Styrofoam used to be glued to walls using a dry compound, which was diluted with water before use. Mounting foam adhesive for insulation is much more convenient to work with. If we calculate the economic components (consumption, cost), it turns out that the use of foam is a little more expensive. Despite this fact, professionals choose the composition in spray cans, since labor productivity is accelerated twice.

Material description

Material features:

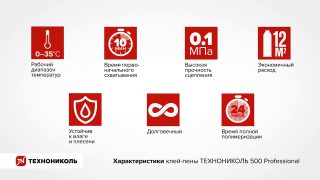

- Freezes quickly. After 30 minutes, excess foam is easily removed with a knife, and after two hours, sheathing or putty is made using expanded polystyrene. The plates will not move as they are firmly fixed to the base.

- Compact packaging. In cylinders, the substance is pushed out under pressure using a pistol. It is forbidden to put containers near an open fire.

- Health safety during installation and during operation.

- Durability and no deformation. Over time, when working conditions change, the foam glue will not collapse or crack.

The release form assumes simple use. Anyone can apply foam glue by reading the instructions. A good product is never liquid, so there are testers in the store to check. There are types of glue that you can work with in cold weather, they write about this on the package.

Properties

Specifications material:

- adhesion to concrete, expanded polystyrene 0.3 and 0.1 MPa, respectively;

- different types are allowed to be used at temperatures from -10 ° to + 40 ° C;

- thermal conductivity coefficient 0.04 W / mK;

- fire safety;

- there are no freons in the composition, which are hazardous to health;

- the primary expansion is minimal.

- when using a 400 ml balloon, the consumption is calculated per 4 squares of the surface, denser formulations are consumed more;

- from a can with a capacity of 750 ml pasted over with foam plastic 12 m² of the plane.

Material consumption depends on the mass of the binder in the composition. In a large bottle it contains 260 g, the yield is 85%. Consumption does not depend on the capacity of the cylinder.

Applications

Foam glue is used in cases:

- fixing the material in a horizontal and vertical way;

- installation of press-free polystyrene on the facade of buildings;

- installations of extruded polystyrene foam with a groove-ridge lock on the surface of the foundation;

- finishing with insulation of the basement and pedestal of the house;

- insulation of foundations protruding above the ground;

- insulation from the cold of temporary barracks, trailers, electrically heated pavilions;

- protection of walls of garages, sheds, storages, cellars.

Polyurethane foam adhesive adheres well to smooth, porous and corrugated surfaces. The material adheres to concrete, brick, plaster, wood, metal and plastic. The insulation does not slip after fixing, it is securely attached to the structure. Foam plates on glue from a spray can are attached when installed on the floor, roof, overlap. The retainer works well in the basement, attic, greenhouse.

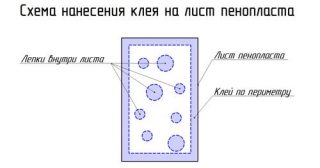

Before starting work, the cylinder is placed on a flat base, the cap is removed, and the valve is installed in the pistol landing niche. The first layer of foam is applied after brief shaking. Apply 3 - 4 strips of foam to the reverse side of the panel, wait a few minutes for the mass to expand. The plate is pressed against the plane with the processed side.

Varieties of foam glue

Any species include isocyanate oligomers. Substances under the influence of ambient oxygen displace isobutane and propane. Foam adhesives are produced in metal cylinders, the capacity of which is 400, 750, 1000 ml.

Types of glue:

- universal;

- polyurethane for expanded polystyrene, for XPS boards;

- for PIR and PUR panels.

Universal the composition is produced as one-component for internal and external use. Not only insulation is placed on it, but also decorative interior elements made of wood, tin, plastic. It resists moisture well, aging, adheres well to materials. Blue foam glue.

Polyurethane glue is used for mounting extruded and extruded polystyrene foam. This glue foam is also used for fixing lining, PVC strips, g / cardboard, ceramics.

Foam adhesive for PIR and PUR panels after solidification becomes gray. The setting time is increased compared to the universal material.

Manufacturers rating

The best adhesive mixtures are produced by France and Germany. The second place is shared by Turkish, Polish and Estonian brands. Domestic manufacturers also produce decent products. Chinese adhesives are not worth buying, since the products are toxic, sometimes of poor quality.

The rating includes three main brands:

- TechnoNIKOL;

- Macroflex;

- Ceresit.

TechnoNIKOL has several enterprises in Italy, Russia, Germany, Lithuania, Belarus. The work is guided by a scientific approach combined with experience.

Company Macroflex is part of the industrial association Henkel. One-component adhesive foams are in demand in the markets of more than 70 countries; production facilities are located in 30 countries. Manufacturers work on the principle of product efficiency, integrity in relation to customers.

Ceresit is also a subsidiary of the German large company Henkel. The assortment includes a large release of goods, among which glue-foam takes its rightful place.