For the construction of modern buildings, traditional materials (brick or stone) are used, as well as composite materials. This option provides standard wall strength and replaces vapor barrier, insulation and moisture protection. Installation of SIP panels instead of brickwork saves energy, time and money.

Advantages and disadvantages of the material

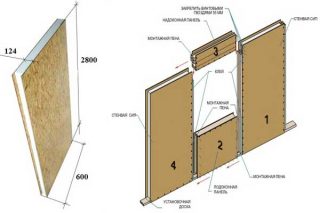

Panels relative small: width reaches 1.25 or 1.2 m, length - 2.5–2.8 m. The thickness is 11–20 cm. This is enough for the effect of heat preservation to be equal to a wall of silicate bricks 2 m thick.

SIP panels do not withstand heavy loads and by themselves cannot act as wall material. The finished load-bearing frame of the building is filled with such slabs.

The exterior of the frame buildings is not very attractive. The house needs finishing. It is advisable to choose an option that provides additional protection from rain and snow.

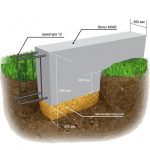

Foundation for a house made of SIP panels

The panel house is very light. This allows you to save on the construction of the foundation, which is usually 1/3 of the total cost of construction. From light foundations for such a building recommend choosing the following.

- Tape - reinforced concrete tape is laid around the perimeter of the house and under all load-bearing walls. The foundation deepens into the ground below the freezing level. The tape base prevents skewing or subsidence of the house. This is sufficient for a lightweight construction.

- Columnar - this option is used when constructing buildings in lowlands, in floodplain areas where the level of groundwater is too high. The foundation is made of brick or reinforced concrete posts, connected in the upper part by a grillage. The structure is designed for low weight, so it is quite suitable for a frame building.

- Pile - recommended for unstable soils. Iron piles are driven or screwed into the ground to the required depth. At the top, the piles are connected with a wooden base, which makes this option even cheaper.

It makes no sense to build a slab or monolithic foundation for a frame house. It is very expensive and massive, designed for heavy multi-storey buildings.

Step-by-step description of the construction of walls

During construction, Canadian technology is often used. In this case, the frame is erected entirely and immediately, and not in stages.

For the construction site, a well-dried wooden beam is taken. However, experts recommend using double planks instead of beams.

Instructions includes the following steps.

- A lower strapping is formed along the foundation.

- The longitudinal vertical posts are immediately strengthened, which rest on the foundation pillars. The corners are placed first.

- Then the frames of the window and door openings are fixed - both horizontal and vertical elements are fixed.

- The racks are connected with horizontal crossbars. The step depends on the total load on the wall and the thickness of the SIP panel.

- If necessary, the racks are reinforced with diagonal beams.

- Then you need to mount all the internal partitions.

Panel mounting

- You can start from any corner of the house... On the first panel, the side groove is filled with polyurethane foam, and then inserted so that the frame bar enters the groove.

- Check the verticality of the plate and fix it to the strapping bottom board with screws. Then the fasteners are made on each side and along the side edge in 15 cm increments.

- Then insert the panel from the second side of the corner.

- The slabs do not fit together. Each panel is inserted between the uprights... In this case, the grooves are filled with polyurethane foam.

This technology is used if the house is assembled from SIP panels as a whole, including the floor and ceiling. If Canadian technology is used, the frame is sheathed with plates.

External and internal finishing of the house with SIP panels

If OSB of 3 or 4 categories was used for the production of the material, in additional protection against moisture he doesn't need. But usually a less resistant OSB serves as a base, so it is better to protect a house made of panels.

The options are as follows:

- paints or varnishes - preference is given to waterproof compounds;

- oil impregnation with wax - emphasize the texture and color of the material, but need constant updating;

- siding - since the walls are still vapor-tight, any kind is suitable: wood, plastic, fiber-cement;

- sheathing with boards or clapboard - gives the house a beautiful look, but protects it from dampness poorly.

Interior decoration is also necessary. Chipboard, although it has an interesting texture, visually reduces space and gives the impression of bulkiness. Popular solutions:

- plaster - you can use any, but you should take into account the nature of the material itself. On a textured surface, Venetian plaster makes a strange impression;

- sheathing drywall - a much more popular solution, as it provides a flat, smooth surface;

- finishing panels - plastic, wooden.

The choice of finishing materials is limited only by their cost or weight. It is unreasonable to veneer a frame house with clinker.