The logs are processed on milling machines in order to give a special profile and get the same diameter along the entire length. Grooves are cut out in the product for ease of installation and locking joints. A rounded log is made with great precision, therefore, there are practically no gaps when assembling a log house. The material belongs to the category of inexpensive products that do not need to be additionally prepared for installation on the construction site.

- What is a rounded log

- Difference from chopped

- Applications

- Features of the production of rounded logs

- Classic method

- Pass-through method

- Positional method

- Glued log

- Equipment for the production of

- Manufacturing technology

- Sorting and preparation of material

- Drying

- Cylindering

- Trimming and slicing

- Treatment with protective compounds

- Closing events

- Varieties of building material

- Groove type

- Wood species

- Dimensions (edit)

- How to choose a log for construction

- Features of pricing

What is a rounded log

Features of use material:

- the set is ordered at the factory, while the elements have a length according to the house design, the grooves are made with great accuracy;

- this design reduces labor costs at the construction site.

A cleanly finished surface suggests rejection of external cladding with other materials... The log house is treated with varnishes, glazing paints, in order to only emphasize the texture of the wood.

At home gradually shrink in the amount of 8 - 10% from the initial indicators, so the building can be fully exploited after 1 - 1.5 years after construction. Cracks may appear at the ends at this time, so it is not recommended to heat the house during the shrinkage period.

Difference from chopped

From such material it's hard to build a perfect wall in comparison with a log house made of rounded logs. Longitudinal grooves are also cut out manually, therefore, only craftsmen are allowed to build a house from chopped elements.

Differences between materials:

- hand-cut trunks have different diameters along the length and an uneven surface;

- the construction time from chopped logs increases due to the need to fit each element.

After construction seams outside and inside need to be caulked, to remove gaps. Both materials require treatment with antiseptics, fire retardants in order to increase resistance to negative factors.

Applications

Other uses:

- log walls of baths and saunas are erected from conifers;

- annexes to housing, for example, closed and open verandas, walking terraces;

- a massive log porch looks beautiful;

- gazebos and sheds are built in the garden;

- enclosures for walking are being built for pets.

From rounded logs, they build strong fences with an original entrance group, make elements of a playground (houses, fortresses, bridges, sandbox walls).

Features of the production of rounded logs

Manufacturing technology is simple, but requires special equipment in the form a special line of machines for processing felled tree trunks.

The main production methods:

- the classic way;

- checkpoint;

- positional;

- gluing logs from individual elements.

Each technique has certain advantages and disadvantages over others, the methods differ in productivity, quality of work.

Classic method

Processing process:

- The barrel is fixed in the centers at the ends, then it is cylindrical.

- The cutters move along the log, the resource of the edges increases due to the stress relief from the finishing blade due to the load on the roughing blade, and the quality of cylindering increases.

- The resulting product is polished, impregnated with a protective compound against inflammation and mold.

The classical method is more laborious, therefore products are more expensive... Careful handling reduces the likelihood of size runs.

Pass-through method

Features of the technique:

- get low-cost, low-quality products;

- continuous feed of trunks is allowed;

- the length of the workpieces is not limited, but the logs should not fall into the space between the rollers;

- high performance.

The equipment is also used for the production of edged lumber, bars, lining, boards, slats. The disadvantage is that you need to select fairly smooth trunks, or cut semi-finished products into products 1 - 2 m in length.

Positional method

Features of the method:

- lower productivity in comparison with the continuous method;

- time is wasted on reconfiguring the machine according to the diameter of the logs;

- the need for skilled operators to improve the quality of processing.

It is possible to use two milling devices at once in order to simultaneously make a rough and a finish pass. The length of the workpieces depends on the size of the equipment.

Glued log

Production stages:

- cutting logs into boards;

- drying to a moisture content of no more than 12 - 15%;

- joining lamellas with high-strength glue with alternating fiber directions in subsequent layers.

Products are collected from solid boards or spliced along the length... The products alternate between two types of wood to improve performance.

Glued logs are distinguished by less moisture, they practically do not crack after being laid in a frame. The decrease in the number of cracks is explained by the lower internal stress in small parts, compared to a whole massive log.

Equipment for the production of

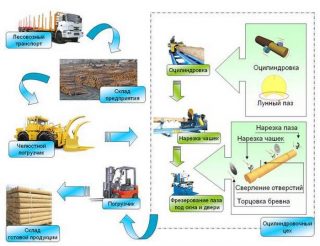

Production lines can be fully automatedwhen the machine feeds and loads the workpieces. IN semi-automatic In the variant, mechanization is considered within the working cycle, then manual labor is used with the help of forklifts and electric cars.

Types of machines:

- turning and milling (positional method);

- pass-through units;

- centering and broaching mechanisms;

- equipment for cutting cups, grooving;

- trimming installations.

The quality of the rounding of logs depends on the degree of sharpening and the type of cutting element of the machine, which are rotary, angular, milling.

Manufacturing technology

The technology includes the stages:

- drying of raw materials;

- directly cylindrical;

- cutting and facing;

- impregnation with protective agents;

- product quality control, marking according to the project, warehousing, packaging for dispatch.

The products obtained on automatic lines are distinguished by a lower cost than when using a share of manual labor.

Sorting and preparation of material

Production includes preliminary sorting of felled trunks, pruning... Raw materials are chosen so that initial radius at the top of the log exceeded by 20 mm similar size of products received... Dimensions are taken according to the customer's specifications for the construction of a house, more often spruce and pine are used.

If the positional method is used, the logs are sorted and by homogeneity of workpieces in terms of diameterto process the batch without re-configuring the machine, which will take time.

The automated sorting line is represented by a toothed conveyor with a scanning measuring mechanism and several "pockets", where the drives dump raw materials with uniform characteristics.

Drying

Moisture is reduced evenly in the outer and inner layers. This is paid attention to, since the outer parts give off more water, and the inner ones are delayed, which leads to the appearance of cracks.

Drying takes place in two ways:

- in natural conditions in a cool place under a roof (canopy);

- in drying compartments.

Artificial moisture removal takes place in a vacuum, infrared, electric chamber.

Cylindering

Operating procedure:

- make cylindering according to a strictly specified diameter;

- after the formation of the lunar groove, perform the compensation cut.

The unloading passage relieves the tension of the wood fibers under load, so that new cracks do not appear on the product after installation and shrinkage. The cut is made along the log in the form of an even groove with a width of 8 - 10 mm, its depth is ¼ of the width. When storing, the log is placed with a groove on top so that the next element closes the cut at the top and protects it from water ingress.

Trimming and slicing

Rounded logs cut into lengths... Optimization of products takes place in order to select areas without chips, large cracks and falling out knots. Short pieces are joined into parts of the desired length by splicing, for example, using a mini-tenon method.

Trimming is carried out in two ways:

- automatic;

- manually.

In the first case, the scanner detects 4 sides of the fed material, then moves it to the miter machine. At the end of the line, dumpers distribute the workpieces along the length. With the manual method, the worker identifies the defective spots and makes a mark with fluorescent chalk. The machine reads the mark and makes a cut at this point.

Treatment with protective compounds

Apply treatment with:

- antiseptics - from rot, mold, fungus, bugs;

- fire retardants - to reduce the degree of ignition.

They use hypoallergenic, environmentally friendly substances so that the walls of the house do not emit toxic components into the surrounding space.

Closing events

Finished products pass technical control. In the process, the dimensional accuracy is checked, taking into account the tolerances. Experts mark each log along the end to indicate its place in the design drawing, where the corresponding marks are also located.

Store lumber stacked in different ways:

- tight;

- rows;

- in bundles;

- packages.

Depending on the method, different spacers are used to ensure uniform load distribution and ventilation.

Transport to the customer in compliance with safety measures and the safety of the material, for this there is a special lengthy vehicle.

Varieties of building material

The essence of the construction of a wooden house is in the construction of a log house. If the ends fit well, there will be no gaps, gaps, therefore, the protection against cold and blowing increases.

The ends of the logs are joined in the following ways:

- "In the bowl" and "in the oblo" (with the remainder);

- "In the tooth" and "in the paw" (no residue).

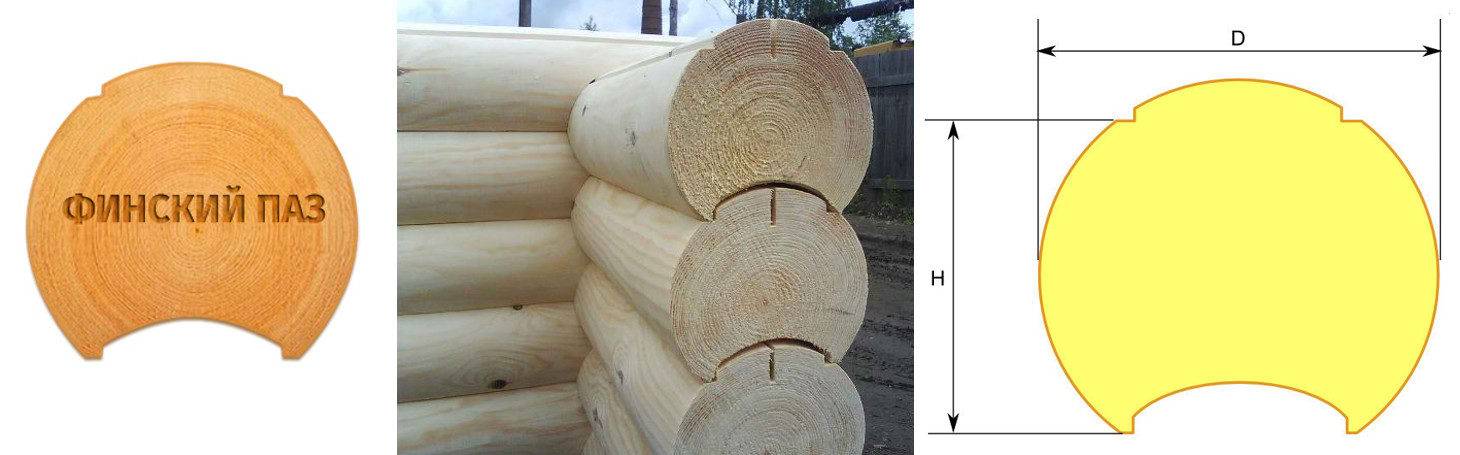

In rounded lumber, processing with a lunar and Finnish groove is used.

Groove type

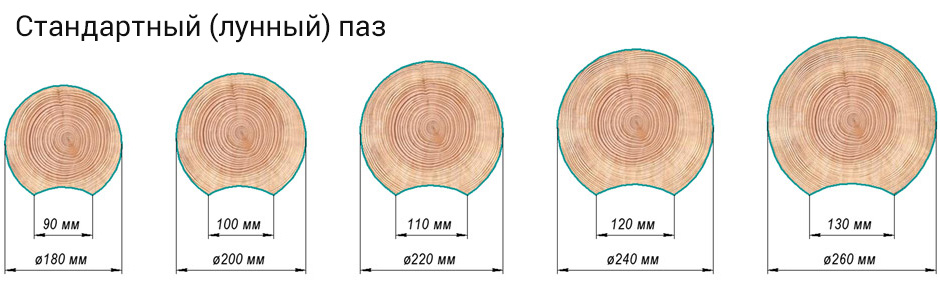

Moon groove used to tightly install the logs to one another during installation. The elements are mounted using a bundle insulation or mineral wool. Such a groove looks like a longitudinal cut, the section of which resembles a semicircle.

Sizes of logs with a lunar profile:

- A log diameter of 180 mm assumes a groove width of 95 mm;

- 200 mm - 105 mm, respectively;

- 220 mm - 116 mm;

- 260 mm - 137 mm;

- 300 mm - 158 mm.

Finnish groove differs in a more complex shape, since it is used for a mounting scheme with a groove and a ridge. There are gaps in its section - these are recesses to increase the thermal insulation of the docking places. The Finnish groove minimizes cracks and does not require caulking.

Wood species

Characteristics of the rocks for cylindrical logs:

- Pine - harder than spruce, with better strength properties;

- spruce - soft and warm wood, easier to handle with tools;

- larch - wood with natural moisture-insulating qualities, durable;

- cedar - rarely used due to the increased cost of wood.

Larch is twice as expensive as pine and spruce.

Dimensions (edit)

The choice depends on the place of use:

- baths, dachas, outbuildings - 160 - 180 mm (south of Russia);

- summer residential buildings, garages, gazebos - 200 - 220 mm (European part);

- permanent residence houses in Western Siberia - 240 - 320 mm (with an insulated attic).

How to choose a log for construction

Preference is given to firms that release material and carry out construction at the same time... They are responsible for the quality of the logs. Better before placing your order find out about the place of extraction of raw materials, storage conditions and delivery.

Outwardly distinguish quality based on:

- material in dark yellow and yellow colors;

- no wormholes, resin pockets, mechanical defects;

- a few small knots are permissible;

- the cuts are even, the trunks are not twisted;

- all workpieces are of the same radius and length.

When accepting logs from the supplier, check presence of marking in accordance with the project, otherwise the installation will be difficult.

Features of pricing

The price of lumber per cubic meter depends on the diameter. Approximately: 180 - 190 mm - 7,500 rubles, 220 - 230 mm - 7,800 rubles, 260 mm - 8,000 rubles, 300 mm - 9,500 rubles, 320 mm - 11,000 rubles.

Price changes based on factors:

- the presence of a diagonal groove;

- type of packaging (film, pallet, tape);

- making holes for the installation of pins;

- milling space for window and door trim;

- milling of recesses for the installation of window and door fillings;

- impregnation with protective agents.

The final cost is affected by delivery price... If the construction is carried out in the steppe regions, delivery will significantly increase the cost of the material.