In private construction, a situation often arises when a strong durable material is used for the construction of walls, corresponding to the climatic conditions of the region, but not aesthetically pleasing. Such a building needs cladding, which will give it a presentable look and additionally protect it from rain, sun and snow. Clinker brick is a suitable option for this.

Material features

The characteristics of the stone are due to the peculiarities of production. To make it take special refractory clays... Blank after forming fired in a furnace at a temperature of 1200-1300 ° С, so that in terms of resistance to temperature, it is not much inferior to fireclay. However, this technology is used for a different reason.

The material thus obtained does not contain pores, and any kind. Water does not get inside the stone to a great depth, and when it freezes, it does not destroy it.

Clinker is much more often used for cladding rather than construction, since, due to the production technology used, it is much more expensive than other materials.

Application, advantages and disadvantages

Ceramic clinker bricks are taken for the construction of houses, calculated for long-term operation... The service life of which building is not limited. They prefer this material when they want to get rid of the need to care for, repair or somehow decorate the house. The clinker provides both the quality of the walls, and a decent appearance.

If such a construction is "not affordable", the house is finished with ceramic bricks. The same method is used if it is better to build the internal walls of the building from a material with heat-retaining properties, like gas silicate.

More about the benefits:

- Brand facing brick reaches M300... Moreover, the material is equally resistant to bearing loads, bending loads, compression.

- Water absorption - 3-4%... The clinker is completely insensitive to rain, snow, cold.

- The standard frost resistance index for facade clinker is 200 full freeze and thaw cycles... The material is used for construction in northern latitudes.

- Ceramics resistant to wear and damage... There is also a bonus: because of the high temperature of annealing, efflorescence, white bloom, "quilts" do not appear on the bricks.

- Private and front clinker differs perfect dimensional and shape accuracy... This makes it easier to lay and makes the joints between the stones thinner. The thinner the seam, the better the wall retains heat.

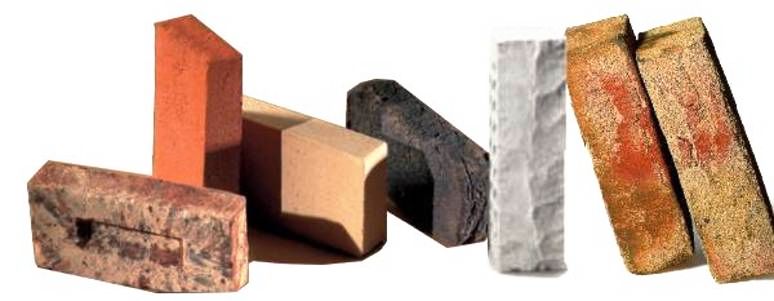

The finishing material is produced in different colors with different textures: smooth, like a palace stone, like an old one, and even a different configuration.

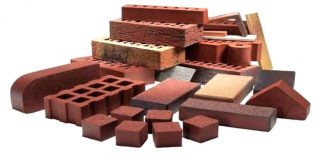

Types of clinker bricks

Clinker bricks are produced for different needs. By purpose, the material is divided into 3 categories.

- Private - used for the construction of supporting structures: walls, columns, plinths, sometimes even a foundation.The stone provides maximum strength with the durability of the structure. The dimensions are in accordance with the standards.

- Facing - or front. Differs in the most accurate sizes and the richest choice of colors. The trough option is often glazed to make the surface resistant to sunlight and rain. Not only shaped bricks are produced - rectangular outlines, but also shaped - triangular, with cut corners, with rounded contours. Shaped stone allows not only revetting walls, but also constructing the most complex architectural details.

- Sidewalk - more like a tile than a brick. The material is resistant to abrasion, although it absorbs moisture more than the facade. Clinker paving stones are extremely durable. This must be taken into account when choosing this material for arranging the yard and garden.

Clinker for special purposes is also distinguished, for example, acid resistant... Such a stone is used for lining chimneys, sheathing of shop walls. It is absolutely acid-resistant.

Ceramic stones are heavy. The clinker cladding of the house must be laid on the project, since a heavy foundation is required. In addition, the thermal conductivity of ceramics is quite high. Solve this problem by issuing 2 types of bricks of different density.

- Corpulent - solid stone without voids. It has maximum load-bearing capacity and maximum mechanical strength.

- Hollow - includes flat, round, rectangular, cone-shaped voids. This has little effect on the mechanical strength, but reduces the weight of the product. Such material retains heat slightly better due to the air-filled cavities. Hollow bricks are ordinary and facing bricks, including shaped ones.

Handmade clay bricks, by definition, do not have the properties of clinker, as they are fired at a low temperature.

Specifications

Clinker bricks have different characteristics in accordance with the purpose. In fact, any kind of it is much superior to silicate or red bricks.

- Density - from 1900 to 2100 kg / m³. Such a high rate is due to the manufacturing process: sintering leads to the almost complete disappearance of the pores. In addition, before firing, the raw material is processed in a press. The device develops a force of up to 5000 kg / m². This means that the stone is able to withstand slightly less load-bearing capacity. Front brick is denser than ordinary brick, and sidewalk brick is denser than front brick.

- Thermal conductivity - this concept indicates the ability to lose heat. It is a value of 1.16 W / m * C for a conventional one, 1.17 W / m * C for a facade one and 1.15 W / m * C for a sidewalk. Hollowness affects the indicator: for a porous stone, the value decreases to 0.22 W / m * C. In the middle and northern latitudes, a clinker house needs insulation.

- Moisture absorption - from 4-6% for an ordinary person to 3-5% for a front one. The stone does not absorb moisture, thereby protecting a wall made of another material from dampness.

- Frost resistance - low porosity also provides resistance to cold. From 100 cycles for ordinary clinker to 300 for paving.

- Vapor permeability - low, since the low porosity does not allow the stone to remove moisture. This is not required from clinker.

- Fire resistance - the material is not flammable, does not support combustion and does not collapse under the influence of temperatures up to + 1800 ° С.

Soundproof and heat-insulating properties are low.

Shapes and sizes

- single - 250 * 120 * 65 mm;

- one and a half - has a width of 88 mm;

- double - with the same width and length, the thickness reaches 140 mm.

They also produce bricks "Euro" - 250 * 85 * 65 mm.

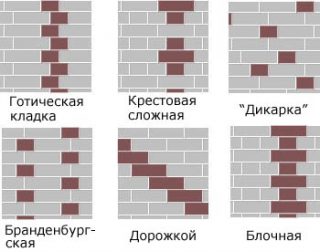

Features of laying clinker bricks

But when laying clinker, you need to do Additional requirements.

- Row first stacks on dryto determine the number and position of the stones. Laying is done taking into account the thickness of the seam. It is 1 cm.

- The optimum thickness can be achieved if the structure is used special mortar for clinker bricks.

- During installation, it is important to observe level height... To do this, vertical slats are placed along the edges of the masonry or in the corner - orders, to which the cords are attached at the level of each row.

- If a ventilated facade is assembled, the masonry provides empty vertical seams... They serve as air outlet holes.

Lay and expansion joints, aligning them with vertical joints for air release. This technique avoids cracking of the stone when the foundation shrinks.