The tongue-and-groove locks on the sides of the building blocks provide a strong and stable wall structure. They are produced solid and hollow - in the form of monolithic elements, and stones with round holes inside. For partitions in an apartment or a private house, lightweight tongue-and-groove blocks are used. Moreover, they better protect against noise. For load-bearing walls, full-bodied elements are used.

- Partitions made of silicate and gypsum tongue-and-groove plates

- Features of silicate blocks

- Technology for the construction of partitions from silicate plates

- Partition construction instructions

- Marking the future structure

- Aerated concrete slab cutting tools

- Laying the first row

- Strengthening the structure

- Ligation of butt seams

- Attachment to supporting structures

- Electrical wiring device

Partitions made of silicate and gypsum tongue-and-groove plates

Structures are assembled from separate blocks, while large blocks are characterized by increased manufacturing accuracy... The norms provide for a deviation from the dimensions during molding of no more than 1.5 mm.

The tongue-and-groove slabs (GWP) divide into two types depending on the raw materials used:

- Silicate. Produced by the method of silicatization of quartz sand under the influence of pressure in a high-temperature regime. As a result, a durable material with good consumer qualities is obtained.

- Plaster. Gypsum is used as a raw material, therefore, the initial characteristics are improved by the introduction of additives to increase moisture resistance and strength.

Manufacturers use their own specifications in the manufacture. They produce tongue-and-groove slabs for partitions, the thickness, width and height of which may vary. Common sizes: 667 x 500 mm, 300 x 900 mm; 250 x 500 mm, 600 x 200 mm. For interior partitions, a thickness in the range of 70 - 100 mm is used.

Features of silicate blocks

Silicate blocks are used more often due to their greater density and strength. Gypsum tongue-and-groove partitions are easier to assemble, since the products are simply cut and drilled, providing better sound insulation.

Technology for the construction of partitions from silicate plates

Important is correct prepare the foundation... The slabs have clear dimensions, so the surface must be flat.

Technological techniques:

- to reduce noise from the lower floor, a special soundproofing tape is placed;

- the laying of partition tongue-and-groove blocks is done with bandaging of the seams;

- sawing stones outdoors or in a well-ventilated area, wearing a respirator;

- be sure to reinforce walls and internal partitions;

- the structures fit correctly with the side, vertical surfaces and the floor.

For registration door or window lintel in the slabs of the last row, cutouts are made 15 - 20 cm deep. A metal channel or a wooden beam is used, the elements are placed on glue or mortar.

Partition construction instructions

Unevenness on the floor is eliminated by pouring a cement-sand screed.If the partition is placed on the finished floor, mark the masonry line, then cut the topcoat in the resulting area to the base. Also available with side connection to the wall.

Do not put GWP partitions on parquet, laminate, linoleum, tiles, dock with wallpaper, painted surfaces.

The upper blocks are sawn to lengthso that they fit into the groove under the ceiling and it is possible to press them against the previously laid tiers. The void formed above them is sealed with foam.

Irregularities and chips during the masonry process, they are filled with glue, gypsum or cement mortar.

After laying, the structures of the partitions do not need to be leveled, you can immediately proceed to the finishing (putty, then painting, wallpapering, tiles).

Marking the future structure

Masonry lines are applied on the floor according to the project or according to the desired location. The markup is transferred to the ceiling, while the tip of the plumb line, lowered from a point on the ceiling, should coincide with a similar point on the bottom.

Markup features:

- it is better to use a laser level, which at the same time replaces the plumb line, bubble level and carpentry square;

- for the first and subsequent rows, pull the cord showing the top of the working row;

- vertical lines are drawn on existing walls to accurately indicate the side joint.

On the floor in the marking area indicate the boundaries of the doorway... It is better to choose its location so that the installation of the blocks takes place with minimal clipping... In the process of laying check verticality partitions from the tongue and groove, and also correct the curvature in the plane.

Aerated concrete slab cutting tools

Cutting solid slabs by hand is not easy. Use a special hacksaw. Sometimes the plane helps.

Electrical tools are used:

- Bulgarian;

- jigsaw;

- Circular Saw.

For gypsum-based tongue-and-groove slabs, circles are used on wood, and silicate stones are cut with discs on stone.

Laying the first row

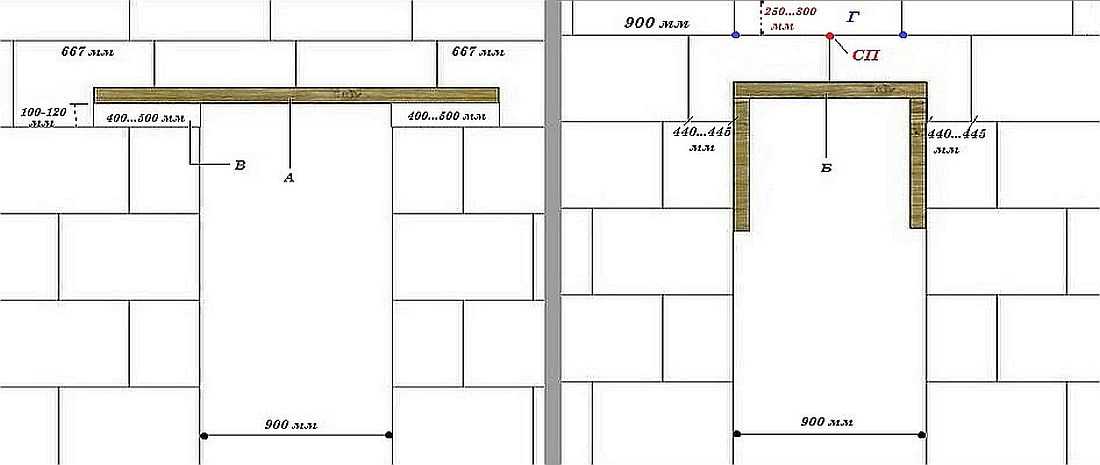

For blocks intended for masonry in the first row, use a hacksaw cut the support legs... Before installation, a seal is placed, mortar and stones of the initial row are placed on it.

Next steps:

- a perforated bracket piece is inserted into the groove of the first block in contact with the side wall so that it protrudes 1 - 2 cm above the element;

- the plate is set up with a groove, leveled, pressed against the wall, floor, help with a mallet;

- the bracket to the wall is fixed with self-tapping screws;

- at the bottom, a piece of brackets is placed in the groove from the side where the second block will stand, they are attached to the floor with dowels.

If the first row is obtained with a slope, the subsequent rows will stand the same - it will not be possible to align because of the strong locks at the ends of the elements.

The mortar or glue is applied so that the thickness of the joint is no more than 2 mm. It is better to use a special dry glue mixture, which for use is sealed with water according to the instructions.

Strengthening the structure

At the corners of the tongue-and-groove walls and partitions, a stamping mesh is fixed, it is installed after 3 - 4 rows in height.

Ligation of butt seams

Block masonry with grooves and ridges is performed according to the principle of working with bricks. Also mismatch of seams between adjacent elements is not allowed... The bandage between horizontal and vertical sutures should be more than 2 cm.

Dressing rules:

- to fulfill the mismatch condition, you need to cut off the halves and quarters of the elements;

- take into account the location of the grooves and ridges so that the end joining is carried out by the locking method;

- the height of the door lintel must match the same block size;

- in openings up to 70 cm in width, you do not need to put a lintel.

If the beam is not placed above the door, a temporary support is used to assemble the masonry from the blocks. Remove it after the solution has solidified.

Attachment to supporting structures

The partition is fixed to walls, floors and ceilings using various details. They must be durable, have an anti-corrosion coating, for example, a galvanized layer.

Apply options:

- mounting angles 100 x 100 mm;

- corrugated wire with a diameter of 6 - 10 mm;

- staples C3 and C2;

- ES hangers from plasterboard system.

With a standard room height (2.5 - 2.8 m), 3 fasteners are made vertically. Along the length on the floor and ceiling, fixation is provided every 70 - 100 cm.

Electrical wiring device

Wires in partitions made of GWP are laid using hollow blocks... To design holes for wiring boxes, internal sockets, switches, cutting crowns are used, which are installed on the drill pulley.

Rules for laying wires:

- planning the location in advance in order to drill a hole in the slabs when they are not already installed in the structure;

- for laying along the wall, make grooves with a chasing cutter;

- it is undesirable to use an impact drill or hammer drill.

The made channels, holes are cleaned of dust and primed, after laying the cable, the grooves are sealed with putty or gypsum mortar.