Profiled sheet is a fairly popular material used for roofing in the construction of fences or metal boxes. This popularity has led to the choice of a more varied material design. Today you can find profiled sheets for brick, wild stone, wood and other materials.

Features and advantages of the material

The basis of the profiled sheet is a galvanized iron sheet. It is very thin - from 0.4 to 1.2 mm thick, lightweight and usually has some relief. Typically, the drawing is very simple and designed to facilitate the drainage of water and snow from the roof. However, relief can be used in a different way.

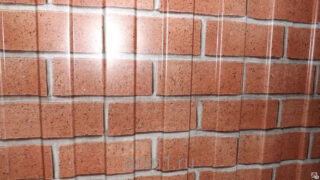

The profiled sheet with a brick pattern imitates stone cladding. The effect is created by combining the appropriate relief pattern and color. For coloring, formulations are chosen that are durable, resistant to ultraviolet radiation and temperature.

Decking "brick" has the following advantages.

- Coloring is carried out only with compounds of increased strength and wear resistance. Particular attention is paid to resistance to sunlight. Such a coating does not fade even in southern latitudes at an altitude of 500 m above sea level.

- To get a relief pattern, the polymer coating is laid in a thick layer. And this increases the wear resistance of the material.

- The polymer coating protects the steel base from corrosion and has a water-repellent effect.

- Only paint is used to create a smooth surface. This feature makes it easier for water to drain off. In addition, smooth flooring is much easier to clean: it is enough to douse the fence or facade with water from a hose.

- The sheets have a minimum weight of 5–6 kg. Such a roof or facade decoration does not constitute a large load and does not require reinforcement of the foundation.

- The lightness and strength of the corrugated board makes installation much easier.

It is difficult to find the disadvantages of a decorative profiled sheet, except perhaps a slightly higher cost compared to the usual one-colored one. It should also be borne in mind that the mechanical strength of such a cladding is much lower than a real brick one.

How to make a professional sheet

The scheme for the production of corrugated board with a brick pattern is quite simple. This is a kind of rolled metal that can be produced by both large factories and small private companies.

The basis is a cold-rolled steel sheet with a thickness of 0.1 to 1 mm. This is a GOST requirement. The billet is transferred during rolling to the corresponding machines, where the sheet is bent at the required angle and gives it a certain relief. Most often wavy or trapezoidal. The height of the ridge and the thickness of the sheet determines the purpose of the material:

- wall - for finishing the facades of houses with rib heights from 6 to 20 mm;

- intake - has a ribbed or wavy surface with a ridge height from 20 to 44 mm;

- roofing - less rigid with a rib height from 44 to 57 mm;

- bearing - the most durable, with a wave height of 57 mm.

There is a corrugated board used for interior decoration with a rib height of 2.5 mm, however, this option can also be used for finishing the facade.

The profiling of the sheet is only the first stage of production. Then the workpiece is immersed in a bath and covered entirely with a layer of zinc. The thickness of the layer depends on the purpose of the material.If the profiled sheet will be used in regions with high humidity or near the sea, the zinc layer here should be at least 25 microns. In milder conditions, the zinc layer can be thinner.

At the last stage, the corrugated board is covered with polymer paint. The pural-based mixture remains the most persistent. It also allows you to apply a decorative brick-colored coating to the corrugated board and create a micro-relief.

Manufacturing materials

The following materials are used as a blank:

- black steel without polymer coating;

- galvanized steel is much more reliable, since the zinc layer protects the alloy from corrosion;

- chrome-nickel steel - stainless, such a flooring does not need a protective layer;

- copper - does not corrode due to its physical properties, attracts with a beautiful color and shine;

- aluminum alloys - due to passivation, they are covered with an oxidizing film and do not rust.

The material affects the purpose of the profiled sheet. Aluminum is recommended for roofing. The material is lightweight, easy to lay and strong enough to withstand hefty wind and snow loads. Copper is more often used in the construction of internal partitions, since the material is very beautiful, expensive and plastic.

Where is the professional sheet for brick used?

Decking under a brick finds a wide variety of applications. But since its distinctive feature is precisely the similarity with building material, it finds an appropriate application.

- Decking for a brick is used for a fence. Stone fences are not uncommon: they look solid, very strong and durable, but roads take a long time to build. Using a galvanized sheet of iron, you can build a fence much faster. And the imitation of stone allows you to give the fence a similarity to brick.

- The material is also taken for roofing. The strict hermetic pattern creates a very unusual aesthetic effect. In this case, it is important to choose the shade of the profiled sheet.

- Plinth finishing is a classic application of a profiled sheet under a white brick. The cladding is almost permanent if it is made of aluminum or stainless steel.

- Facade cladding - if the profiled sheet plays the role of metal siding or panels. Plus: sheathing is much faster, since the sheet size is much larger.

- Room decor - modern designers began to use corrugated board in the design of office workspaces. High thermal conductivity, compensated by the correct insulation of the walls.

- A garage, a shed, and another household object can be entirely built from a bearing profiled sheet, decorated with a brick. The construction turns out to be easy, it is erected very quickly, but at the same time it is durable and reliable.

A professional sheet imitating brick is an unusual design option for the material. It is used both "for its intended purpose" - for roofing, and in those cases when they want to achieve similarity with brick structures.