Decorating the premises with PVC panels is a practical and affordable option. The material is available in a variety of types. It is distinguished by its high resistance to moisture and steam, therefore it is readily used for cladding baths and kitchens. Installation of PVC panels is carried out on a crate made of metal strips.

Metal profile frame for PVC panels

Plastic trim can be fixed in 2 ways... With good evenness of the walls, the panels are glued or fixed with self-tapping screws. directly onto the base surface. This method is not welcome, since there is no technical gap for air circulation between the wall and the cladding. Therefore, for example, in the bathroom, it is fraught with condensation or mold. In a dry room - a corridor, a bedroom, this does not happen.

A more versatile method is installation on a frame... The frame structure creates an air cavity under the trim, which ensures moisture evaporation and no condensation. In addition, the lathing allows compensate for any unevenness in the wall.

For the frame take wooden beams or steel slats.

How much material is needed

To make a crate for plastic panels in a kitchen or bathroom, you need calculate the number of profiles, brackets, fasteners and other additional elements. The calculations are simple.

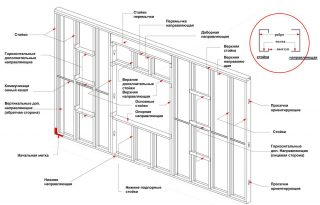

The finished crate is a plane formed by vertical and horizontal elements. The distance from the outer side of the rail to which the panel will be attached to the wall is provided by the bracket.

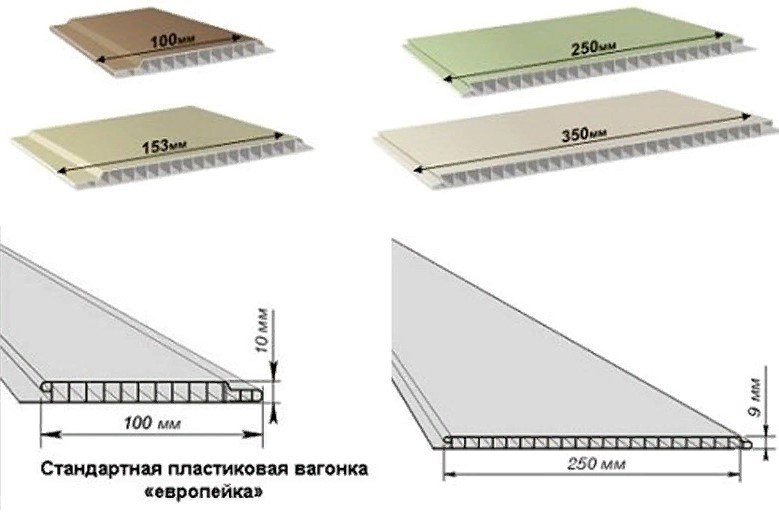

The determining parameter for the calculation is the panel size, which means the location of the horizontal elements to which the trim is attached. For the wall, the distance between the posts is 45-60 cm, for the ceiling - 35-40 cm.

- Determine the height and length of the wall to find the length of the profile.

- Divide the height by the required installation step. One more bar is added to the total.

- Hardware is required to secure the rail. Typically, a 1.5 m strip requires 2 to 3 fasteners. The length of the rail is divided by the step of installing the fasteners and multiplied by the number of horizontal elements.

- Calculate the number and length of the guide profile into which the carrier is installed. This is a vertical rack slightly less than the height of the room. The minimum number of posts is the same as the number of corners. For long wall lengths, intermediate uprights will be required.

- Take into account window and door openings. They should be framed with a metal profile frame.

It is recommended to increase the overall profile length by 5% to account for possible errors or the need for additional reinforcement.

Carrying out marking and installation work

It is rather difficult to mount a metal frame for PVC panels. The work requires accuracy and precision.

- Check the parallelism of the floor and ceiling. If the planes are not parallel, determine the level of installation of the frame. To do this, in the corner where the ceiling height is the lowest, mark the lower and upper points. Often, the corner profile is installed immediately.

- From the bottom point laser level lay the point in other corners of the room and connect with a marker.

- Do the same with the upper point. The guide profile is fixed at the corners.

- It is advisable to make horizontal marks on the walls where each rail will be fixed. If you need to drill holes for fasteners, the installation locations of each bracket are marked on the wall.

- Analyze the plane of the wall. Places where there are depressions, depressions, height differences should be noted.

- Install around window and doorways profile slats. This is a required item. With a large wall area, intermediate vertical racks are mounted.

- To respect the plane of the frame, tie the corner profiles with a cord and set all horizontal elements according to its level. If the height differences are large, then the frame is fixed on special brackets that allow you to adjust the distance between the wall and the profile.

Do-it-yourself ceiling mounting is performed according to the same algorithm. Instead of brackets, suspensions are used.

Features of different materials for frames

For lathing for PVC panels in the bathroom, use galvanized profile, wood and plastic guides.

The popularity of the rather difficult installation metal frame due to the durability and the ability to vary the design of the lathing within a very wide range. If a metal frame is installed, the initial state of the wall or ceiling does not matter.

Wooden lathing is much cheaper. But the tree is poorly resistant to moisture. The material in the bathroom is treated with antiseptics and water repellents. In some cases, this is sufficient. Another problem with wood is insect decay. The timber should be treated with an antiseptic. However, it should be remembered that impregnations provide safe operation only for a certain period.

Plastic crate Is a fairly new option on the market. Guides are made of plastic, like a metal profile, but lighter. They are fastened with screws or nails. The material is not afraid of water, does not corrode, and is strong enough to support the weight of the panels.

The trim is fixed to the plastic guides for kleimers. This is a little more complicated than fastening with screws, but it provides another advantage: the clips do not damage the panels, after dismantling they can be reused.