On sections of walls with an increased danger of fire, according to building codes, it is necessary to install materials that are resistant to flame and high temperatures. Fire-resistant gypsum board is successfully used as finishing of fire hazardous places. They are faced with partitions with laid electrical wires, places near fireplaces, partitions in saunas, baths, and in industrial construction - the walls of production units and boiler rooms.

Description of fireproof drywall

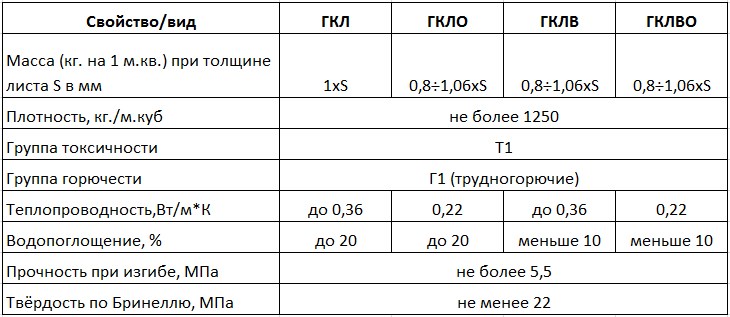

Density of material more than that of standard drywall sheets and is 850 kg / m³. Fire-resistant gypsum plasterboard conducts less thermal energy, its thermal conductivity coefficient is 0.22 W / (m K), and for a simple one - 0.35 W / (m K).

Other characteristics heat-resistant drywall:

- flammability group does not exceed G1;

- smoke production index - D1 (forms a small volume of smoke);

- the ability to ignite - B1 - B2;

- toxicity category - T1 (no toxic components are released when heated to high temperatures).

The side edges of the sheets are finished with construction cardboard, as are the working planes. Material impregnated with fire retardant, and the edges are always made semicircular thinned, in order to reliably putty the joint during subsequent finishing.

Sheets with a length of 1.5 - 3.0 m, a width of 1.2 - 1.5 m are produced with a thickness of 12.5 or 15 mm.

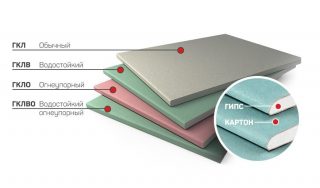

Panels only non-combustible plasterboard painted in gray or deep pink color, in shade closer to red drywall. If a panels additionally resist moisture, their color is green.

Fire protection structure

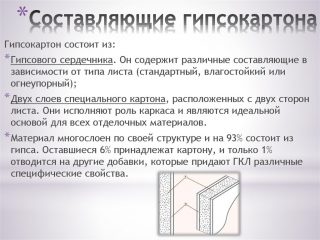

The composition of the gypsum core during manufacture include components:

- two layers of a soft mineral in the form of gypsum dihydrate;

- fibers in the form of glass filaments that do not break or break, while bending without breaking;

- fire-resistant substances in the form of an additional clay layer;

- crystallized water.

The plaster mass is poured into prepared cardboard. Non-combustible drywall is finished on both sides with cardboard casings, which impregnated with fire retardants - substances that increase the resistance to ignition.

Advantages of heat resistant drywall

The value of the cladding is in the fire resistance of the GKLO, therefore, experts recommend that the interior decoration of the house be made with just such sheets in case of fire. The material will attenuate the flame and will not degrade within 25 minutes. Conventional gypsum boards are capable of holding back fire for only a few minutes due to a non-combustible gypsum core.

Like ordinary panels, sheets of pink drywall are used to create an original interior. The ceilings of such plates will be intact for some time when heated. They will not fall, they will not injure a person who can leave the premises during this period of time.

Varieties of fire-resistant drywall

GKLO Are slabs that do not resist moisture, but only restrain the fire in case of ignition and fire. In the composition of their core there are no hydrophobic additives that could increase the resistance to water soaking. The color of these sheets is gray, but the markings on the fire-resistant drywall on the back are red.

There are plates refractory GVL, but this material differs from the usual drywall in that there are no cardboard shells in its structure, the sheets are homogeneous panels.

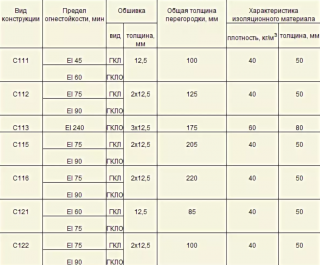

Fire resistance

In accordance with construction standards, the fire resistance of the gypsum board is marked with Latin letters and numbers. The last signs testify about the degree of fire resistance of drywall - show time interval in minutes, during which the panels are not destroyed by the action of open fire.

The letters indicate the state of the slab fire resistance:

- E - loss of integrity - the appearance of cracks and holes through which smoke and flames enter the room without igniting;

- I - loss of thermal insulation protection by the fence due to the action of fire;

- R - loss of bearing capacity, deformation, destruction.

Flammability test procedure

Testing procedure:

- take 3 sheets of gypsum plasterboard from a test batch of goods;

- the flame of two gas burners is directed to the sample;

- the fire test is carried out for 20 minutes, so that the surface temperature reaches + 800 ° C;

- all samples are tested.

Application and installation features

They are used for cladding walls of evacuation corridors, tunnels, in the form of passive insulation from fire of building structures, structures. For example, in a wooden house, cladding significantly increases the fire safety of the building. There are no restrictions on the use of fire-resistant drywall sheetsbecause the material is environmentally friendly.

- metal profiles are used as a frame;

- fasten the sheets with hardware with appropriate fire-resistant characteristics;

- when lining communication shafts and shafts, additional insulation is made from fire-resistant materials, for example, a foil layer or mineral wool;

- the outer corners are trimmed with metal corners, which increase the strength of the entire structure.

The panels are installed so that they get between the edges clearance of 1 - 2 mm, self-tapping screws are placed with a pitch of 200 - 300 mm. Pay attention sealing of seams, for work use special compositions with modifiers that give heat resistance to the putty. Apply brands "Osnovit Shovsilk PG 33 H" or "Volma-seam".