Laminated drywall is produced with a decorative film that looks attractive in the interior. With this method of facing, time and money are significantly saved, since the finished surface does not require sealing, puttying and painting.

Description of laminated drywall

Sheets are two standard sizes:

- 1200 x 2400 x 8 mm;

- 1200 x 3000 x 12.5 mm.

Laminated panels are used for finishing horizontal and vertical surfaces inside buildings, of which form door and window slopes... The material is set during manufacture partitions for allocation of zones in apartments, offices, public places.

Plates with decorative film are used when finishing decorative false fireplaces... Laminated gypsum board is suitable for wall niches, decorative shelves, built-in furniture.

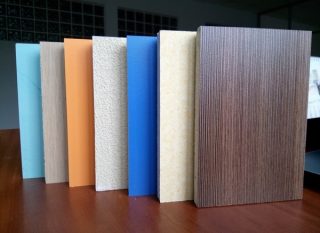

Basic color options

Decorative finishing options:

- imitation of different species from light to dark wood;

- stylization of the surface like marble, granite, basalt, other types of natural stone;

- uniform coloring without ornament, pattern, many color solutions are provided.

Manufacturers paint the material in accordance with the world RAL catalog... This is convenient for the user who chooses a color from this scale.

Methods for mounting LGKL on wall surfaces

Sheets are mounted in two ways:

- frame;

- glue.

In the first case, you can additionally insulate the room, install protection from external noise, moisture, steam. Frame pushes the wall into the room by 7-10 cm, therefore, in small rooms they use frameless way... The walls are carefully leveled with plaster under the sheets.

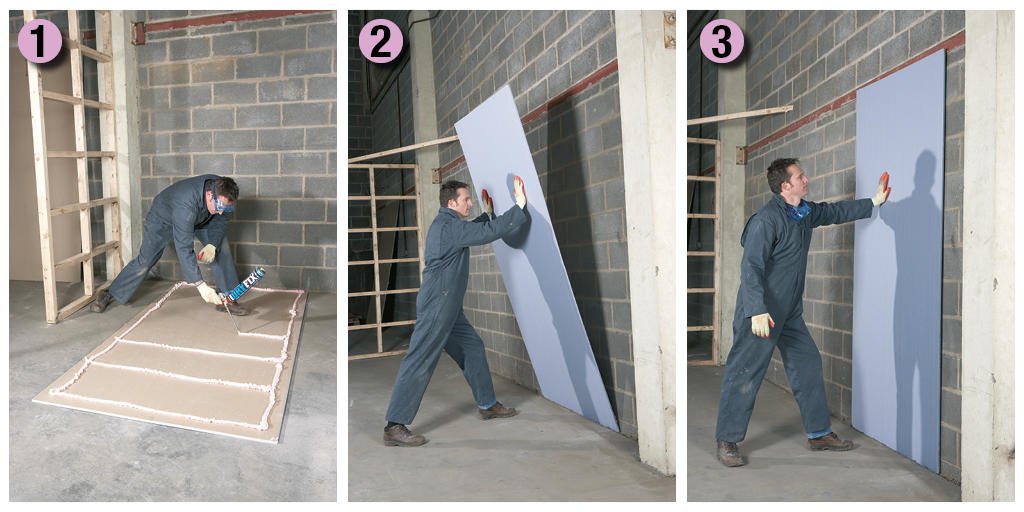

Frameless installation method

Installation includes processes:

- Preparing the walls. They remove the old finish, clean out irregularities, close up cracks, and be sure to prime the wall.

- Application double-sided tape. The tapes are glued vertically with discontinuous and solid lines so that they coincide with the edges of the sheets, so they make a preliminary marking. Intermittent tapes are placed 70 mm long with a step of 200 mm, and the distance between the vertical stripes is made no more than 200 mm.

- Plasterboard panels are placed vertically, while the edges should fit exactly on the tape. Fit the sheets with light pressure.

Second option suggests sticker material for glue mixturewhich is sold dry. The diluted composition is applied to the sheet in strips, the plate is raised, and it is placed in the mounting position.

Installation on a frame

The frame is mounted on the wall using a building level and a plumb line. The plane is exposed with the help of stretched cords in order to exclude protrusions and depressions of the profiles. For each sheet, 4 racks are calculated (step 40 mm)... For the frame, take wooden slats impregnated with linseed oil, or a galvanized metal profile.

To the metal profile sheets are fixed in two ways:

- on adhesive double-sided tape;

- with the help of guide inserts in the center, into which the side edges of the drywall are brought in from both sides.

In the second case, adhesive tape is glued to the ends of the laminated plasterboard sheets to protect against moisture. You can't just seal them up with putty..

After sticking the sheets on tape seams remain which are sealed with a sealant, then decorative stripes are glued. Internal or external corners are placed on the corner joints.

Cardboard sheets can be bent 90 °. To do this, make a cut from the inside, choose a mass of gypsum, fill it with a sealant and go around the corner.

Features of the operation of laminated drywall

Do not mount sheets on surfaces that are wet during service, for example, on the walls of basements, basements with poor waterproofing.

Regardless of the fastening method, the recommendations for the care of the material:

- the unprotected upper and lower ends of the sheets must be treated with moisture-resistant impregnations or waterproof adhesives;

- clean the surface with the use of liquid detergents, use a damp foam sponge, avoiding smudges;

- Do not use abrasive scouring powders to keep the vinyl intact.

The tape increases the resistance of the material to impact, abrasion, but it is not recommended to deliberately allow mechanical stress.