Fibreboard is a medium density sheet material. MDF ceiling panels are made from wood-processing waste, which is pressed with the addition of modified carbamide resins. The process takes place at high temperature and pressure.

- Features of MDF ceiling panels

- Dimensions (edit)

- In what premises are used

- Varieties of panels

- Veneered

- Laminated

- Waterproof

- Painted

- Paper coated

- Design

- Colors

- Criterias of choice

- Instructions for installing MDF on the ceiling

- Preparatory work

- Tools and materials

- Installation steps

- Plinth installation

- Ceiling design examples

Features of MDF ceiling panels

MDF boards have an average cost, they are more expensive than budget fiberboard products, but they have good performance characteristics. The finished finish is indistinguishable from natural wood. The coverings on the sheets are made in several versions.

Dimensions (edit)

Standard panel sizes:

- width 56, 238 and 250 mm;

- the length is almost always 2600 mm.

Despite the fact that manufacturers, based on GOSTs and norms, develop their own technical conditions (TU), the dimensions of the panels do not differ, they are universal.

In what premises are used

MDF ceiling panels look beautiful and appropriate in various rooms. When choosing, take into account the characteristics and appearance.

Application options:

- painted slabs are suitable in the children's room, creating a colorful design;

- material with imitation of wood is used to decorate the ceiling in the corridor, kitchen;

- in the living room or bedroom, panels with a gloss of light color are used so as not to burden the space;

- in the bathroom, only a moisture-resistant type of MDF finish is installed.

The shiny surface is combined with various types of built-in lamps, visually increasing the height of the rooms. In addition to residential premises, such ceilings are installed in offices, in factories, in public buildings. For an original design, specialists combine several types of panels, use other materials.

Varieties of panels

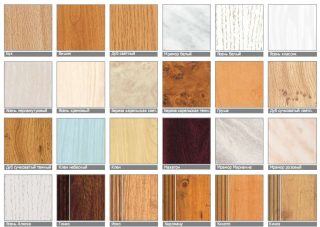

By type of coating on the front side distinguish between:

- flat products, on one side of which a film of polyvinyl chloride (PFC) is glued, the layer is called lamination;

- sheets with veneer coating;

- embossed products with an embossed pattern that is varnished to enhance perception;

- smooth slabs, the surface of which is painted with colored compounds.

There is a material that includes water repellents anti-water absorption and paper-coated material.

Veneered

Difference from natural wood panels:

- products do not shrink, do not shrink;

- do not dry out over time;

- flammability is reduced, moisture resistance is increased.

Veneered material from natural wood can only be distinguished by close examination.

Laminated

Characteristics of laminated boards:

- increased water resistance;

- beautiful view;

- resistance to light, some chemicals.

The texture relief depends on the thickness of the coating. A thickness of about 200 microns allows for embossing, emphasizing, for example, the grain of the wood in the picture. Such plates look natural and complement any interior.

Waterproof

Distinctive features:

- drops of water on the surface do not spoil the product;

- panels do not deform at high air humidity;

- the surface is easy to clean, does not require complex maintenance.

The waterproof version on the ceiling will last about 10 years, while maintaining the declared qualities.

Painted

Painted slabs used in dry rooms:

- in bedrooms, halls, living rooms, offices;

- in offices, trade pavilions, libraries, halls.

It differs in brightness compared to imitation of natural materials, therefore it finds its niche when decorating rooms with an original design. The surface can be repainted several times, if the concept of the room changes, the color needs to be updated.

Paper coated

Paper coating properties:

- does not fade in the sun;

- keeps well in dry rooms;

- the ceiling made of MDF panels with a paper layer has the lowest price.

In rooms with a high vapor content in the atmosphere, such plates are not used. For example, in the kitchen and bath, they will quickly swell and lose their appearance.

Design

There are product options that mimic glass seamless surface, such ceilings visually increase the space. For high-tech style, ceiling coverings are installed, the sheets of which are made under the metal... There are products with an openwork pattern that also look good indoors.

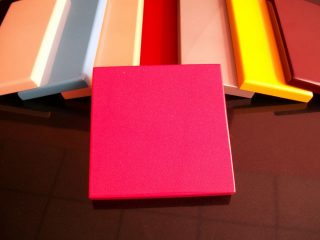

Colors

A huge variety of shades and colors allows you to choose the right color when decorating the ceiling. There are painted MDF sheets that look bright. The color of the tree is also pink, brown, with a green or yellow tint. There are panels for whitewashed or ebony.

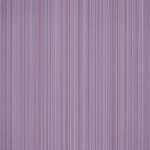

Depends on the color of the products on the ceiling feeling and mood of a person:

- green ceilings soothe, so they are placed in the office, bedroom;

- brown use light colors, because saturated suppresses;

- lilac color increases activity, its cold shades give confidence;

- purple shades are suitable for different rooms, but you need a combination with other colors in the interior.

there is yellow panels of different intensities, they all give a feeling of joy, warmth, improve mood.

The ceiling of any color must be matched with furniture and decor elements. Each manufacturer provides a catalog for selection.

Criterias of choice

At the time of buying check every packageto reveal imperfections and shade matching. It is better to purchase goods from one batch so that there are no such discrepancies.

Controlling moments:

- the integrity of the castle joints;

- evenness of slatted panels;

- lack of swelling from moisture, warping.

Ceilings are more often made light woodso as not to build up the atmosphere. Dark coatings look original at first, then get bored. For small rooms, options in the form of narrow slats are suitable, and in large living rooms you can use strips 250 mm wide.

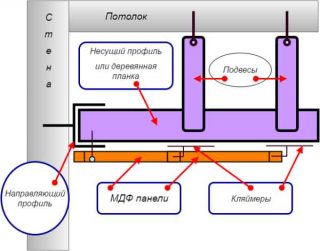

Instructions for installing MDF on the ceiling

Panels install on the crate by the type of suspended cover. The type of frame depends on the shape and size of the panels. The lathing is installed across the panels, and under the slab material, the slats are mounted in the form of squares. Their dimensions are taken so that the side of the element lies exactly in the center of the rail.

For the frame, apply:

- a wooden lath with a section of 40 x 25, it is pre-impregnated with linseed oil for 2 - 3 times;

- galvanized profile from the g / cardboard fastening system.

The slats and profiles are fixed to the ceiling with brackets, so that it is convenient to level the plane.

Preparatory work

Step by step markings for ceiling mounting:

- they plan to lower the ceiling, take into account the installation of built-in lamps;

- beat off the perimeter of the lower layer along the walls, apply a level;

- lines are marked on the surface of the floor slab for fixing the ES brackets;

- start work on one side, move to the opposite.

For marking, threads are used, which serve to align the battens in one plane.

Tools and materials

The brackets are fixed to the ceiling dowels with self-tapping screws. For panel mounting use kleimers, which allow you to make a seamless coating, disassemble it if necessary without damaging the material.

Use instruments:

- puncher, screwdriver, drill;

- tape measure, bubble level, laser;

- screwdrivers, a regular hammer and a mallet;

- hacksaw or electric jigsaw.

If staples are used, a stapler is added to the tool list. You also need a brush to treat the surface from mold and mildew.

Installation steps

Further procedure:

- the UD-25 strapping profile is fixed to the walls along the perimeter;

- CD-60 profiles are inserted into it with their ends, set with the help of suspensions according to the level, check the plane;

- profiles are joined together by connecting elements, cross-shaped parts are used;

- MDF boards are fixed to the frame, fastened with clamps, brackets or self-tapping screws.

First, one strip is fixed, a second panel is inserted into it, all the elements are gradually fixed.

Plinth installation

Foam elements put on glue trying to apply so that it does not squeeze out, does not spoil the surface of the ceiling. The corners are cut with a miter box, a saw with fine teeth is used.