to reduce adhesion of the mass;

- two-component are mixed, the rod is kneaded in the hands;

- apply quickly, parts are clamped with clamps, or pressed with a load;

- the excess is removed with a wet sponge.

Adhesive manufacturers recommend mixing and application times. Indicate the time of hardening and the beginning of grinding.