The installation of profiled metal begins with the device of the correct lathing, the section and the pitch of the elements of which are selected depending on the slope of the slopes, the snow load and the wave height of the corrugated board. The technology of mounting the profiled sheet on the roof is simple, but you need to accurately calculate the working area of the elements so that the dimensions converge when laying. You do not need a crane to lift the lanes, but you will need 1 - 2 assistants.

- Features of the choice of material for the roof

- Preparing sheets and moving

- Influence of roof slope on brand selection

- Roofing technology and safety engineering

- Sheathing, waterproofing, sheet laying

- Working with additional elements

- Endova and valley plate

- Pipe aprons

- Dormer windows

- External internal corners, abutments, end, cornice strips

- Snow holders

- Skate installation

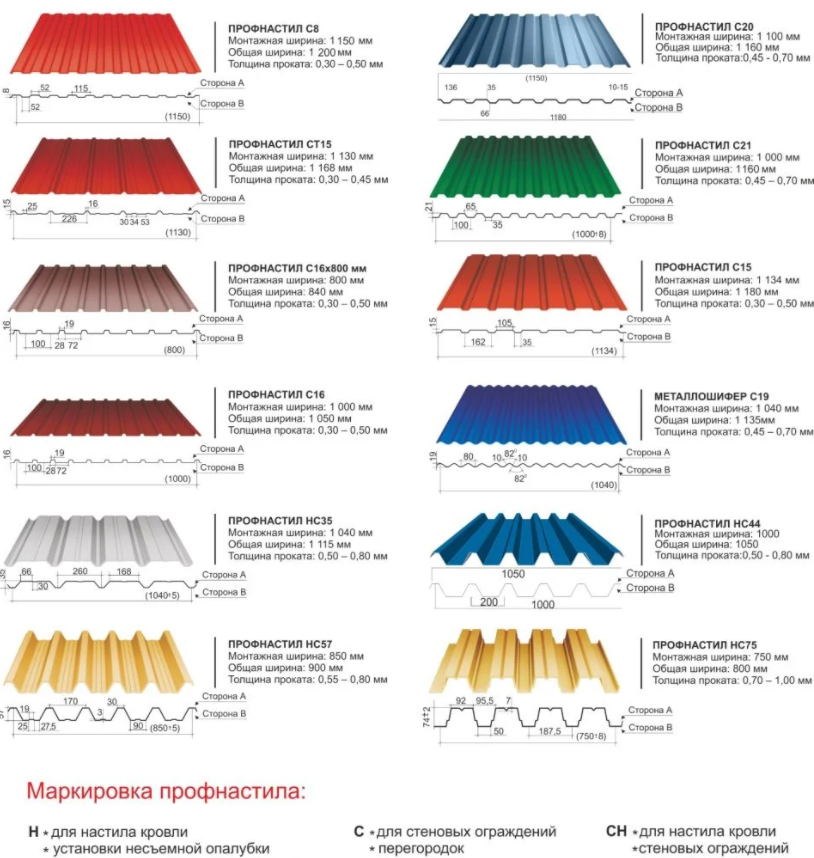

Features of the choice of material for the roof

They put on the roof of the house polymer coated profiled sheet... Galvanized sheets serve for about 20 years, such flooring can be laid on the roof of outbuildings, garages.

Chosen taking into account the operation:

- in areas with strong winds and snow drifts, material is laid with a wave height of 40 - 60 mm (H40 - H60);

- on flat single-slope and dual-slope ones, you need to lay the HC60 brand;

- for fences and facades, a wall profile with C8 - C21 is sufficient.

The coating on the metal profile has a service life of up to 30 years.

Preparing sheets and moving

Usually, the installation of corrugated board begins immediately after the arrival of the order, but sometimes the material needs to be stored if the rafter system has not yet been made or the weather does not allow.

Storage and movement rules:

- do not remove the packaging;

- transverse bars are placed under the strips in increments of 0.5 meters so that there is no sagging;

- kept indoors;

- lift the sheets, holding by the edges along the entire length, at least 3 people are needed;

- not dragged to maintain the integrity of the polymer layer.

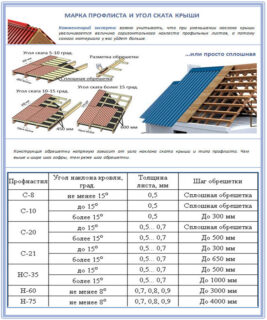

Influence of roof slope on brand selection

The overlap of the corrugated board along the length of the strips depends on the slope:

- the slope is less than 15 ° - the amount of shift is from 20 cm;

- tilt 15 ° –30 ° - overlap 12–20 cm;

- more than 30 ° - 10-15 cm.

On roofs with a slope of less than 12 °, a sealant is used at the joint to avoid moisture penetration into the under-roof space and into the attic.

Roof technology and safety engineering

The coating device is combined with the following procedures:

- stacking insulation (do not put in cold versions);

- gasket waterproofing and windproof membranes.

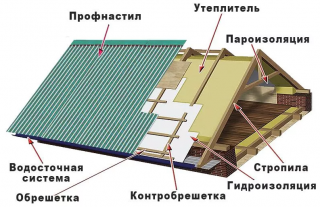

Sheathing, waterproofing, sheet laying

More often use wooden slatsto make the installation of a roof from a corrugated sheet, and metal corners are used in the case of a steel support structure. In the docking nodes, nails, self-tapping screws are used, and staples are placed. The slats are connected on rafters; it is impossible to dock in the air.

They put under the corrugated board insulation:

- placed between the rafters (slab);

- stuffed on the rafters, if rolled, while making a counter lattice for ventilation.

Waterproofing film they are fixed with a stapler if they are laid on wood, and self-tapping screws are twisted for metal.

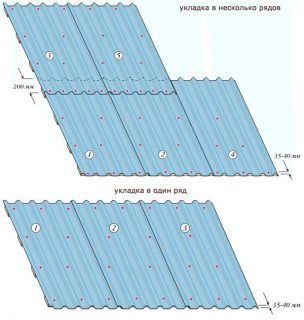

- the first strip is fixed at the ridge;

- the second is placed side by side, make up an even bottom line;

- the overlap is fastened along the top of the corrugation under the first fold across the sheet;

- install 3 - 4 elements in this way, check the cord, then put the rest.

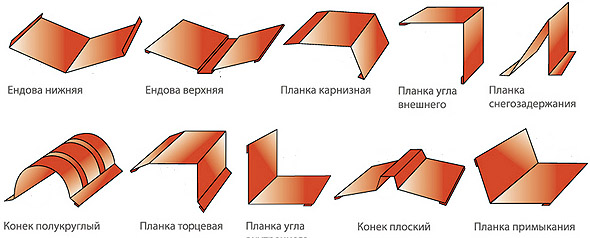

Working with additional elements

The roof is covered with a profiled sheet with the use of additional linings and linings in order to beautifully and reliably organize joints, abutments, exits to the roof of ventilation, heating pipes. The usual length of such profiles is 2.0 m for polymer-coated corrugated board, and 2.5 m for galvanized sheets.

Between the coating and the additional strips, a seal is placed made of a material that allows steam to pass through.

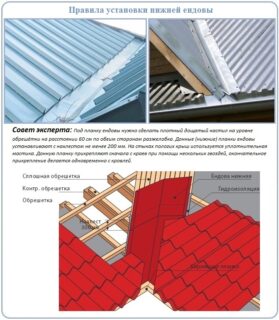

Endova and valley plate

Step by step installation:

- the valley is installed under the profile at the junction of the sheets;

- mount the main coating so that the edges converge on the lining with the substitution of the sealant;

- a decorative overlay is placed on top of the joint, also through a seal.

All water streams converge in this place, therefore, special attention is paid to the design.

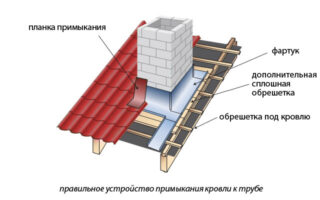

Pipe aprons

The apron model depends on the scheme of the passage unit according to the project and the wave height of the corrugated board and the configuration.

The product consists of made of a thin sheet of coated metal... It is often made on site from galvanized steel.

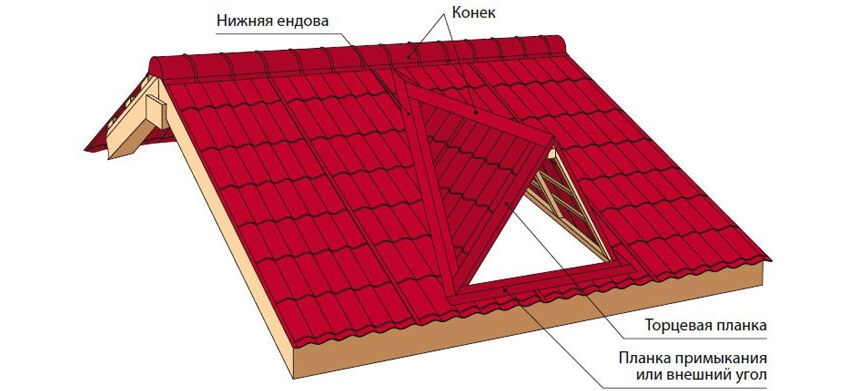

Dormer windows

These elements also protrude from the roof covering. Docking points need to be drawn upso that rain and melt water does not enter. To do this, use bottom gutter element, which is installed under the upper strip when installing the roofing profiled sheet. The grooves surround the dormer around the perimeter, no matter how complex the window structure may be.

External internal corners, abutments, end, cornice strips

The elements are mounted from the side of the roof overhang, towards the ridge, where the excess length is cut off. The end plate is fixed to the end board and corrugated board in the crest of the corrugation.

Additional planks are placed in places:

- adjoining the roof plane to the parapets;

- when changing the direction of the slope;

- at a turning point in the slope of the roofing plane.

Use wood screws 4.8 mm in diameter, 50 - 60 mm in length, they are placed with a step of 30 - 50 cm. The overlays are attached to the wall in a previously made line, or hidden under the finishing layer.

Adjacent parts are straight and angled. Their task is to protect the under-roof gap from precipitation, dust and debris.The flow of water through the elements goes in the right direction, is discharged to the roof covering or enters the gutter. In difficult cases, with a broken roof, sealants are used for external use.

Snow holders

Products are needed to organize the gradual snow melting without heavy icy boulders falling from the roof.

Varieties of snow holders by design:

- tubular;

- lattice;

- drag (toothed);

- corner;

- logs.

Items set simultaneously with the installation of the flooring, use shock-absorbing seals. The step between different types of snow holders is taken by calculation depending on the slope of the slope, the waveform and its size in height.

Skate installation

Installation rules:

- the upper crate is placed so that a gap of at least 5 cm is provided between the planes of the slopes;

- the last part of the lathing under the ridge is made with boards, or slats are placed in the bowl.

For protection, use factory elements or roofing galvanized metal with a thickness of at least 0.7 mm. It is bent at an angle of 90 °.