OSB board is a multilayer sheet of flat pressed shavings glued together with synthetic resins. The material has found application in many areas of construction, especially in frame technology. The woodworking product is a competitor to chipboard (particle board). In terms of strength and durability, it is confidently ahead of the usual materials. The variety of OSB assortment requires studying the characteristics of each type of product in order to choose an option designed for future load and operating conditions.

- What is OSB plate

- Varieties of oriented strand board

- Sheet Specifications

- Standard sheet sizes

- The use of OSB boards in construction

- Sheathing of frame structures

- Manufacturing of SIP panels

- Subfloor and attic flooring

- Installation of roof lathing

- Internal and external wall decoration

- Creation of removable formwork

What is OSB plate

In stores, products are also found with OSB marking... The product owes its appearance Canadian scientistswho were looking for an efficient way waste disposal woodworking industry. After several improvements, a modern version appeared. OSB oriented strand board.

Sheets are made mainly from coniferous wood chips... Her length 5-18 cm, thickness 0.5-0.9 mm.

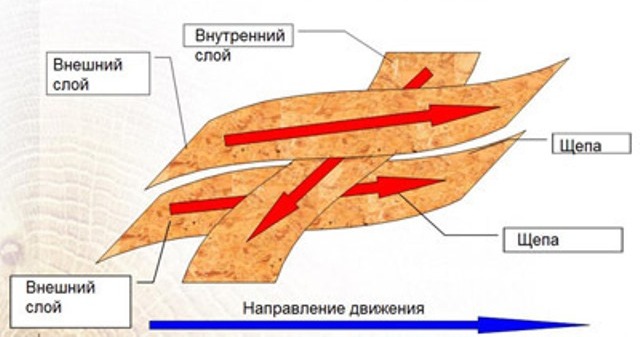

The feature of the material is different spatial orientation of the chips... In the outer layers, it is located along the axis of the slab, and in the inner layers - perpendicular to it.

After polymerization, the binder resins and wax provide strength to the sheet structure. This design makes the products sustainable, able to accept high load. Adding to the composition boric acid increases the ability to resist mold... Average sheet density 660 kg / m³.

OSB panels are used at all stages of building construction: from installation formwork to device roofs... They are used in the manufacture of furniture, packaging, billboards.

The main manufacturers of quality products are companies from Europe, the USA and Canada. The brands Norbord, Egger, Kronoplay, Glunz are recommended. Chinese products are cheaper, but often have higher resin values. Products of Russian factories are noticeably inferior in strength to foreign counterparts, but the budget price attracts buyers.

Varieties of oriented strand board

- OSB-1 - panels are designed for non-loadable structures and low humidity operation.

- OSB-2 - sheets have high mechanical strength, can serve as the basis for load-bearing structures. Used in dry rooms.

- OSB-3 - strength characteristics allow to manufacture load-bearing structures and operate them in conditions of high humidity.

- OSB-4 - moisture resistant and durable material is used for the device of loaded structures. It has excellent performance, but its application is limited by its high cost.

OSB brand 3 is used more often than other types in construction work. Its popularity is due to its increased resistance to moisture and stress at an affordable cost.Osb slabs with a size of 1250 × 2500 mm are suitable for cladding external and internal walls, creating continuous sheathing, construction of temporary structures and fences.

By the degree of surface treatment sheets are:

- Unpolished - the products are rough, they are recommended as a base for a roof, serve as a base for a bituminous primer.

- Sanded - the surface is machined, it becomes smooth. The material is used as flooring.

- Lacquered - one side is primed and covered with transparent varnish.

- Laminated - paper impregnated with resins is applied to the outer layer, the coating is fixed by hot pressing. Purpose - device of reusable formwork.

The edge of the products is even or the ends are processed for a groove-comb connection.

Sheet Specifications

The popularity of oriented strand board is due to their technical properties and characteristics. The material does not have the disadvantages typical of natural wood and other sheet products made from it. It does not delaminate, no voids are formed due to fallen knots. Light weight allows for installation without involving cranes and blocks. OSB sheets easy to handle (cut, polished and drilled), they are fastened with any wood glue. The material is suitable for creating curved structures.

As an exterior finish, you can use varnishes, paints, primers, wallpaper.

When working with the material, it is recommended to wear a respirator to avoid the ingress of dust into the respiratory system.

- Moisture resistance - the degree of resistance to moisture depends on the type of board. It is low for materials of the osb-1 and osb-2 brands, while for osb-3 and osb-4 it is high. During testing, the sample is immersed in water for 24 hours. The degree of swelling is 12-25%, while the strength characteristics are preserved.

- Thermal conductivity - depending on the thickness of the product, the indicator is in the redistribution 0.08-0,16... This means that the material provides excellent thermal insulation characteristics to the structure.

- Vapor permeability - after polymerization, the resins do not allow air to pass through. The permeability of the slabs is low; when used for cladding, a reliable ventilation system is required.

- Flammability - flammability class of osb panels - G4... The material is classified as fire hazardous. It is highly flammable and has a high flue gas temperature. To eliminate the disadvantage, it is recommended to treat with fire retardants and use non-combustible building materials for finishing.

- Bending strength and modulus of elasticity - different spatial orientation of the layers increases the resistance of the product during bending and twisting. Flexural strength is 22 MPa, elastic modulus - 3500 MPa. Osb panels are superior to chipboard in terms of parameters, but inferior to plywood.

- Biological resistance - in conditions of normal humidity, the sheets are not exposed to mold and mildew. To protect the material from damage by microorganisms upon contact with water, it is covered with antiseptic compounds.

One of the components of the material are resins with formaldehyde content. Standards have been developed to determine the degree of toxic emissions in mg / m³ air:

- E0.5 - up to 0.08;

- E1 - 0.08-0.124;

- E2 - 0.124-1.25.

For interior decoration premises are recommended class products E0.5 and E1... To reduce the harmfulness of emissions, the surface of the panels is additionally covered with a finishing material.

Standard sheet sizes

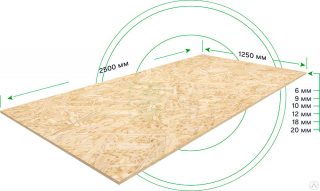

Regulated by a regulatory document standard dimensions: from 1200 mm and more with a step of 10 mm... Most manufacturers offer OSB boards size (length and width in mm):

- 2440×1220;

- 25001250;

- 2800×1250;

According to GOST permissible dimensional deviation is up to 3 mm in length and width, 0.3-0.8 mm in thickness.

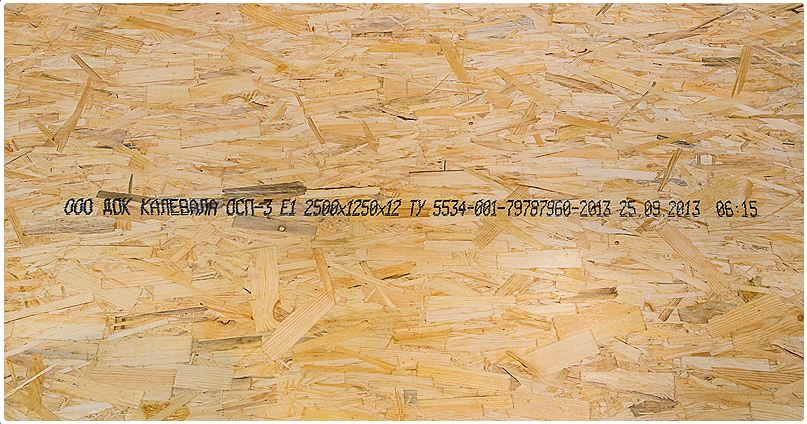

IN labeling products, their main parameters are indicated: type, degree of surface treatment, dimensions (length, width, thickness), toxicity level, manufacturer's name.

The use of OSB boards in construction

The main area of application of OSB panels is construction. The material is used for various purposes:

Sheathing of frame structures

The structure of the walls of frame housing construction consists of classic "pie": sheathing, insulation, windproof membrane. The base of the building is a wooden or metal frame. It is recommended to use slabs as external covering of spans. osb 3 and osb 4... They provide the necessary rigidity of the structure, are moisture resistant, and withstand high wind loads. Thickness of sheets from 13 mm.

Manufacturing of SIP panels

For the rapid construction of frame houses, SIP panels... This is a material consisting of two sheets of OSB, between which there is insulation - expanded polystyrene. The structure is held in place with adhesive. The products are lightweight, have excellent thermal insulation, rigidity and durability (they serve for more than 50 years). Thickness of osb sheets is 12 mm, insulation - 50-250 mm... SIP panels are joined through a bar, fixed with self-tapping screws. It turns out a flat wall that does not require additional work on thermal insulation.

Subfloor and attic flooring

Panels are suitable for creating durable flooring on logs (beams) and on a concrete base... The thickness of the slabs depends on the distance between the lags: at a step of 500 mm - 18-22 mm, at 600 mm - 22 mm... Thanks to the large sheet area, seamless flooring... It is compatible with any insulation and finishing flooring. OSB is not recommended for use when installing a floor heating system.

Installation of roof lathing

To create a continuous sheathing for soft tiles, it is recommended to use osb-3... Such sheets withstand wind and snow loads, are not afraid of moisture. When installing between the panels, leave a gap of 2-3 mm to compensate for thermal expansion. The thickness of the material depends on the pitch of the rafters and can be 10-27 mm... The slabs are laid with offset joints.

Internal and external wall decoration

The boards are mounted vertically or horizontally. Fasteners are threaded nails, wood screws and self-tapping screws. They are driven in (screwed in) with an indent from the edge of 10 mm... For interior decoration, sheets with an emission class are suitable E0.5-E1... The type of material depends on the operating conditions: smallpox-3 and smallpox-4 are taken for the outer skin. Smallpox-2 can be used in dry rooms.

Creation of removable formwork

When constructing the foundation of buildings to create reusable formwork, they use laminated oriented strand board... The panel structure must be on 10-15cm above the alleged concrete pouring level... Plates are reinforced with wooden beams. Opposite shields are fastened with steel pins, which are placed in a piece of plastic pipe.