Siding is one of the popular options for protecting the facade from the outside. This cladding material consists of panels fitted with invisible tongue-and-groove joints and mounted on a lathing frame. This design simplifies insulation and protects the walls from environmental factors. You can order turnkey siding or sheathe the building with your own hands. Self-assembly of panels will not be difficult if you have the skill of attaching facing materials to the crate. They can decorate not only the facade of the house, but also the gables of the roof, as well as the shed and other outbuildings.

Types of siding panels

There are several types of products that differ in the raw materials used for the base and operational characteristics. Residential building siding usually involves the use of vinyl products. PVC panels are lightweight and easy to install, moisture and wind resistant. They are available in a wide range of designs, including stone or wood finishes. They can serve up to half a century. If one of the panels is damaged, it is easy to replace it with another. However, at high temperatures, the products tend to expand, therefore, during their installation, a technological gap is left, and the screws are not completely screwed in.

Another option for polymer panels is acrylic. They are not as common and budgetary as vinyl ones, but they are devoid of two disadvantages that the latter have - changes in volume with temperature fluctuations and a tendency to fade from the action of the scorching sun. Therefore, such siding can be used to sheathe a building located in a well-lit area in the southern region.

Metal siding is also popular, which is distinguished by the best indicators of strength. They can decorate a house and an outbuilding. The panels are manufactured from galvanized sheet steel. A paint or polymer coating is applied on top (in the second case, the protective qualities are better). The disadvantage of such products is the tendency to corrosion, especially in cut areas and in the area of fasteners. Therefore, you need to choose the right screws and follow the installation technology.

Wooden panels are made from pressed sawdust or shavings. By the method of installation, they are similar to the clapboard. Wood-polymer composite panels are best suited for exterior decoration. They tolerate moisture and other environmental factors better. The disadvantage of this class of products is fire hazard.

How to calculate the quantity

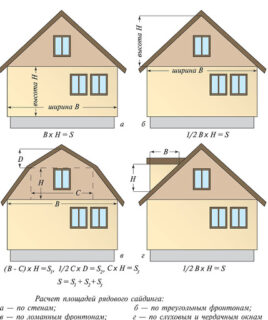

- The area of all walls and other planes that need to be sheathed is determined.

- The area of door and window openings is calculated and subtracted from the previous figure.

- The result is multiplied by 1.1 to give a 10% trim margin.

- The resulting number is divided by the area of a single panel (a useful indicator is taken, not a complete one).

The final number is rounded up to the nearest whole number. So many panels need to be purchased to be sure that there are enough of them for the work.

Warming recommendations, seasons, care

Insulation of a structure with siding can be carried out using different types of materials. If the climate is mild, roll options are well suited.Such insulation can be glued to the wall, and then organize the lathing for cladding directly along it. Since its thickness is small (as a rule, no more than 2 cm), this option will not work for cold areas.

Basalt wool is soft, semi-soft and hard. It is produced in slabs and creates good sound insulation. Can be installed under siding and fiberglass insulation. Such plates do not burn, do not absorb moisture, and do not interact with chemical agents. Their thickness may be different.

Foamed polystyrene is durable and devoid of hygroscopic properties, which makes it the best option for home insulation.

If vinyl siding is selected for cladding, it must be installed at an air temperature above freezing. In the cold, it becomes brittle and may crack during the cutting process. Other types of cladding can be installed at any time of the year.

The products are cleaned with a dry (in the case of wood) or slightly damp cloth. If the vinyl panels are heavily soiled and cannot be washed with water, use special cleaning agents that do not contain chemically aggressive components. Step-by-step instructions for their use are provided on the packaging.

Plating technology

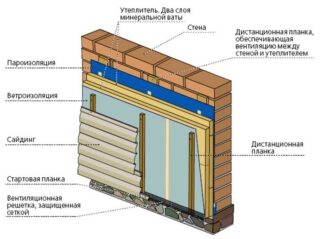

The siding sheathing technology involves fixing the panels to the lathing frame. The latter can be made of timber or metal profiles. It is easier to work with wood, it does not create cold bridges, but it does not tolerate moisture well. Therefore, the lathing timber must be well dried and treated with an antiseptic.

The metal does not retain heat well, so the support brackets are fixed to the wall using thermal insulation pads. The dimensions of the frame elements are selected according to the thickness of the insulation used.

Of the tools you will need:

- construction tape and level;

- a hammer;

- hacksaw suitable for the material;

- electric drill or hammer drill;

- Screwdriver Set;

- suitable fasteners.

Before installing the battens, window shutters, drain pipes and other structures that can interfere with the sheathing are dismantled. The spacing between the bars or profiles depends on the length of the gap between the holes in the panels. If the siding is vertical, the frame components are mounted horizontally and vice versa.

The insulation is attached to the openings of the lathing so that it adjoins the wall. It is often put on glue. It is recommended to cover it from above with a diffusion membrane that protects the walls from moisture. An additional crate of thin elements is made under it to create a gap of 2-5 cm.

Before installing the panels themselves, a starting bar is installed (the first siding unit is then fixed in its lock), corner and window profiles.

Fasteners are not screwed in until they stop: there should be a gap of 1 mm between the head and the plane of the panel.