The walls of a wooden house darken over time and take on an unattractive look. Gaps appear between the bars or logs; due to drafts and blowing, the comfort of living is reduced. Brick-lined houses that look beautiful, have additional insulation and wind protection. Before covering, the weight of the new layer is calculated and the foundation is checked for bearing capacity.

The need for lining

The reasons, according to which a decision is made on the brick lining of the house:

- necessity is essential insulate the building, reduce heating costs;

- improvement appearance building;

- increase service life withtary wooden walls.

The existing timber walls are crumbling, the influence of wind, frost, insolation leads to the fact that the house looks like a dark, inexpressive spot. New log cabins veneered rarely, but if such a decision is made, wait a couple of yearsso that the log structure shrinks.

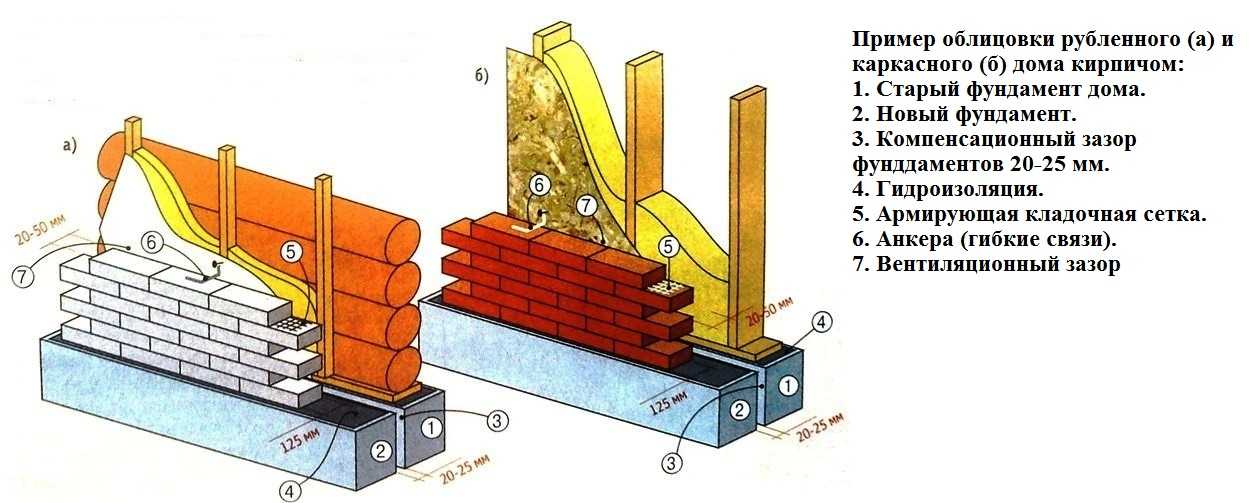

The choice in favor of brick cladding decides and foundation condition... The base should be wide enough to support the brickwork. Otherwise, the expansion of the existing foundation will be required. To do this, a trench is dug near the base and an additional concrete strip is poured. Metal reinforcement rods are driven into the existing foundation every 0.5 - 0.7 m in a checkerboard pattern to tie the two bearing foundations together. This technique will additionally unload the old foundation if its parameters do not correspond to the norm.

If you overlay a wooden house with a brick, it will become warmer, since between the brick layer and the old wall of timber lay insulation... This can be mineral, stone or glass wool, polystyrene, expanded polystyrene. It becomes possible to lay a vapor barrier and waterproofing protection, as well as a film against the wind.

Varieties of facing bricks

Most often used ceramic brick... It is the most expensive decoration stone. The material has good technical performance: frost resistance, strength, durability, moisture resistance.

Other types of facing stones:

- Non-fired or hyper-pressed. The brick has a decorative appearance due to the corrugated and torn surface on the front side.Pigmentation increases attractiveness, but this variety absorbs water.

- Clinker. The material is highly durable, resistant to moisture, chemistry, frost. Requires the use of a hard mortar so that the masonry does not move.

- Silicate. Inexpensive lining, short-lived, absorbs moisture, therefore such material is not used for facing the basement, but only placed on the walls.

The order of work

Expand the foundation if necessary so that it serves as a support for a brick wall, which is moved away from the wooden one, taking into account the ventilated gap and the layer of heat insulator. For polystyrene, polyurethane foam, polystyrene foam, a ventilation gap is not required, since the material does not absorb liquid. It is better to use mineral wool to ensure the "breathing" of the inner wall.

When covering, take into account the moments:

- wood and brick have different characteristics, so you cannot put rigid reinforcement or mesh for the bundle;

- if the old walls are thick enough, insulation is not used, but wind protection and vapor barrier are required;

- the ventilation gap is made with an exit under the roof (holes at the rate of 75 cm² for every 20 m² of the vertical fence), and in the first row of masonry air vents are made for the entrance of air flows.

To create a product use the techniques of laying hollow stone with holes outward, partial filling of the joints between bricks.

Step by step process

The surface of the log house is cleaned from protruding nails, hairpins. At this time, be sure surface treatment insect repellents and against fungus, use fire retardants against fire.

Further order:

- stuffed on a wooden wall vapor barrier membraneby correctly defining the front side;

- do crate from a wooden plank with a thickness of 6 cm to obtain a gap of the same size;

- stuffed onto the frame mineral wool insulation, it is fixed with dowels with wide caps;

- stuffed on the insulation windproof film, you can use polyethylene, but it is better to put a professional vapor-permeable material;

- mark the masonry line so that there is a gap of 3-4 cm between the insulation and the brick for the passage of air;

- masonry is carried out in half a brick for one-story and two-story houses;

- horizontal and vertical check the building level;

- between the vents there should not be a step more than 4 meters, the holes are protected with a fine mesh from rodents.

For the lathing, you can take galvanized profile... If a rail is used, I process it with linseed oil for 2 times.

Features of masonry reinforcement

In one reinforced layer, apply 1 - 2 rods (depends on the quality and type of brick). Metal rods with a grooved surface are better suited. The armature is completely immersed in the mortar on which the brick is placed.

Binding to the wooden wall do every 4 rows of masonry. Steel wire 6 mm thick is used, a part is made of it with a loop at one end (in masonry). And it is tied to a wooden wall with a self-tapping screw, nailed with a bracket or a hairpin.