The bearing capacity of the corrugated board means the ultimate load. The ability of the material to withstand various loads without deformation depends on this parameter. Depending on the purpose of the profiled sheet, products are produced with different corrugation heights, thicknesses and assembly widths. Additionally, the corrugated board is covered with anti-corrosion or polymer compounds. Full specifications are written in the labeling.

The area of use of the bearing corrugated board

The maximum permissible load on the profiled flooring significantly exceeds the load-bearing characteristics of a metal sheet of the same thickness. The higher the wave height, the better the material's ability to withstand loads.

The wall model C10-1200-0.6, installed on a support with a step of one meter, has a permissible load per square meter of 86 kg. The capacity of the bearing profiled sheet of grade НС44-1000-0.7, laid on the crate with a distance of 3.5 m, reaches the limit of 182 kg / m².

Scope of the bearing profiled sheet:

- Arrangement of roof coverings of any configuration and complexity, taking into account the pitch of the lathing from 3 meters.

- Installation of permanent formwork. In this case, the bearing profiled sheet for floors is able to withstand, without deformation, the weight of the concrete solution together with the frame. Thus, the corrugated board can perform a reinforcing function.

- Overlapping devices between floors, as well as for increasing the rigidity of structures with a supporting frame made of metal.

- As a heater for cold outdoor fences and buildings for various purposes.

The features of the profiled sheet allow the material to be used in industrial construction. The use of products helps to reduce the time for the construction of the facility and reduces costs.

The profile height affects the material's ability to withstand specific loads. The higher this parameter, the stronger the flooring. The value can be determined by the brand of the product.

Advantages and features of the profiled sheet

The advantages of bearing marks include the following factors:

- reliability with a low dead weight;

- affordable pricing policy;

- resistance to temperature changes;

- incombustibility;

- resistance to aggressive environmental conditions;

- galvanized and polymer layers increase service life;

- does not have a negative impact on the environment.

The fundamental difference between the bearing corrugated board and wall models is the greater rigidity of the first type due to the height. A feature is also the possibility of using the material in the construction of buildings and use as a roof covering.

Maximum permissible loads

Before purchasing material for a roof, construction or interfloor overlap, it is necessary to calculate the load on the profiled sheet. As a result of simple arithmetic calculations, it will turn out to choose the right brand of goods.

The bearing capacity of the profiled sheet in the load table allows you to understand the ability of the product to withstand various environmental influences:

Profiled sheet type | Span, m | Load based on support, kg / m2 | |||

| 2 | 3 | 4 | 5 | ||

| HC35-1000-0.55 | 1,5 | 432 | 247 | 282 | 271 |

| HC35-1000-0.7 | 3 | 68 | 172 | 133 | 142 |

| H57-750-0.7 | 4 | 91 | 170 | 199 | 190 |

| H57-750-0.8 | 3 | 337 | 365 | 426 | 409 |

H60-845-0.7 | 323 | 230 | 269 | 257 | |

| 4 | 122 | 203 | 254 | 241 | |

| H60-845-0.9 | 3 | 439 | 427 | 504 | 482 |

H75-750-0.8 | 582 | 527 | 659 | 615 | |

| 4 | 248 | 296 | 370 | 345 | |

H75-750-0.9 | 3 | 645 | 617 | 771 | 720 |

| 4 | 293 | 347 | 434 | 405 | |

| H114-600-0.8 | 6 | 193 | 261 | – | – |

H114-600-0.9 | 4 | 659 | 659 | 824 | – |

| 6 | 218 | 293 | – | – | |

H114-600-1.0 | 4 | 733 | 733 | 916 | – |

| 6 | 244 | 325 | – | – | |

When calculating corrugated board for loads, it is recommended to rely on the installation width. Otherwise, when using materials for other than their intended purpose, a shortage of sheets will be revealed.

Calculation of the load and criteria for choosing a profiled sheet

First of all, you should take the initial information:

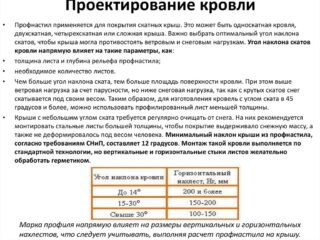

- a house with a gable roof and an angle of inclination of 40 °;

- the slope on the horizontal plane is 65 °;

- the construction of the building is planned in the Moscow region.

Determination of the magnitude of the load on the material as a roof covering is obtained by adding the weight of the product, snow and wind effects. The first parameter depends on the size of the installation overlap, which is 8.6 kg / m².

Snow load depends on the region where the construction is located. The Moscow region was assigned the 3rd coefficient, which is 180 kg / m². Taking into account the slope of the roof of the structure, the calculation is as follows: 180 x (65 ° -40 °) /) 65 ° -25 °) = 112.5 kg / m².

The wind load is also tied to the region - in this case, the region is assigned 1 coefficient equal to 32 kg / m². Taking into account the slope of the gable roof, the parameter of the aerodynamic resistance of the corrugated board will be ~ 0.3. The wind load is defined as 32 x 0.3 = 9.6 kg / m².

Thus, the calculation of the profiled sheet for deflection in this case will look like: 8.6 + 112.5 + 9.6 = 130.7 kg / m². Having consulted the table of loads, it was revealed that grade H114-600-0.8 is suitable for a gable roof.

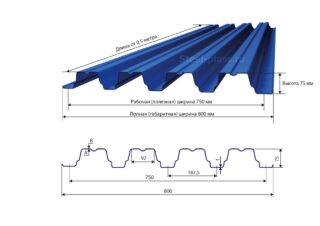

The width of the profiled material is divided into overall and mounting. The first option indicates the general parameters of the product. The second parameter assumes a reduction in size due to the installation of fasteners to connect the sheets to each other.

Types of corrugated board

Bearing grades of corrugated board are used for interfloor floors, roofs, as well as in construction. This material is made from metal. It is marked with the symbols "H" and "C". For manufacturing, galvanized steel with or without coating is used on special equipment. During the production process, the steel is subjected to mechanical stress, due to which a corrugation is formed. The height of the slope is different - this indicator determines the strength characteristics of the finished product.

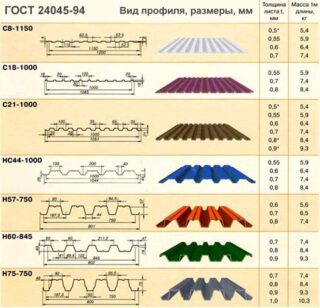

The bearing type of corrugated board is produced in accordance with GOST 24045-2016.

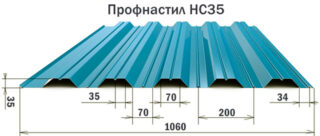

NS-35

Main area of application:

- construction of fences;

- erection of panel structures;

- auxiliary elements of floors;

- fixed formwork;

- construction of load-bearing structures;

- construction of change houses;

- decorative wall decoration.

NS-25 is produced from galvanized sheet steel with a thickness of 0.45-0.70 mm. A polymer coating is applied to the surface. May be used on unloaded arched roofs.

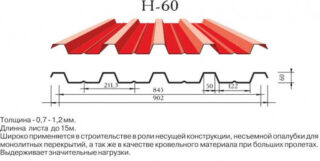

N-60

The load-bearing capacity of the product can be increased by using auxiliary profiling, which will serve as additional stiffeners. For these purposes, a small gutter is also installed. The technology improves the strength of the sheets.

Profiled sheet H-60 is used as a material for the roof. This is due to the resistance to heavy winds and snow loads.It is allowed to use for the construction of technical rooms, change houses, as well as a permanent perimeter fence. Often this brand is used as sheet reinforcement and in the construction of pre-fabricated buildings.

The corrugated board with an aluzinc coating is marked with the “AC” symbol.

N-75

The thickness of the product is 0.45-0.9 mm. The surface is additionally treated with a polymer composition to increase the protective functions and give the surface a decorative value. The corrugated board of this brand is resistant to deformation, storm winds and snow load. This is due to the rolled grooves on top of the shelves. The use of this technology creates additional rigidity, increasing the strength of the product.

The technical parameters of the H-75 make it possible to use the material in any areas of construction - from roofing, to the construction of industrial and commercial structures. The products are also used for frame structures, as permanent formwork and sheet reinforcement.