Power lines allow the transmission of electricity over long distances. In addition to cables and electrical equipment, fittings and support components are also required for their arrangement. The latter can be reinforced concrete, steel or cast iron. Linear reinforcement connects cables to each other, allows you to create garlands of insulators and include them in the line structure, and also protects its components from mechanical deformation.

General information and requirements

Power transmission line fittings made from various alloys and produced in a wide range of products for various tasks... In addition to steel and cast iron parts, you can also find spare parts from non-ferrous alloys. The production of fittings in factories, their transportation and storage are regulated by special documents. In accordance with GOST 13276-79, the following spare parts are presented the requirements:

- Sufficient level of fatigue resistance and no tendency to crack. These characteristics determine wear resistance fittings. It is important that the parts withstand light electromechanical shocks when electric current flows through the cables.

- Mechanical strength, retention of shape when force is applied.

- For hinged parts capable of turning in the horizontal and vertical planes, sufficient the amount of mobility and its retention throughout the service life.

- Products must be very corrosion resistant, since most of them have to be outdoors and regularly come into contact with precipitation. If the surface rusts, the electric current is less conductive. This can cause line failure.

- Parts that will be in direct contact with current must have sufficient electrical conductivity... The higher it is, the more efficient the lines work. An insufficient indicator leads to a drop in current or voltage on a section of the circuit. Other parts, on the other hand, must have insulating properties.

Such fittings are produced on special machines of increased powerwhich are large in size and consume a lot of electricity. Less resource consuming way - rolling.

When purchasing fittings, you should pay attention to the certificates of conformity and other attached documentation.

Varieties of linear fittings

There are several types of linear fittings that differ in purpose and structure. The parts you purchase depend on your power line configuration.

Linear couplings

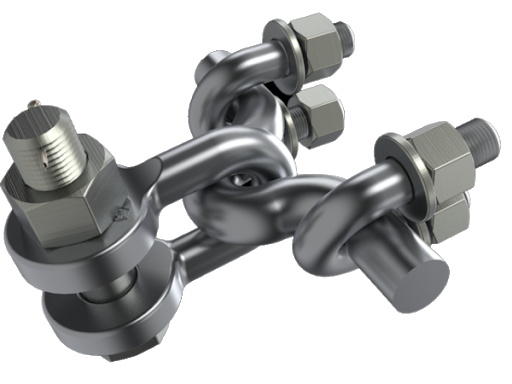

Performs extension and connection functions... Such parts allow you to increase the length of the garlands, combine a number of them into a monolithic chain, fix the clamps for connection to the insulating block. Also, couplings are suitable for fixing garlands on supports and distributing the weight of the latter on several independent points. Hinges are used to connect parts.Chain parts help the structure to rotate in a vertical or horizontal plane. The use of spherical joints is also possible.

Protective fittings for overhead lines

Often takes the form rings or slingshots mounted on garlands... In low-voltage areas, such parts are rarely used, while in places with very high voltages (330 kV or more) they are required. In circuits with indicators in the range of 220-330 kV, they often use bit hornsensuring the stability of the installation in case of deteriorating weather conditions. Sometimes they put on intermediate supporting elements U-shaped clamps. Protective parts are used to level vibration, stabilize voltage on complex fragments, protect against mechanical damage, rain and wind.

Connecting elements

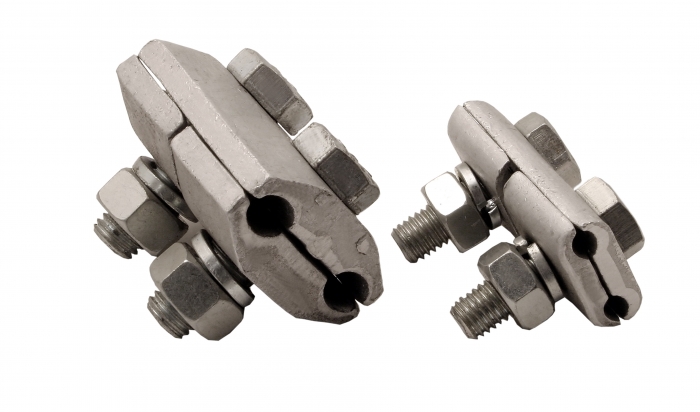

Are used for tying individual cables and wires... Often used hollow cylindrical parts made of aluminum inside. To tie the wires, they are inserted into the pipe, crimped and fixed with hold-down devices. There are also thermite cartridges that tie the cables into special loops. The fired paste partially melts the metal, which results in a reliable seam. The group of connecting parts includes a large number of clamps (for example, ram, grounding, canine-shaped and others). Some of them receive only an electric current load, while others have to withstand a mechanical one as well.

Tension fittings

Used by for connecting wires and cables to pulling garlands... This includes, for example, such clamps as wedge (it can be designed for different wire cross-sections) and bolted. They are subject to stringent requirements in terms of size and level of strength. These parameters should match those of the string being pulled. Clamps must provide stable electrical contact and also handle the transfer of stress from cables covered with ice or blown by the wind.

Supporting parts

Intended for fastening cables and ropes to garlands intermediate support elements... The mount can be completely rigid, or use a release clip to allow the wire to fall out if it breaks or if the string has noticeably deviated from the vertical. Swing clamps are also used, in which the cable is fixed in a structure similar to a small boat. For different types of supporting products, special specifications are developed, taking into account the weight of the wires, their thickness and the magnitude of the breaking load.

Contact fittings

Used in particular for connecting cables and wireslocated in the loop of the anchor support. This group includes clamps for branches, as well as hardware and intended for grounding.

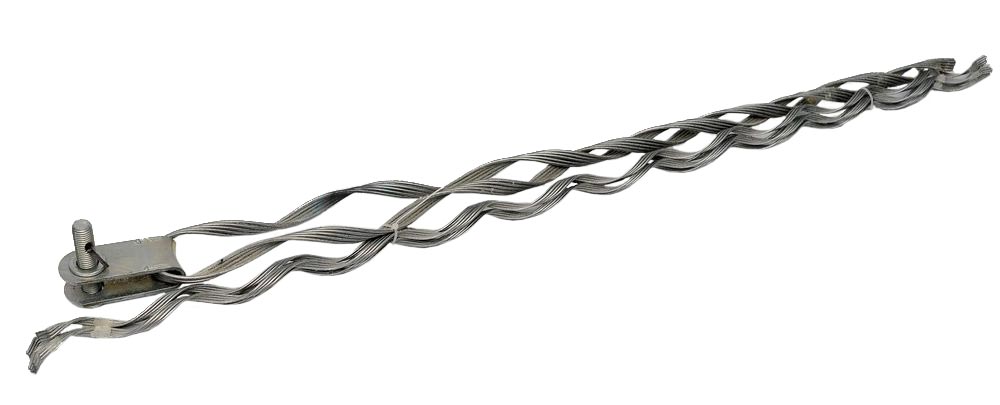

Spiral reinforcement elements

Are used for hanging wires on supporting elements of overhead lines... In the United States, they have been known for more than half a century, but in our country they began to be produced only about 20 years ago. They are suitable not only for power transmission lines, but also for optical lines. Installation is fairly easy and does not require special equipment, while the supplied load is distributed over a large area of the conductor. However, with a small distance to the cables of the line itself, it is difficult and unsafe to mount such parts. On optical lines, such parts are used only on round cables. The fastening method used in spiral reinforcement protects against vibrations, excessive friction and kinks.

Criterias of choice

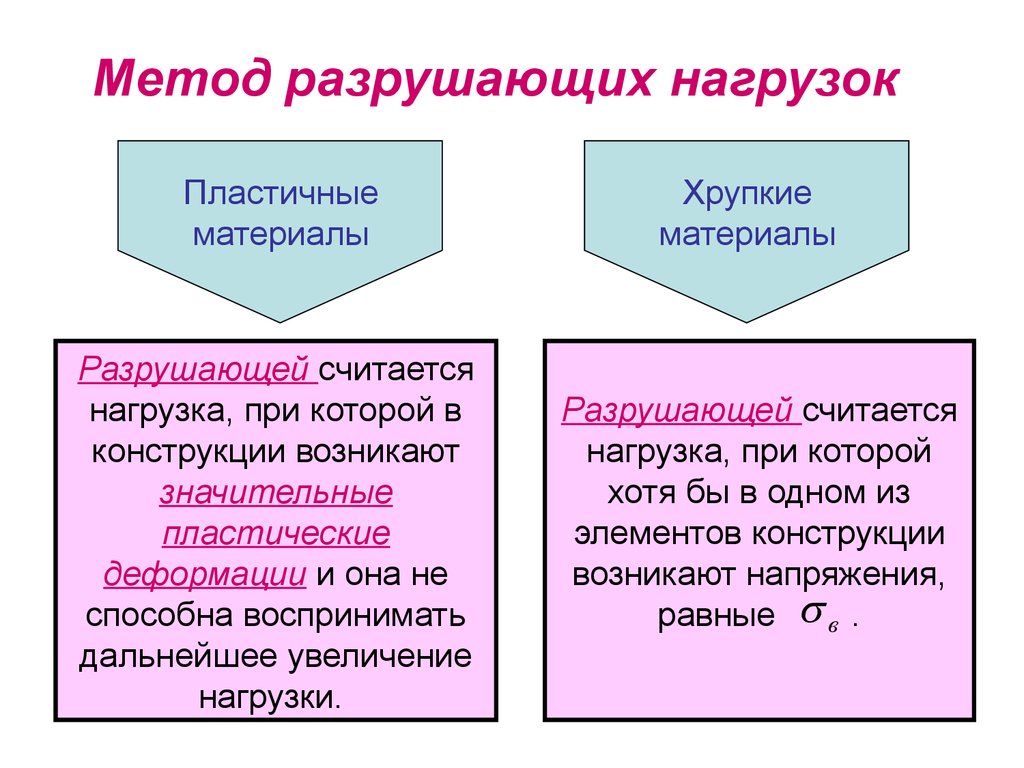

Reinforcing parts for the cable and for the wire are chosen in the same way, while it is necessary to follow the recommendations given in Electrical installation rules... To calculate insulating parts, use breaking load method, in this case, calculations without correction for ice and with its use are performed separately. It is also important to know the destructive electromechanical load.

All coupling components tested for tensile strength through calculations. Vibration damping parts, tension and support clamps, and spacers are selected according to the thickness of the wires... The holes in the supports are made so that the components of the assemblies are located freely, with the minimum possible clearance.

Ears, staples, details for fixing the garlands to the supports are selected according to safety factor... During normal operation of the line, it is 2.5, while operating in emergency mode, it is 1.7.

Since the coupling parts are provided with hinges at the ends, they must be relied upon to apply a tensile force. Calculation for bending load (reflecting the state during long-term routine operation) is relevant only for fixing units of insulators to supporting elements.

Installation and operation rules

When a valve fails or is taken out of service, it is recommended hand over for processing.

On sale you can find products designed for operation, including in extreme frosts (up to -60 degrees), however, installation work still needs to be carried out at a mild temperature (the limit is -20 degrees).

Most clamps are designed to be demountable, but does not involve secondary installation... For some branch parts, multiple mounting and removal of cables is possible.

Shorting devices must be put into the case immediately after use. Sometimes on conductive cores they install power limiting devices.