A universal profile with a wave of 8 mm is used in the construction industry for the installation of enclosing structures. The ability of the working surface of the C8 profiled sheet to withstand heavy loads is reduced to zero. On roofs, it is used if the slope of the slope exceeds 40 °, in other cases, the material goes to suspended ceilings, facade cladding and fences.

- Description of corrugated board brand C-8

- Production technology and painting

- Colors of the profiled flooring С-8

- Advantages of the material, unlike the S-20 corrugated board

- Specifications

- Classification by type of coverage

- Application area

- Decoding of marking

- Manufacturing requirements

- Steel thickness for the production of C-8 profiled sheet

- Differences between sheets with and without polymer coating

- Installation technology

Description of corrugated board brand C-8

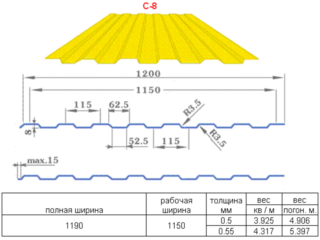

On the surface of the products, there are trapezoidal waves that protrude 8 mm above the surface. The distance between the corrugations is made 52.5 mm. Modern technology makes it possible to produce strips of material from 0.5 to 12 meters long.

The performance is influenced by the parameters:

- base metal thickness;

- zinc film thickness;

- the type of polymer used and its thickness.

The weight of the C8 profiled sheet and the working size allow it to be classified as wall and facing materials. Products represent a metal base with protective films made of zinc and polymers. The corrugated surface provides additional hardness and strength.

The sheets are fixed to the girders with self-tapping screws with a diameter of 4.5 - 6.5 mm with a galvanized layer on the surface. In mildly aggressive operating conditions, self-tapping screws with a length of no more than 100 mm, made of corrosion-resistant steel, are installed. On the roof, sealing gaskets are used under the heads of the roofing hardware.

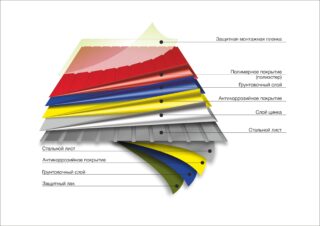

Production technology and painting

The metal profile is made of rolled metal, which already has a paint-and-lacquer coating on the surface. The production requires high-quality stamping equipment, since the thin layer can be damaged during the bending process. Finished stamped products are rarely painted, since the corrugated surface is more difficult to process.

The complete production cycle includes processes:

- galvanizing on both sides of ferrous metal sheet to increase corrosion resistance;

- passivation (obtaining an oxide film) to reduce the chemical activity of zinc;

- application of a primer to improve adhesion;

- polymer coloring;

- processing with additional protective compounds.

The polymer coating is made with a thickness of 25-200 microns, in more massive layers a relief embossing is punched in the form of a pattern of wood fibers, stone elements. The paint is applied by rolling on automatic conveyors.

Colors of the profiled flooring С-8

C8 corrugated board is painted in accordance with the RAL catalog, which unifies the colors of different products. Shades and basic colors are designated using four numbers, all colors are included in the catalog list.

The labeling of the sheets has at the end a combination of letters that indicate the type of protective coating:

- AC - zinc-alumina layer;

- PVC - polyvinyl chloride, plastisol;

- PUR - polyurethane film;

- EOCP - zinc with an oxide film;

- PE - polyester;

- AK - acrylic protection;

- PVDF - PVDF (Polyvinyl Dentofluoride).

The material is produced with double-sided or one-sided painting. This characteristic is also reflected in the letter designation: A - color on one side, B - on two.Color standardization and coating uniformity make it easier for suppliers, builders and property owners to make choices. This is important when buying additional elements, ordering additional material

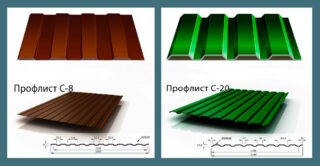

Advantages of the material, unlike the S-20 corrugated board

For wall cladding, great strength and rigidity are not required, therefore the dimensions of the C-8 profiled sheet and technical characteristics are suitable for such an application.

Positive properties of C-8:

- polymer and zinc layer protects against corrosion;

- lightweight material does not load the facade, supporting structures, the elements are mounted simply and without the use of lifting mechanisms;

- the working width of the C8 profiled sheet is not too different from the general one, so the area can be covered more economically than with C-20 profiled sheets;

- it is possible to order the required size in length to make the plane of the walls without seams, to speed up the finishing process;

- a large assortment of colors and shades, varieties of polymer coating, you can choose an expensive and budget option.

The S-20 brand is placed on roofs and loaded structures, while the dimensions of the waves of the C-8 corrugated board can be used for the facade.

Sheets C-8 are classified as "economy class", since the small height of the corrugation saves material. The products are installed with an overlap of one wave, therefore the useful width of the C8 corrugated board or the working width of the sheet differs from the C-20 products. There are no stiffening ribs on the crest of the corrugations and between them, and there are no capillary grooves either.

Specifications

Gofrolist refers to composite materials that have a continuous heterogeneous structure. Clearly delineated layers work together, therefore they give additional useful qualities to the metal at the base of the corrugated board.

Characteristics of the facing layer:

- resistant coating does not react to chemically aggressive components of the atmosphere;

- the professional sheet is reliable, it is used for a long time;

- after installation and in the process of work, complex care and painting are not required;

- does not collapse from moisture, ultraviolet radiation, temperature extremes;

- the material weighs 4.1 - 5.59 kg / m²;

- useful product size in width - 1150 mm;

- the width of the projection at the top is 62.5 mm.

If the S-8 professional sheet is used for awnings, you need to take into account the sound of the material, its ability to transmit sounds. They get rid of the effect by arranging soundproofing layers. They cut the corrugated board only with hacksaws or circular saws, since the usual grinder destroys the protection at the cut.

Classification by type of coverage

For grade C-8, the following types of coatings are used:

- Acrylic. Includes synthetic fibers, acrylic particles mixed with methacrylic acid. The coating does not deteriorate for a long time, but the area fades after 3 - 4 years. The polymers on the surface are 25 µm thick.

- Polyester. The second budget type of coating, but retains its resistance to sunlight longer (about 20 years). The material is mounted and transported carefully so as not to damage the 25 micron film.

- Plastisol. The composition contains modifiers and polyvinyl chloride fibers. Thick film (200 microns) is durable, it is embossed on it to match the relief of natural materials.

- Pural. Polyamide particles are mixed with polyurethane, as a result the coating (50 microns) is reliable and durable. It can be used in aggressive operating conditions, the layer does not fade and does not collapse for about 50 years.

The best quality of all is considered a film of polydifluorionate, which reliably protects the metal from mechanical and chemical action. She works steadily on the seashore, where there is increased insolation, and along highways with harmful emissions.

Application area

The height of the corrugation is a characteristic that indicates the strength characteristics of the product. Standard wave sizes of C8 profiled sheet do not make it possible to put it as loaded elements.

Material Application Cases:

- Cladding of walls of houses, industrial workshops, cladding of facades of public buildings, social facilities. Sheets are placed as a wall fence in the construction of pavilions, exhibition halls, sports grounds.

- Sandwich panel production. Sheets C-8 are used as part of such plates together with insulation and waterproofing membranes.

- Filling the space between the elements of the skeleton of frame structures. The plane of the sheet does not withstand strong winds, so transverse jumpers are installed.

Roofs are also covered with sheets marked C-8, but there must be a large slope so that snow does not accumulate in the area. In another case, they are placed in the southern regions, where the snowfall is minimal.

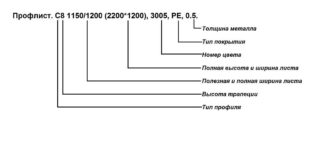

Decoding of marking

Numbers and letters are applied on the package label. Information includes information about the manufacturer and its trademark. The alphanumeric designation of the material, the number of products in a pack, and their length are prescribed. Indicate the weight of the package with the profiled sheet, apply a stamp on technical inspection at the factory.

Letter C means that the material is intended for wall decoration, in addition there are letters for other types of corrugated board:

- H - bearing corrugated sheet, used for loaded roofs;

- NK - used in the structure of reinforced concrete floors, non-removable formwork elements;

- NK - for roofs;

- NS - a universal option for fences, fences, roofs at the same time.

The number after the first letter shows the height of the wave in millimeters, the second - the thickness of the sheet. The third number indicates the useful width of the material, the last one indicates the length of the strip.

Manufacturing requirements

Some manufacturers use GOSTs in production, others use independently developed technical conditions. The latest standards are also based on state standards with minor deviations.

GOSTs are used:

- GOST 24.045 - 1994, TU 11.22 - 079 - 024.946 where requirements for methods of cold rolling of thin sheet metal are indicated;

- GOST 9.401 - 1991 on standards for the paintwork system and requirements for test procedures;

- GOST 75.66 - 1994 includes a decoding of the conditions for the acceptance, packing and transportation of metal sheets;

- GOST 14.918 - 1980 on the requirements for the condition of thin sheet steel after passing a continuous conveyor.

The set of equipment for production should include a steel coil decoiler, a mechanical rolling conveyor, a guillotine (shears), a receiving device, an oil station, an automatic control station.

Steel thickness for the production of C-8 profiled sheet

Cold-rolled steel (GOST 52.246 - 2004) with a galvanized layer is taken in the form of raw materials. Steel with a paint or polymer film must comply with GOST R 52.246-2003.

For production, choose metal with a thickness of 0.4 - 0.7 mm. In the case of determining the thickness, galvanized film and polymer layers are not taken into account, since they are measured in microns, which does not affect the overall size.

Cases of using corrugated board of different parameters:

- metal 0.4 - 0.45 mm is placed for the walls of temporary structures, arrangement of internal functional partitions;

- sheets of 0.45 - 0.55 mm are taken for fences, fences, external barriers;

- strips up to 0.7 mm thick are mounted on facades, especially of industrial buildings.

Thickness deviations are regulated by GOST 19.904 - 1990, where it is indicated that a thickening of 0.06 mm in one direction or another from the norm is allowed.

Differences between sheets with and without polymer coating

These two species have different appearances.Only galvanized material is distinguished by a gray color with a gloss that fades after the first year of service. Polymer coatings will make it possible to produce white C8 profiled sheet, green, red, blue, chocolate, while increasing the attractiveness of the fence or the walls of the building.

Difference in service life:

- a simple coating without polymers will last about 20 years;

- an aluzinc layer on the surface will extend the operating time up to 25 years;

- the material with paint and varnish protection will last longer - up to 50 years.

The decision to purchase sheets with or without protection is made by the user, depending on the purpose of the building, the time of the intended operation, material capabilities.

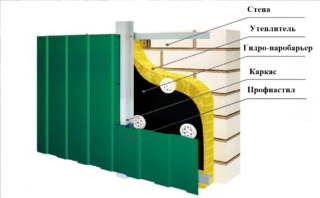

Installation technology

Before installing the sheets on the facade or fence, make a drawing with size markings.

The technology of fixing the corrugated board to the walls and as a fence is different:

- Facade. They make a crate in the form of a frame made of slats. Insulation is inserted inside, insulating membranes from steam, moisture, wind. For the device of the layer, additional strips, inner and outer corners, start, finish and others are used.

- The corrugated board on the fence posts is attached directly to the posts. Sometimes special cards are welded from a metal corner, in which strips of profiled metal are fixed. Such frames are mounted to the supports.

- If the S-8 profiled sheet is placed on the roof, it is better to make a continuous crate from chipboard, OSB panels. Otherwise, a lathing of slats with a gap of no more than 10 mm will do.

On the facades, I combine different colors of the material to improve the aesthetic appearance. The connecting strips are pre-installed on the border of the colors. Window and door openings are decorated with special J-strips.

When installing fences, the racks are installed in the corners of the land plot, and on extended sections they are placed every 2.0 - 2.5 meters. If the fence is on a slope, then the racks are placed taking into account the slope of the terrain.