Aerated concrete blocks cannot be fastened together with a cement-sand mortar. For masonry walls and partitions, special purchased compounds or glue-foam for aerated concrete are used. The choice depends on the climatic conditions during construction, the quality of the products and the reputation of the manufacturer. It is important to familiarize yourself with the technology of work in advance and correctly calculate the amount of material.

Material features

Adhesive for gas silicate blocks features positive consumer properties:

- plasticity allows you to accurately install masonry parts by adjusting the thickness of the seams;

- low consumption due to the small thickness of the seams;

- excellent adhesion;

- no shrinkage after drying;

- resistance to mold and mildew;

- the minimum dimensions of the cold bridges and the tightness of the seams;

- special types of glue can be used at low temperatures, which allows you not to stop construction in the winter;

- fast solidification - several rows of blocks can be installed during the day;

- financial savings due to low foam consumption;

- the composition is completely ready for use, it is important only if necessary to heat the cylinder to the temperature recommended by the manufacturer;

- one standard 700 ml cylinder replaces an approximately 25 kg bag of dry mix - this eliminates the hassle of transporting material to the workplace.

Adhesive for aerated concrete blocks in spray cans has a significant drawback: with different geometric dimensions of gas silicate, it will not work to level the masonry with foam for aerated concrete.

Adhesive for aerated concrete is not used for the construction of load-bearing walls in houses above one floor, unless otherwise indicated in the product passport.

The main reason for the reluctant use of foam by builders is distrust of the material and doubts about the strength of the masonry after several years of operation. The material is relatively new, so until it is impossible to "feel" the walls of old houses, there will be distrust.

Composition, characteristics and scope

Externally, aerated concrete glue is very similar to polyurethane foam. Both materials are based on polyurethane, but they add additives:

- improving adhesion to mineral substrates;

- reducing the expansion coefficient;

- accelerating the time of hardening and full set of strength;

- antiseptics and fungicides.

Specifications

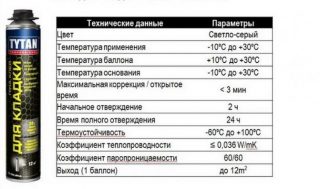

Foams from different manufacturers may vary slightly, but average characteristics will be approximately the same:

- working temperature from +10 to + 30 ° С for summer glue and not less than minus 10 degrees for frost-resistant version;

- the optimum temperature for use is about 20 ° C;

- The "life time" of the foam before the block is laid is about 2 minutes;

- allowable position correction time - 3-4 minutes;

- setting time before installing the next row is about 2 hours;

- full strength gain period - 24 hours;

- compressive strength - 7 Atm., bending strength 2.5 Atm .;

- use temperature range minus 60 - 100 ° С;

- fire resistance class - highly flammable.

The exact characteristics are indicated on the packaging of the goods, they should be taken into account when purchasing.

Release form

With a large volume of masonry, they acquire special pistolallowing you to work comfortably in hard-to-reach places and not get your hands dirty. As a rule, foam for professionals is packaged in larger tubes, which ultimately affects the cost of masonry.

For convenience and to eliminate confusion, manufacturers add dye to formulations suitable for use in winter. Such mixtures are called "gray". Winter glue is versatile and can be used at any time of the year. White glue loses its properties at temperatures below 10 ° C.

Consumption calculation

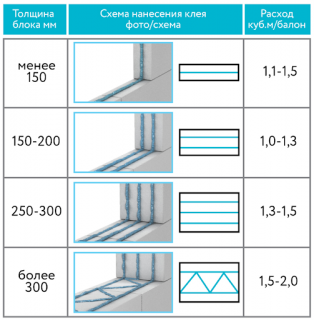

Some manufacturers indicate on the packaging, how many meters of strip can be obtained from one cylinderas a rule, this is done by the largest manufacturers. If there is no such data, taking into account the blowing of the gun and possible blemishes during application, they acquire glue for the gas block at the rate of 1 cylinder of 750 ml per 1 cube of blocks.

When erecting partitions from a block with a thickness of 100 mm (1 strip of glue), it is approximately assumed that the packaging will be enough for 10 m² of the wall. You can find out the consumption of glue for 1 m³ of aerated concrete blocks using online calculators that are available on the websites of manufacturers or construction companies.

Which glue to choose

When choosing foam for aerated concrete, pay attention to several parameters.

Consumption adhesive composition for one cubic meter or 10 m². The parameter is specified by the manufacturer or calculated by the builders themselves. Liquid glue allows you to stack more blocks, but this consistency is not strong in masonry. Working with a thick composition will require great skill, so inexperienced builders are better off refusing to buy. You can evaluate the consistency in large building markets, where they give you the opportunity to use a "sampler".

Period solidification is important for professional bricklayers. If the glue dries for a long time, the time before the start of laying the second row of blocks will increase. This slows down construction on small sites.

Allowed correction time important to know for novice builders. The bigger it is, the better. Experienced craftsmen install blocks quickly, so this indicator is rarely paid attention to.

Full hardening period important on small objects, when they build 1 partition, it is necessary to lay 3-4 rows of blocks only after complete setting.

Temperature during laying affects the choice of glue, frost-resistant options are more expensive than usual.

Operating temperature range operation of the building. The parameter of most adhesives is suitable for any operating conditions, but when buying, they pay attention to the characteristic if the foam is used to build external walls.

Popular brands

In hardware stores, up to a dozen varieties of foam glue are sometimes presented. They differ in price and quality.

Low price it happens with products with a small yield of the mixture, so it will not be possible to achieve savings.You can choose a cheap option only in the event of a sale or any promotions from the seller.

Reviews show that the best properties are possessed by products of Finnish and German manufacturers, and you should not buy Chinese samples. It makes sense to pay attention to reviews on the network about a particular model, they can be found on forums and reviews.

Popular manufacturers from Russia: "Technonikol", "KUDO PROFF", "MARCON Masterblock".Reliable brands are: Ceresit, Knauf, Akfix.

Before buying, you should inquire about the assortment presented in local retail outlets, read the characteristics on the manufacturer's website.

Terms of use

Before starting laying, it is important to familiarize yourself with the manufacturer's recommendations and safety measures during work.

Safety regulations:

- be sure to use protective equipment - gloves, hats (when laying the upper blocks), respirators in closed rooms;

- do not use foam near open fire and do not store cylinders near heating devices;

- heat the foam to the required temperature only in a warm room, do not use open fire and electric stoves;

- immediately wash off the foam that has got on the skin or clothes with special solutions, otherwise after drying it will be impossible to do this.

Operating procedure

The algorithm for laying gas silicate and foam block is simple, but it requires strict adherence to the sequence and technology of work.

Before starting work, the glue foam is kept indoors for about a day.where the installation will be carried out so that the cylinder is warmed up to the operating temperature.

First row blocks are laid on adhesive mixtures for foam blocks in order to perfectly level the horizontal surface. Before installing the unit thoroughly clean the contacting surfaces - fragments and debris interfere with accurate joining of products, which reduces the strength of the masonry.

Before installing in the gun, heated cylinder shake vigorously for about 60 seconds... Close the gun feed valve completely. The protective cap is removed from the balloon. When screwing the container into the gun you cannot use excessive physical force, the threads of the adapter and the bottle must match. By adjusting the valve, they achieve the required foam output in terms of volume - a polyethylene bag is used for waste, which is subsequently disposed of.

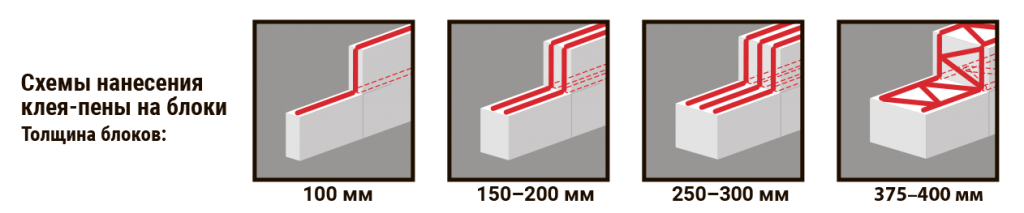

By adjusting, the foam is released in a strip of about 2 cm in diameter, this is the optimal amount for masonry.

On a thin block apply one line of glue in the middle of the surface. For blocks from 150 mm the line of glue should be 30–40 mm away from the edge. On wide blocks two lines are applied along the edges, and the space between them is filled in a zigzag pattern.

Immediately after applying the glue install the unit, observing the installation timespecified by the manufacturer. The adjustment must also be made as soon as possible. If an error is found and the time is not observed, the installation is repeated, carefully removing the remnants of the set mixture. Use a rubber mallet to correct the position.

When the blocks are joined, the foam is applied to the vertical and horizontal surfaces.

Full polymerization occurs within a day, after which the beads of glue that protrude from the seams are cut off with a sharp knife.

The cylinders are changed as needed.