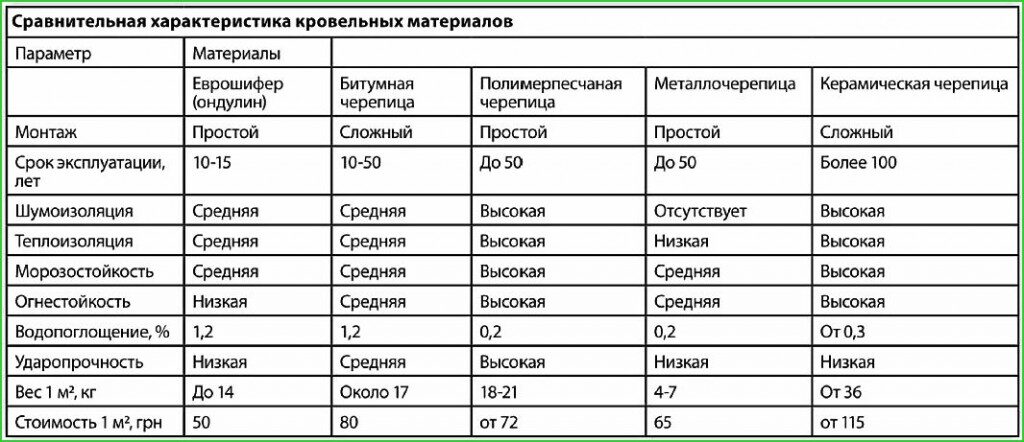

The choice of modern roofing materials is very large. Among them, preference is increasingly given to elastic flooring. They are easier to install and have better waterproofing properties. One of these materials is ondulin.

Onduline coating

Material steel produce in the 50s of the last century... The manufacturing technology has changed somewhat since then. To obtain a durable, beautiful and waterproof coating, literally waste is used: waste paper and mineral additives.

Waste paper is processed, they are made into pulp. The mass is placed in special containers, where it is dried, and then the resulting sheet is compacted and given a wavy shape. Blank impregnated with bitumen-polymer mixtureswhich make the base waterproof and UV resistant.

The sheets are painted. The color scheme matches the RAL palette, so that the right option can be selected for any building.

The material is often called euro slate, which is not entirely true. Thus, they only emphasize the environmental friendliness of ondulin.

According to the installation rules, walking on the flooring is strictly prohibited. This is especially true for wet ondulin, since at high humidity it loses its strength.

Recommendations for choosing ondulin

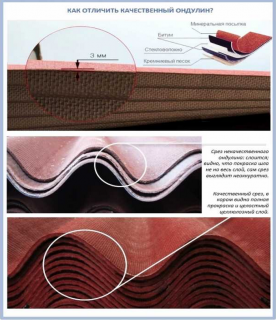

- All sheets the package must contain the same size and meet the standards: to have the required number of waves, specified thickness.

- Very important estimate sheet thickness, at least selectively. It should be the same throughout the fragment. You need to compare material not from one package, but from several, but from one batch.

- Pay attention to staining: it should be uniform. The shade must be the same for the whole batch.

- It is preferable to buy ondulin from manufacturers or their authorized representatives.

The manufacturer guarantees the water resistance of the material for a certain period. Color or mechanical resistance is not covered by the warranty.

Roof calculation

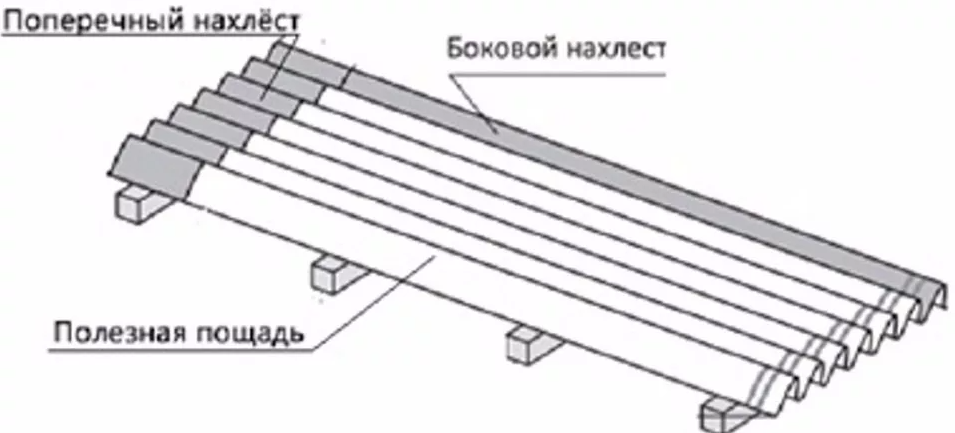

The installation instructions for ondulin do not contain calculation methods, but indicate the specifics of laying. Sheets must be placed not end-to-end, but with an overlap... The overlap of ondulin is 2 waves... Above and below, when laying next to each other, an overlap is made not less than 14 cm... In addition, the lower row of sheets along the edge of the roof is released outward by another 7 cm.

When calculating the volume, one has to take into account that effective leaf area will be less than its physical area.As a result, with a length of 2 m and a width of 0.95 m, the actual area of each flooring element will not be 1.9 m², but only 1.6 m².

The smaller the angle of inclination, the more you have to overlap. The result is:

- with a slope of up to 10 degrees, the sheet covers 1.29 m² of the roof;

- from 10 to 15 degrees - 1.54 m²;

- more than 15 degrees - 1.56 m².

The total area of the roof of the house is divided by the useful area of the sheet and the result is increased. by 5-10%to compensate for possible fight or material clipping. Then the number is rounded.

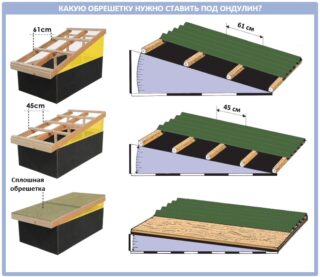

How to make a crate

- At an angle above 15 degrees, a sparse crate is constructed with a distance of 60 cm between the boards.

- If the angle is 10-15 degrees, the step is reduced to 40 cm.

- For a slope with an inclination of less than 10 degrees, a solid crate is made from a board or plywood.

For the lathing take well dried wood, it is desirable conifers... It contains a lot of resin, which increases its resistance to rot and mildew. The timber must be impregnated with antiseptics before laying.

How to properly attach ondulin to the crate

Installation of ondulin and shingles begins from material cutting... Very rarely it is possible to lay the roof only in whole fragments. For cutting, take the usual hacksaw or saw with a medium-sized tooth. You need to cut the material on a flat surface.

The steeper the slope, the more difficult it is to move and lay the material. Step-by-step instruction next.

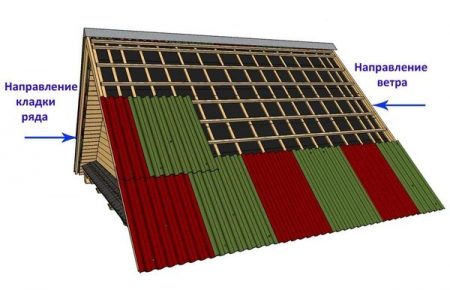

- Laying sheets starts from the bottom of the ramp on the leeward side. Sheets in a row are placed as evenly as possible with an overlap of 2 waves. Ondulin is laid so that an overhang of 5-7 cm wide is formed.

- The ondulin is fastened with roofing nails.... They are hammered into the crate through the crest of the wave. The length of the fasteners must be sufficient to reach the lathing and go 5–10 cm deeper. Up to 20 pieces are needed per sheet. 10 of them are nailed to the bottom edge. In the middle and upper, 5 pieces are screwed in, placing them in a checkerboard pattern. The fasteners are made non-rigid.

- Sheets of the second row and the next are laid so that the joint between the elements of the previous row is in the center of the next one. The seams of the rows must not match.

- At the junction points, additional waterproofing is used, for example, a special tape.

To get down from the roof, completely covered by ondulin, you need to take the stairs. It is allowed to move only in the place of the rafters.

Additional elements

- For skate and tongs special devices are available. They are also made of ondulin and fastened with nails.

- If the roof has interior corners, you will need valleys... The element is rather difficult to install. Under the gutter, it is necessary to mount a continuous lathing with the dimensions of the sides not less than 25 cm on each side of the corner. The endows are attached to the crate, the fragments are overlapped.When laying, the sheets are cut off when joining at the inner corner so that the edges of the ondulin do not reach the center of the valley, 5 cm on each side.

- Junction points - to the ventilation openings, chimney, close up with covering aprons.

If it becomes necessary to fasten ondulin to metal elements, self-tapping screws are used.

Waterproofing and vapor barrier

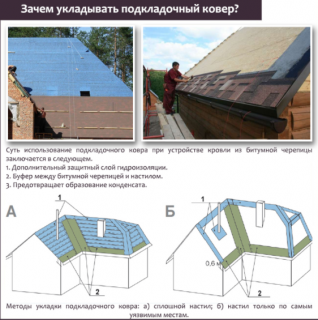

In order for such a roof to last a long time, equip lining carpet. It necessarily includes waterproofing. Most often used film material... The film is laid on the crate from top to bottom from the ridge to the overhang. The joints are glued with tape or welded with a construction hairdryer.

Vapor barrier is set in the event that if the roof is insulated... The barrier is mounted on top of the insulation. It allows steam to escape from the room through a layer of insulation, but cuts off the penetration of steam into the heat insulator.