Polyurethane foam-cement is a universal product, its characteristics allow its use in many construction works, during the repair, reconstruction of objects. The microporous structure provides resistance to harmful chemical and mechanical influences.

Description of material and characteristics

Features of foam cement:

- fresh material, when leaving the cylinder, smells a little of polyurethane, but after setting and final solidification, the smell disappears;

- when the foam is in water, the pores begin to absorb moisture, which negatively affects the further strength;

- a homogeneous mixture is squeezed out of the cartridge using a special device, while the volume increases by 1.5 - 2 times.

Can be used on wet surfaces, but adhesion of snow and ice is unacceptable... The composition is completely ready for use, does not require dilution or mixing.

- density - 20 kg / m³;

- a film on the seam forms in 5 - 8 minutes;

- full hardening time - up to half an hour;

- when solidifying, the volume changes by 5% in the direction of increase;

- water absorption under normal conditions - no more than 1% per day or no more than 10% per month;

- the solidified mass absorbs 60 dB of sound waves;

- thermal conductivity at the level of 0.037 - 0.4 W / m · K;

- operating temperature parameters - -40 - + 90 ° С, short-term exposure to + 110 ° С is allowed, fresh foam can be used at a temperature of -5 - + 35 ° С.

Varieties and scope

- Shaketes - the universal version is used all year round.

- Winter - you can fix the elements, make laying in dry and frosty weather. Most often used for roofing, sealing window and door openings.

- Premium - luxury material based on polyurethane for professional use. The foam at the exit doubles, therefore, it belongs to the options that are economically advantageous. The cans are equipped with a removable pistol.

- Premium Mega - the product can be used without problems in frost down to -15 ° С, the material has a high degree of adhesion.

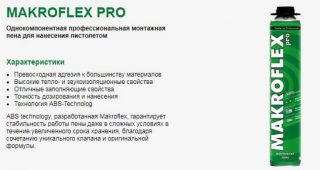

- Pro - Has good adhesion to porous surfaces. It is completely organic without carbon and chloride components.

- Whiteteg - ultra-strong cement-polymer foam of white color, resistant to ultraviolet light. They are more often used in carrying out and installing communications for attaching them to the wall.

Universal cementitious foam adhesive replaces many bulky dry mortar bags that need to be diluted with water before use.

- installation of stairs, window sills, window frames;

- fixing lintels over openings;

- laying bricks, stones, aerated concrete, repairing destroyed walls;

- fastening insulation boards to the wall, floor, ceiling;

- decorating surfaces in the room with various materials;

- sealing of cracks, voids, butt joints.

The masonry of the outer walls is carried out, and foam-cement is also used for internal partitions, walls.

Recommendations for use

Foam can be used in frostbut for this her contain several hours in a warm roomwhere the air temperature is not lower than + 15 ° С. A small ball is placed inside the container, which helps to mix the composition before work. The product is shaken so that the release of the composition occurs more evenly.

Others terms of use cement glue:

- before applying the contact surface is wetted with water using a brush or spray;

- a special tube is installed on the top of the spout of the container, then the can is turned over upside down;

- if a professional pistol is used, the position of the top and bottom is also changed;

- vertical the seams are filled from bottom to top;

- before further work withstand time until solidification, in warm weather, the foam sets faster than in winter.