The method of fixing the terrace board is chosen taking into account the operating conditions. In the process, the lumber dries out or expands under the influence of moisture. Fasteners for decking must create and maintain a technological gap of the specified parameters between the elements. A smaller gap will lead to swelling of the board ends, and a large one will turn into ugly cracks.

Open mount features

The easiest method for fixing decking to the support lags of the subfloor... Before installing the hardware, pre-drill a hole in the wood with a diameter of 0.5 mm less. Then a sweat is made under the cap - a depression in the diameter of the cap by 1.5 - 2.0 mm. The holes are usually putty with a suitable shade of exterior compound.

Use different hardware:

- nail lumber to the bars;

- screwed with self-tapping screws.

Choosing between open and closed way

The open method is easy to implement, while you can save on the purchase of special mounts. A beginner can use this method, while the boards will be laid exactly according to plan. The cost of the hidden method is usually 2 - 3 times higher than that of the open one.

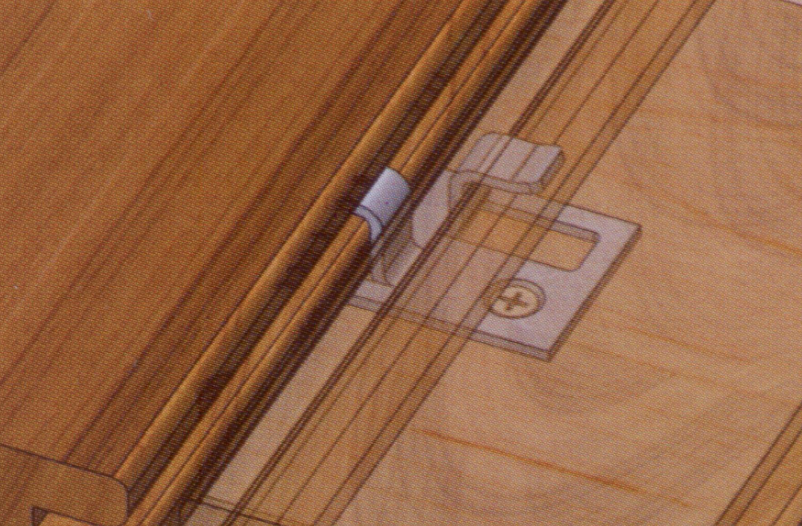

Closed version fasteners of various types are used, so you can choose the one that suits your particular case. The appearance of the floor will be neat and even. During operation, the boards will not move, since the fasteners will hold not only the body of the elements, but also the ends. The fasteners are fixed to the logs, then a decking (terrace board) is inserted into it or fixed to it.

To decide on the choice of method take into account factors:

- aesthetic appearance;

- the economic component of the work;

- the risk of wood warping;

- fragility of the selected wood.

Concealed mounting options

They release fasteners that fasten one board to the lag or hold two at the same time: the first and the next. Concealed installation takes more time, but builders choose it.

Distinguish types of fixation:

- slot type;

- spike;

- track;

- castle.

Groove method is the most convenient, but the speed of work is reduced. In the elements of the flooring, grooves must be milled. There is an option to speed up the process if the grooves are made in the workshop during manufacture.

Spike method used to a limited extent due to the recommended low density of wood.It is undesirable to use this option for boards made of wood treated with high temperatures, since the parts become fragile.

Track type fasteners keep the WPC boards from changing dimensions, turning in the plane as much as possible. The fastener is mounted with screws from the reverse side of the plank strips on the upper or side surface of the log. Installing such fasteners is an inconvenient job, especially if there is soil directly under the floor.

Lock type used for planken - slats with beveled or straight profiles of different widths and 20 mm thick. The latch is usually mounted from the back side of the board, then the elements are turned over, fastened additionally, all fasteners can be hidden in the floor. The surface will be perfectly flat and reliable.

Types of fasteners

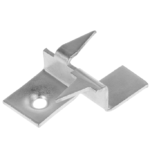

Most often, they put a fixing Key, which is called so because of the characteristic appearance of the corresponding shape. They are used for decking with a thickness of over 18 mm, thinner elements split during installation. Sturdy latch gives a smooth, durable finish.

Used by others types of fasteners:

- Cobra... Concealed stud-type fasteners. They are used for straight-profile boards made of soft wood species. The thickness of the lumber ranges from 18 to 22 mm, they are placed in hard-to-reach places, and the boards are also fixed at an angle of 90 °.

- Cat. Provides the fastest installation speed for 18mm softwood lumber such as pine. On sale there are varieties of metal with a galvanic or thermal diffusion layer on the surface.

- Snake. Belongs to the category of lock connections, released recently. The plate is installed on the back of the board, then turned over, the visible part of the plate is brought under the previously installed board, and the free part is attached to the log. The two boards are fixed together.

- Crab... Combined model of fasteners that combines the varieties of groove and lock connection. The contour created between the upper and lower flange of the retainer forms a solid structure. A tough duo resists internal tensions in the body of a tree.

- Bridge. They are used for decking with a straight or beveled profile, while the width of the elements should be in the range of 110 - 145 mm. The durable retainer is a profiled plastic plate with holes for self-tapping screws. The fasteners hold the flooring element, in addition, create a technological ventilated space for honey with a log and a board.

The Omega mount belongs to the groove type, allows you to mount boards with a straight end, an asymmetric or symmetrical groove in height. There are varieties that create a gap of 3 to 13 mm. The design of the retainer has a plate with holes and wings on the sides. Suitable for hard and soft wood.

Calculation of the number of components and lag

When choosing, pay attention to the presence of a limiter (stopper) to form and maintain the parameters of the gap throughout the entire service life. Such details are available for locking, spike, groove and track elements.

Do basic calculations:

- Lags. When the boards are installed in parallel, the gap between the logs is made 500 mm, if the boards are set at an angle of 45 ° - 300 mm, at an angle of 30 ° - 200 mm. Based on this, the number of support bars is counted by the piece. The section is chosen taking into account the quadrature of the terrace, the thickness and weight of the floor covering, the load from furniture, people.

- Clips. Elements are made of plastic or steel, mainly of aluminum or steel with an anodized zinc layer. One square of decking floor is usually counted on 22 pieces. For example, for an area of 12 m², you will need to buy 264 clips (12 x 22).

- Starting hardware. Fixing elements are installed on both sides of the balcony, terrace. Experts recommend mounting 4 pieces. per running meter of floor slats. For example, if the opposite sides are equal in length to 6 m (3 m x 2), 24 pieces (6 x 4) are required. Starter clamps are sold in packs of 20, so you need to purchase 2 packs.

- Self-tapping screws. The number of hardware depends on the number of fasteners that will be needed when installing the floor. Retainers usually have one screw hole, so they are counted by the number of fasteners. If there are two self-tapping screws in the fasteners, the number of hardware is calculated accordingly. To do this, you need to know the type of fastener, the method of fixing it to the board and the lag.

An example of calculating material on an area of 24 m2

You will need to dial 24 squares of floorThis equates to 52 planks 3 m long in the direct installation method. Lags are taken with a length of 4 m, they need 18 pieces, subject to a section of 70 x 80 cm.

Material consumption per square meter gender:

- lags - 0.75 pieces or 3 rm;

- kleimers - 25 pieces;

- starting clamps - 4 pcs. per square.

Thus, for a square of 24 meters, you will need 600 kleimers, a start - 96 pieces, 7 pieces of corners with a side size of 4 x 6 m. Self-tapping screws will need 696 pieces, add another 70 pieces to fix the corners.

All calculations must be checked with the installation specialist. or from the store manager. Fasteners and self-tapping screws can be purchased at any time, and logs and decking will have to be ordered and wait for delivery.

We bought a Spax with a double stainless steel thread - no problem, there are crosses and a bit in the box, and a drill for a small head, and the screws themselves are double-threaded, and the color can be brown.