Facade cladding has 2 functions: it protects the walls from moisture, sun and frost and makes the building look attractive. There are many options for such a finish. One of the most popular is plastic facade panels.

- The advantages of installing PVC panels on the walls

- Selection of panels for installation on the frame

- Preparatory work before wall mounting

- Fastening to a metal profile

- Installation of panels on a wooden frame

- Installation nuances

- How to properly join PVC panels along the length

- How to join panels in the corner

The advantages of installing PVC panels on the walls

One of the advantages of the material is simplicity and ease of installation. Features of wall cladding:

- The elements are joined to each other using the "thorn in the groove" mechanism, which excludes incorrect installation

- The tightness of the bond guarantees a high mechanical strength of the resulting surface.

- The joints between the panels are not visible, so it is difficult to determine from the outward appearance which house is clad with clinker and which is with plastic siding.

- The panels are large enough - from 2 m² in area, but weigh very little, which greatly facilitates assembly.

- Installation of PVC panels can be performed by a beginner.

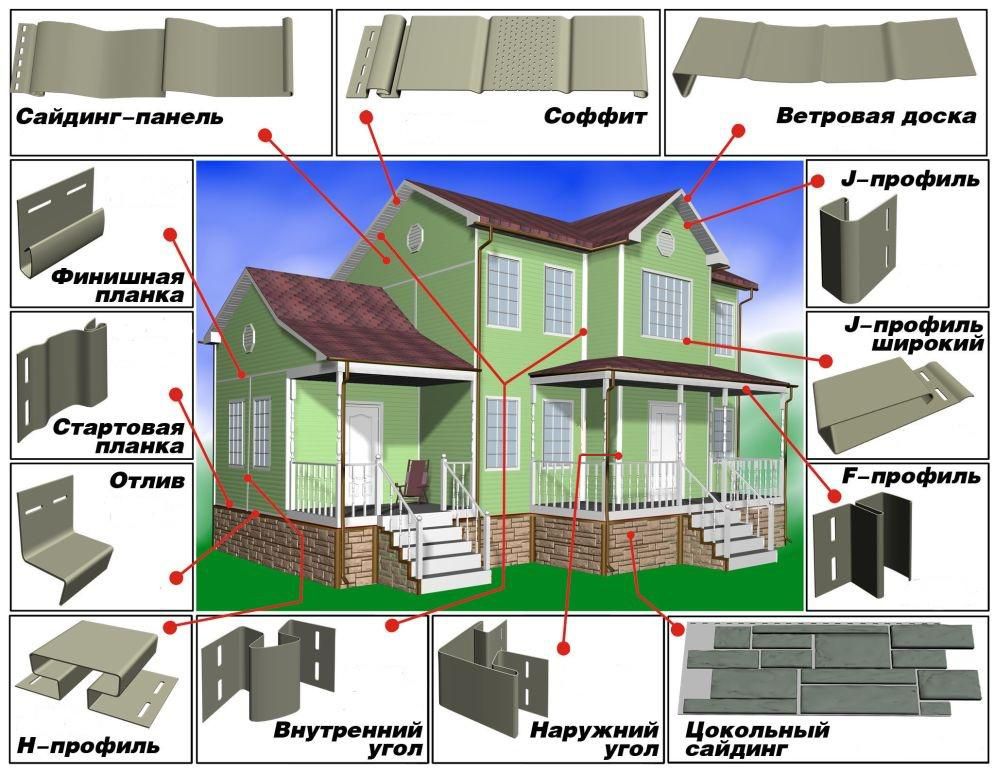

In addition to the sheets themselves, enterprises also produce all the necessary additional elements of the same kind and kind. There is no need to puzzle over how to frame a window or doorway, how to join siding at the corners.

Selection of panels for installation on the frame

Frame installation assumes the presence of an air gap between the wall and the cladding. This makes the finish somewhat vulnerable to strong side winds and slanting rain. Mechanical shocks can cause more significant damage: after all, the load on the panels is not perceived by the wall.

For mounting on a frame, choose a material taking into account the following considerations.

- Better to take maximum thickness siding - 10 mm. At the same time, the weight of the panel hardly increases, and the rigidity increases.

- Preference is given to two-layer options... The top layer provides protection against moisture and frost and a beautiful appearance, while the inner layer guarantees the rigidity of the base and the preservation of geometric dimensions.

- It is better to choose a siding that includes special additives and has the highest frost resistance. The material can withstand cooling down to -60 ° С, and it allows to perform cladding at temperatures below -10 ° С.

It is allowed to take panels based on polyurethane foam with a denser top layer. This option guarantees the retention of heat with a high wind pressure. It does not replace the insulation, but it neutralizes the effect of the wind.

Preparatory work before wall mounting

Installation of plastic facade panels begins with wall cleaning. Its surface should be relatively flat and free from defects. The facade is cleaned of dust and dirt, dents and chips are repaired with plaster. You can completely plaster the wall, thereby smoothing out the irregularities.

Second phase - markup... The cladding only fulfills its role when it is mounted correctly, that is the transverse strips are located strictly vertically, and the longitudinal strips are strictly horizontal, and not at all parallel to the ground surface. Therefore, to determine the bottom mark, measure the height of each corner. Find the smallest one, measure 5 cm from the ground level and put a mark. It is transferred to other corners with a laser level and connected by straight lines. This is where the bottom rail is attached.

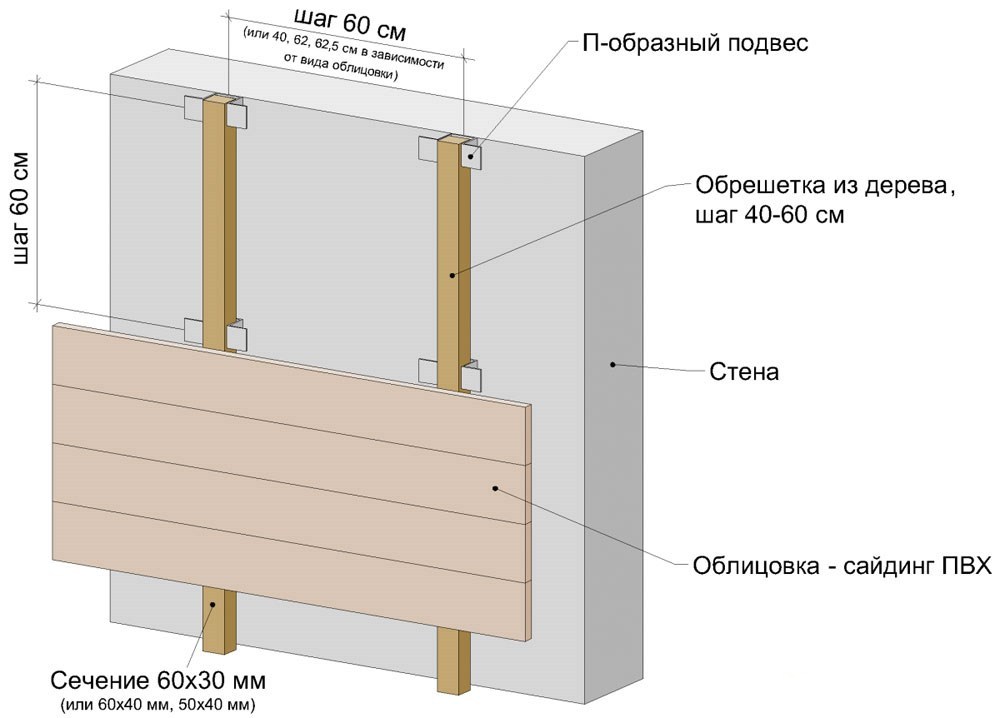

Then calculate installation frequency of vertical elements - usually 50-60 cm, and step between crossbars - by the height of the facade sheet. It is taken into account that at the external and internal corners of the building it is necessary to fasten the corner profile, and therefore provide for the installation of vertical profiles on both sides of the corner.

Calculate the expected load taking into account wind and rain and emit fastener pitch... The frame is placed on the brackets. In some cases, you will have to drill holes for them, so marking is required.

Fastening to a metal profile

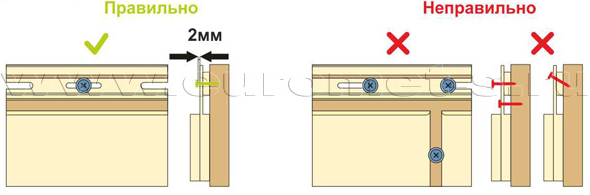

- For fixation take self-tapping screws with a rather large cap and a length of 16–20 mm. Galvanized is preferable: it is not much more expensive, but does not corrode and lasts longer.

- Self-tapping screws are screwed in exactly in the center of the oval hole for fastening. This slot is made so that when the panel is lengthened, it can slide along the mount. If you fasten the screw to the edge of the hole, the siding can no longer move and is damaged.

- The self-tapping screw is not tightened tightly... There should be a gap of 1–2 mm between the head and the cladding.

- Fastening is performed only after the panel is docked with the adjacent element and snapped into place.

Installation of panels on a wooden frame

Installation timber frame easier:

- from horizontal lintels only the lower one is required under the starting bar, and around windows and doors;

- you can install vertical elements on the wall and on brackets;

- better on edges and corners strengthen the structure metal profile - the load is higher here;

- you can only work in dry warm weather.

Fastening to a wooden crate is no different from installing to a metal frame. Use the same galvanized self-tapping screws and in the same way. However, staples and a stapler are allowed.

Installation nuances

At different temperatures, fasteners are made with different tolerances. If the siding is mounted vertically instead of horizontally, the docking rules change. Yes, and in the usual joint along the length there are tricks.

How to properly join PVC panels along the length

How to fix PVC panels indicated in the instructions.

- The panel is placed with its sharp end in the starting plate or in the groove of the element of the previous row.

- The locking blunt side is fixed relative to the lathing.

- Fix the position with self-tapping screws or dowels.

- The next element is inserted into the groove of the starting plate and into the groove on the side of the installed panel - until it clicks.

With this method, all joints are invisible.

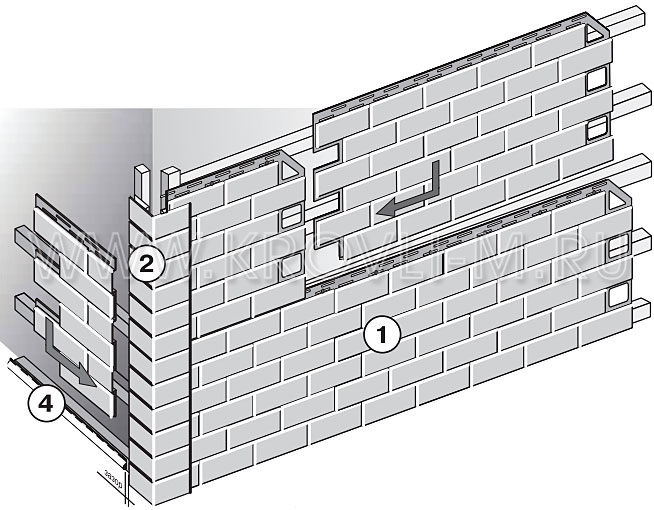

How to join panels in the corner

Complementary elements greatly simplify this operation.

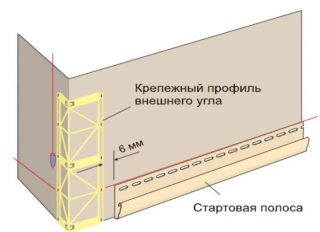

- Attached to a special corner corner piece... It is a complex profile with grooves for siding on both sides.

- It is allowed to replace the corner 2 J-barsinstalled joint to joint. The tightness of such a solution is lower, so there is a risk of leakage.

- A special profile is placed for the inner corner or j-trim bar... The element is fixed so that a gap of 6 mm remains between its lower end and the profile.

- When assembling, the panel is inserted with a cut flat edge into the corner profile and into the groove of the previous row or starting strip.

- The fastening is performed through the center of the matching oval holes on the profile and on the panel.

Groove thickness different elements for lamellas and panels. For cladding, you should buy elements based on their purpose.