The general concept of red brick is used in relation to a large assortment of products that differ greatly in composition, appearance and appearance and purpose. When buying, it is important to navigate the features of all types of products.

- Raw materials and production

- Manufacturing process

- Characteristics, scope and technical conditions of production

- Terms and Definitions

- Classification and designation

- Dimensions (edit)

- Symbols

- Technical requirements

- How much does a red brick weigh

- How many bricks are in the pallet

- Packaging, transportation and storage

Raw materials and production

The raw materials for production are low-melting clays and loams... Delivering clay from afar is impractical, so the composition of the main component differs at different factories. An important condition of the raw material should not contain limestone, as this additive reduces the quality of the finished product.

Up to 30% softeners are added to oily clay - quartz sand or loam.

Coal chips, peat or sawdust introduced into the raw material burn out during firing, and voids are formed inside the products, which positively affect the thermal insulation properties, and the mass of the products decreases.

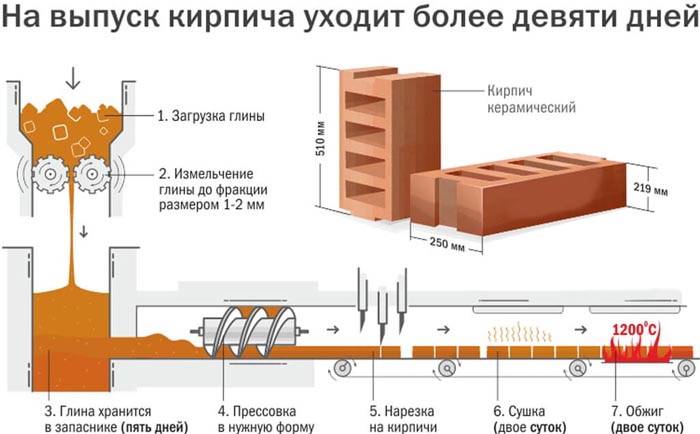

Manufacturing process

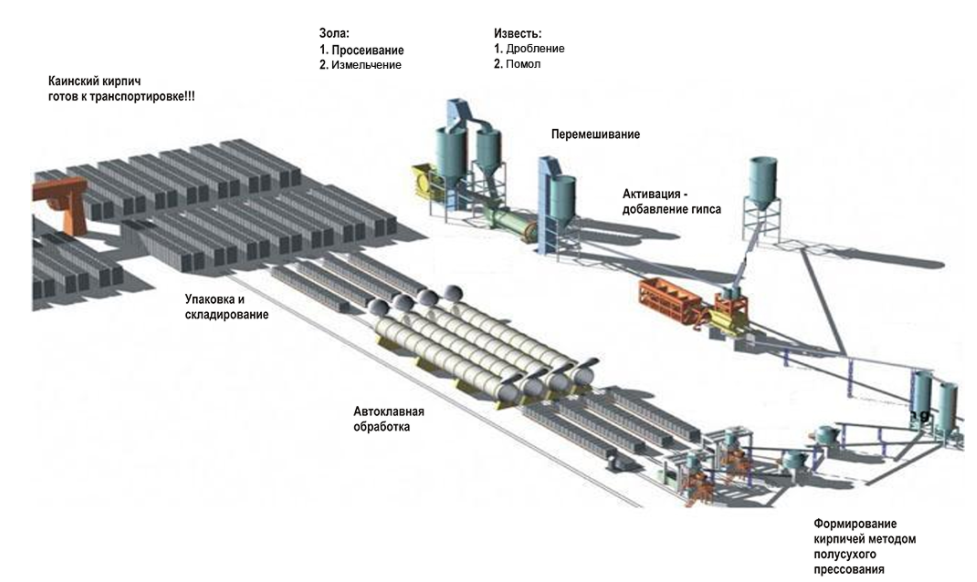

Allocate 2 manufacturing technologies:

- plastic molding;

- semi-dry pressing.

Plastic molding implies processing milled raw materials with wet steam and mixing until a plastic mass is obtained. The clay formed into a tape is cut into piece products - raw. In the future, the "blanks" are subjected to drying until reaching 6–8% humidity. The last stage is burning at a temperature of 900–1000 ° С.

The plastic molding method is used to produce solid, slotted and clinker bricks.

Products stand out low water absorption, as a result of which the durability and frost resistance increase. Full-bodied bricks made using this technology use the foundation and basement masonry.

When semi-dry pressing the clay is dried to a moisture content of 8%, crushed and pressed bricks in forms. Drying is not carried out, but start firing immediately.

Products made by the method of semi-dry pressing must not be used for laying foundations and plinths located below the waterproofing layer.

Semi-dry method is made facing, refractory and ordinary bricks for walls.

Characteristics, scope and technical conditions of production

The general technical conditions that must be fulfilled determine GOST 530, approved in 2012... The requirements apply to bricks and ceramic stones for masonry and cladding of load-bearing, self-supporting and curtain walls, as well as clinker for foundations, plinths and vaults. The requirements of the standard do not apply to refractory, acid-resistant products.

Terms and Definitions

- brick - product used for laying on mortar;

- normal format - standard size of red brick 250x120x65;

- a rock - large-format products with a height of more than 140 mm;

- solid brick, products in which the internal cavities occupy no more than 13% by volume;

- hollow brick - a product with voids in a different order;

- shaped brick has a shape other than a parallelepiped;

- front brick - a product with characteristics that ensure the strength and decorativeness of the masonry .;

- ordinary brick has no decorative processing and serves only for masonry;

The structure of the brick is shown in the figure.

Classification and designation

GOST classifies products according to several parameters:

- Purpose and appearance - privates and facial.

- Presence of deliberately crafted voids - corpulent and hollow. The voids can be parallel to the bed (horizontal) or perpendicular (vertical).

- Strength... The parameter corresponds to classes within M100 – M300, clinker type - M300 – M1000, stones from M25 to M300, stone and brick with horizontal voids - M25 – M100.

- Frost resistance. Any type of product can be produced with frost resistance F25 - F300.

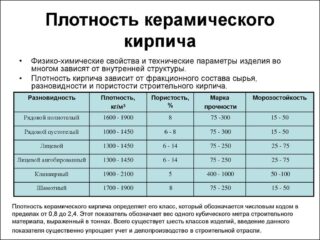

- Medium density... The parameter corresponds to values from 0.7 to 2.4.

- high, product density 0.7 and 0.8;

- increased - 1.0;

- effective - 1.2;

- conditionally effective - 1.4;

- ineffective (normal) - 2.0 and 2.4.

The more voids in the brick, the more air chambers in it. The air does not conduct cold well.

Dimensions (edit)

GOST defines all the sizes that the manufacturer has the right to choose for their products.

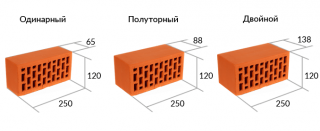

Table of nominal brick dimensions and their symbol.

| Item type | Designation | Dimensions in mm | Dimension symbol |

| Brick | KR | 250:120:65 | 1NF |

| 250:85:65 | 0.7 NF | ||

| 250:120:88 | 1.4 NF | ||

| 250:60:65 | 0.5 NF | ||

| 288:138:65 | 1.3 NF | ||

| 288:138:88 | 1.8NF | ||

| 250:120:55 | 0.8 NF | ||

| Brick with horizontal voids | KRG | 250:120:88 | 1.4 NF |

| 250:200:70 | 1.8 NF |

- length (non-working size) from 250 to 510 mm;

- width (working size) - 120–510 mm;

- thickness from 140 to 219 mm for unpolished stones and strictly 229 for polished products.

The size designation (NF) corresponds to how many times the brick indicated in the table is larger or smaller in volume than a brick of the usual format. For example, 1.4 NF (one and a half) with dimensions of 250x120x88 is 1.4 times more voluminous than 1NF (single brick 250x120x65).

Knowing the conditional dimensions helps in the design of buildings, as well as in calculating the required amount of material when purchasing.

Limit deviation of brick dimensions according to GOST shouldn't be anymore 4, 3 and 2 mm in length, width and thickness, respectively. The size of the sides of square voids should not exceed 20 mm, and slot-like ones - 16 mm.

Separate voids in the stone are made for easy grip when laying. This is not a defect if the area of the holes does not exceed 13% of the area of the bed.

Symbols

Example of designation: KR-r-by 250x120x65 / 1NF / 200 / 2.0 / 50 / GOST 530-2012:

- KR - brick;

- L - private;

- PO - corpulent;

- size 250x120x65 mm;

- 1NF format;

- 200 - strength grade M200;

- 2.0 medium density 2.0;

- 50 - frost resistance F50;

- GOST 530-2012 - issued in accordance with the technical specifications defined by GOST 530-2012.

Product marked KM-r 250x120x140 / 2.1NF / 200 / 1.4 / 35 / GOST 530-2012, reports that we are talking about an ordinary front stone, geometric dimensions 250x120x140 mm, density 2.1, strength M200, format 1.4NF, frost resistance F35, GOST number.

Technical requirements

Face brick made with at least two front faces (spoon and butt). This makes it possible to obtain a lined surface of any wall during masonry.

Vertical faces ordinary products are made smooth or embossed.

Face brick edges are smooth or textured by gunning, engobing, glazing, or made by two-layer molding.

Product color - from red to brown - determined by the manufacturer or negotiated in an agreement with a large consumer (wholesaler or developer).

Black core and dark contact spots on the surface - defects do not affect the quality, but are the result of production technology.

Density classes indicate medium density. The number indicates the maximum rate. For example, a density class corresponds to an indicator of up to 700 kg / m³, a density of 0.8 - 710–800 kg / m³, 1.4 - 1210–1400 kg / m³.

Mass deviations one cubic meter for classes 0.7, 0.8 and 0.9 can be +50 kg, for other types +100 kg.

- high efficiency corresponds to less than 0.2 W / (m · ° C);

- increased efficiency - 0.2 - 0.24;

- effective - 0.24 –0.36;

- conditionally effective - 0.36 - 0.46;

- ordinary - over 0, 46.

In determining strength class take into account the compressive and flexural strengths. The higher the number, the stronger the bricks.

Limit water absorption values correspond not more than 6% for clinker bricks and at least 6% for other types.

Water absorption parameters are important when designing buildings. The increase in mass when wet puts additional stress on the foundation of the building.

To check the brand of frost resistance the brick is soaked in water and frozen. The number in the marking corresponds to how many freeze-thaw cycles the products have withstood before cracking, peeling, chipping occurs.

How much does a red brick weigh

For an approximate weight calculation regular corpulent product recognize density, format and size ordinary red brick. The formula is: m = a * b * c * pwhere m - weight of one product, a, b and from dimensions, R - density

Substituting the values for solid brick M200, you can calculate its mass.

Another way is to calculate the volume of one brick, and then the number of products in a cube. Dividing the mass of 1m³ of products by the number of bricks, we get the weight of one.

From a practical point of view, there is no need to determine the mass of one brick. When designing, calculate the total volume of the walls minus the window and door openings and multiply the resulting figure by the density.

How many bricks are in the pallet

For transportation of red bricks use two types of pallets, their sizes: 1030х520 and 1030х770 mm.

The maximum packaging height cannot exceed one meter. Taking into account that the sizes of products may be different, you can determine the exact number of units by the product label.

Some data by weight of the package and the number of products on the pallet collected in the table.

| A type | Weight of one piece, kg | Net weight on a pallet, t | Pieces per pallet | Weight 1 m3, t | Pieces per 1m3 | |

| Private corpulent | single | 3,3–3,6 | 0,65–1,45 | 210–400 | 1,–1,85 | 513 |

| one and a half | 4 –4,25 | 0,8–0,85 | 200 | 1,5–1,63 | 380 | |

| double | 6,5–7,2 | 1,3 – 1,45 | 200 | 1,6 – 1,75 | 240 | |

| Private hollow | single | 2,3 – 2,5 | 0,8 – 1,11 | 350 – 445 | 1,2 – 1,3 | 513 |

| one and a half | 3 – 3,4 | 0,85 –1,15 | 290 – 350 | 1,14 – 1,25 | 380 | |

| double | 4,5 – 5 | 0,8 – 1,12 | 180 – 225 | 0,95 – 1,21 | 240 | |

| Facial hollow | Single | 1,3 – 1,6 | 0,64 – 0, 67 | 180 – 225 | 0, 98 –1,21 | 242 |

| one and a half | 2,7 – 3,3 | 0,95 – 1,12 | 350 | 1,02 – 1,63 | 380 | |

Density tolerances, different stacking options, different sizes and carrying capacity of pallets do not allow us to find out their number in a package with an accuracy of one unit. All the necessary data is contained in the packing label, with which the plant is obliged to accompany each packing unit.

Packaging, transportation and storage

The bricks must be placed on a pallet and packed in a way that prevents damage during transportation. Product covered with heat-shrinkable stretch film or other materials.

Re-grading is not allowed products in one packaging unit.

For transportation by cars with a carrying capacity of up to 7 tons, pallets are placed along the axes, on heavy trucks - in a checkerboard pattern. For transportation, vehicles with an open top are attracted, providing loading with a manipulator.

When loading manually piece goods proceed as follows:

- a brick is installed along the sides on the side face (spoons);

- the center is filled with products, laying them on the bed and placing the long side across the body.

Loaded vehicle speed should not exceed 80 km / h on the highway and not more than 40 km / h on unpaved roads.

Unloading with a dump truck will lead to a battle of up to 10-15% of the goods, therefore, unloading of packages is carried out with a manipulator, and a piece is removed from the body manually.

When storing, take into account that it is impossible to store products on the ground, the goods are stacked on pallets. During long-term storage, the film is not removed from the packages, and the goods brought in bulk are sheltered from precipitation.