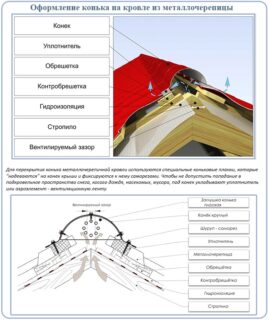

When finishing the roof of a house with roofing metal, the correct installation of additional elements is important. They make up about 5% of the surface area, but they perform important functions: they prevent structural leaks, rotting of rafters, the appearance of mold and mildew in the insulation material. One example of such details is the ridge for metal roofing.

What is a roofing ridge and why is it needed

The ridge strip for metal tiles is a part, the installation of which is carried out along the edge of the intersection of the sloping planes. Its structure is simple: it looks like an ordinary corner. In this case, the shape of the product from the ends can be different - in the form of a semicircle, a triangle or the letter P. At the edges, the metal sheet is bent inward (the size of the bead is about 15 mm on each side) in order to prevent precipitation from flowing under the ridge.

This detail, blocking the gap between the slopes, creates an obstacle not only for water, but also for debris and insects. Its installation ensures cleanliness in the under-roof space. Externally, the design takes on a neat and complete look. The optimum metal thickness of the ridge strip for metal tiles is 1.5-2.5 mm.

Varieties of skates for metal tiles

There are several types of skate geometry:

- The triangular shape is the simplest, the slats have a budget price. They repeat the lines of the corner of the junction of the slopes.

- U-shaped strips have a rectangular geometry at the top. Repeat the shape of the connection of the slopes.

- A semicircular ridge for metal tiles is the most expensive option. From the ends of the structure, plugs of the corresponding shape are mounted (they can also be conical). Having decided to install a round ridge for metal tiles on a roof with complex geometry (for example, hip), you need to purchase a connecting tee in the shape of the letter T or Y.

In addition to the shape, the dimensions of the product are taken into account. The minimum recommended width is 20 cm. It is convenient to install such planks, and you can do without marking. If the width is 15 cm or less, it must be mounted very carefully. In addition, water and dust can more easily get under such a structure, especially if there are often strong winds in the region.

Gaps under the ridge strip

Products have flattened soles designed to be attached to a tile surface. Gaps appear in the joints.

On the positive side, the gap allows air masses to move in the under-roof space, aiding ventilation. Minus - snow and rain water can penetrate into such gaps. As a result, the insulation rots, the wooden elements of the roof are slowly destroyed. To prevent these processes, but not to block the ventilation, a sealing tape is mounted between the product and the tiles. Another option is to install a ridge aero element.

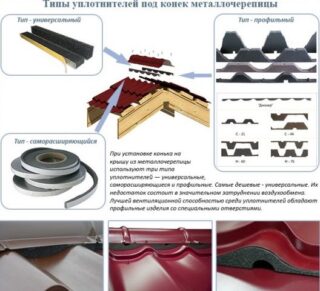

Types and properties of seals

The following types of seals are distinguished:

- Profile - made of polyethylene foam, repeat the lines of a specific tile covering and keep their shape well.They have better air permeability than other species. They are equipped with openings to prevent disturbance of ventilation.

- Soft items are made of polyurethane foam. After laying, they themselves take the desired shape, filling the existing gap. The texture of these seals has cells that allow air to pass through, but retain moisture and debris. Like the previous class, the products can be used for up to 15 years.

- Self-expanding strips are also made from polyurethane foam, but are acrylic impregnated. After installation, they become several times thicker. This process takes 3-5 hours, the product can expand 5 times during this time. On the self-adhesive part, they have a protective strip, which is removed before installation. Products reliably protect from moisture, but do not allow air to pass through. So that ventilation is not disturbed, for every 2 meters of length it is worth leaving a gap of 2 cm.They have the longest service life - 20 years.

The throughput capacity of any type of sealant is not enough to provide full ventilation of the under-roof space. Therefore, their use is recommended to be combined with the installation of point aerators of the "fungus" type. Another option is to install a valve on the ridge.

Ridge aero element for metal roofing

The air permeability of aerial elements is noticeably higher than that of seals, since the mesh has good vapor permeability.

The product is easy to install. The roll unfolds along the ridge, the protective strip is peeled off, the material is pressed against the tiled surface. If a ridge bar is provided in the design, the aero element is fixed on it. For this, a stapler or simple nails are suitable. After that, the side pieces are glued to the tiles. The fixed tape is covered with a skate that masks it well.

Ridge mounting technology

First, the flatness of the ridge axis is checked. If deviations exceed 2 cm, they must be eliminated. The angle of the plank is adjusted to the angle of the connection of the roof slopes. With a large inclination (more than 45 degrees), the product has to be strongly bent. Semicircular products are often deformed from such treatment. Then the supplied end cap is fitted to the new lines or a new plug is made of steel sheet.

They begin to mount the ridge from the end over its bar. At the same time, the edge is released outward by 2-3 cm. Products of a triangular and U-shaped shape are superimposed one on top of the other with an overlap of at least 10 cm. In round versions, joining is performed along the stamping lines. If the roof structure requires it, the ridge of the adjacent slopes are connected by tees. The sealant is installed simultaneously with the installation of the ridge. If it is not self-adhesive, the adhesive must be applied during operation. If an aero element is chosen to seal the gaps, it is mounted even before the installation of the ridge parts. The strips are attached to the tile with self-tapping screws screwed into the ridge.