Building a partition from aerated concrete blocks in a house or apartment is a simple and quick way to divide a large room into two or more functional zones. The work can be done independently, but it is necessary to familiarize yourself with the nuances of the technology and choose the right material.

Wall requirements

To ensure a comfortable and safe stay in a room, internal partitions must meet several important requirements.

Pay attention to the following parameters:

- Strength - the partition must withstand accidental impacts, and the weight of objects placed on it - TV, microwave oven and others.

- Weight - the building structure should not exert undue influence on the floors.

- Fire safety - the wall material should not support combustion and should not emit harmful substances when heated.

- Sound insulating properties important when you need to protect yourself from the internal noises of household appliances and sounds coming from neighboring rooms.

- Environmentally friendly materials.

Aerated concrete partitions correspond to the specified properties, therefore they are popular with professional builders and individual developers.

For the installation of heavy objects, specially designed mounts are used, which distribute the load over a large area.

Selection of aerated concrete blocks

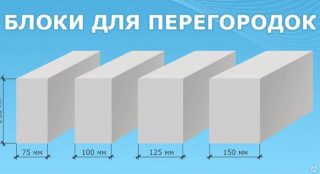

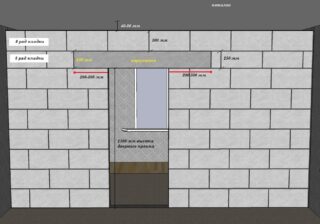

The thickness of the interior partitions made of aerated concrete blocks is determined depending on the length of the wall and the height from the floor to the floor:

- up to 2.5, blocks with a thickness of 75 mm are chosen;

- from 2.5 to 3 m - 100 mm;

- from 3 to 5 m - from 200 mm.

If the wall will carry a load in the form of any heavy objects, products with a thickness of 75 mm are not used. They are also not used if doorways will be made in the wall.

Good svisco-insulating properties has a partition made of aerated block thickness 150-200 mm... If the parameter is important, do not use products of 75 and 100 mm. Partition gas block with density index D500 or D600 is the best solution if the wall will act load up to 150 kg... Lightweight partitions can be made of material with characteristics D350 or D400.

Tools and materials

For the construction of the wall and its decoration you will need:

- a drill for attaching the corner at the junction of the partition to the walls;

- a dosing carriage that evenly distributes a thin layer of glue over the surface of the block or a toothed trowel if the volume of work is small;

- file for cutting blocks;

- building level and square, painting cord with paint powder:

- rubber mallet;

- aerated concrete brush and trowel;

- container for mixing the adhesive.

For masonry acquire required amount of glue, the consumption of which is indicated on the packaging and may vary from manufacturer to manufacturer.

Each block at the point of abutment to the load-bearing walls, ceiling and floor is fixed with galvanized strip or hangers, they are acquired after carrying out accurate calculations of the material. Fastening is carried out using special dowels.

If the span of the partition is more than 3 meters, it needs reinforcement polymer rod. The reinforcement is laid after 3-4 rows, based on this calculation, consumables are purchased.

It is undesirable to use metal fittings. Interacting with the lime in the block, the steel rusts, and brown spots appear on the wall.

Step-by-step instruction

- markup;

- waterproofing;

- installation of anti-vibration pads;

- laying blocks and fixing them to walls;

- reinforcement according to the arrangement of the rows;

- production of doorways, through niches and lintels over openings;

- arrangement of abutment to the ceiling;

- finishing.

Each stage is performed observing the technology.

Markup

Most often, aerated concrete partitions are built after the construction of the building frame... If done earlier, at the stage of installing the interfloor overlap, damage to the blocks or destruction of the entire partition is possible.

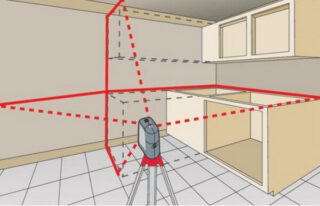

Use a laser plane builder or get by with a bubble level and a plumb line:

- At the intersection of the ceiling and opposite walls mark two points... In these places, one of the sides of the partition will be located in the future.

- Painting cord hitting a straight lineconnecting previously plotted points.

- Using a plumb line, project the markings onto the floor.

- Top and bottom notch connected with a line, which will indicate the place where the partition adjoins the walls.

Waterproofing and vibration prevention

On top of the waterproofing and on the walls they are fastened vibration damping layer... It protects blocks and plaster from cracking from vibrations, and also reduces the noise level penetrating into adjacent rooms.

As vibration damping pad use:

- mineral wool cardboard;

- expanded polystyrene sheets up to 5 mm thick;

- pieces of cork lining;

- soft fibreboard.

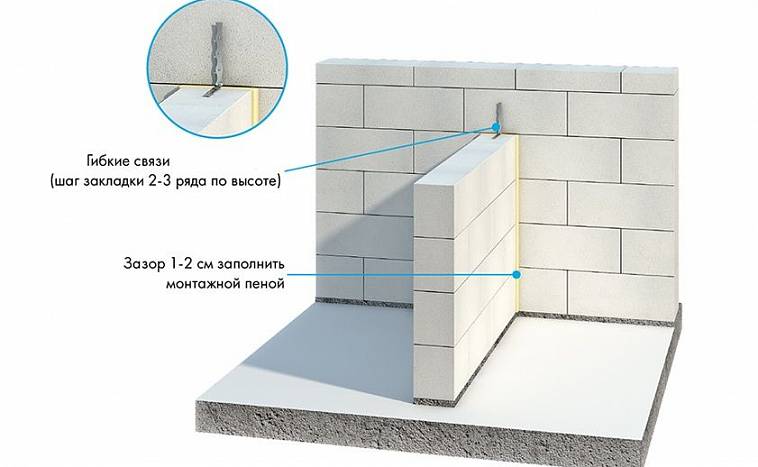

If the gasket on the walls is not installed in advance, at the end of the erection of the partition, the slots are foamed with mounting glue for aerated concrete blocks.

Laying the first and subsequent rows

The level of adjacent blocks must be maintained when laying the first row, the consumption of glue and, to a greater extent, the reliability of the entire structure depends on this.

Stacking algorithm aerated concrete blocks:

- Nailed along the mark on the wall flat rail, which will provide convenience when leveling the partition vertically.

- Lay on the mortar along the floor markings construction mesh made of polymer or metal - this will reduce the likelihood of wall cracking.

- Work begins from the load-bearing wall, at a distance of 1–5 mm from which the first block is installed. For leveling, light blows are performed with a rubber mallet.

- After laying the first row give the opportunity to solidify the solution, since during the installation of the second row, movements are possible that violate the geometry of the wall.

- The block is attached to the wall using soft metal suspension... Rigid corners and rods embedded in the load-bearing wall are not used, since the block will gradually collapse during vibration.

- To provide bandaging the rows, cut one block in the middle. If the partition is doorway, then the marking for cutting is carried out taking into account it. In some cases, the block will have to be cut in different ways.

- Before starting to lay each next row, the previous level with metal graters... Cut off protrusions and irregularities between adjacent blocks. The surface must be flat and horizontal to avoid excessive stress in the blocks.

- Pull on marking cordto make it easier to align the second and subsequent rows.

- Used as a binder solution special glue for gas blocks... The distribution of the composition is carried out with a purchased or home-made carriage. After each application, the body of the device is cleaned of glue, as it quickly sets.

- After three rows, the first is laid reinforcement layer... A groove is made in the surface, into which the glue is laid. Along the entire length of the partition, reinforcement is laid in the strobe and the groove is filled with glue.

- They continue to lay out the rows until they reach the ceiling.

- Between the last row and the overlap leave a compensation gap of 15 - 20 mm, which is filled with polyurethane foam at the end of construction.

The size of the blocks is adjusted with a file. Cutting with an angle grinder creates a lot of dust that is difficult to remove completely before glue is applied to the block.

The procedure for making openings

Aerated concrete partitions are not load-bearing walls, therefore, reinforced concrete above the doorways jumpers are not installed.

For placing blocks over standard doors width from 600 to 800 mm use a steel corner with shelves of 30-50 mm. The corners should be 50-60 cm longer than the opening to ensure a secure intersection with the walls of the partition.

If the width of the span requires the installation of two blocks, they are cut in such a way that the seam was over the middle of the doorway.

For long arches, not a corner is used, but channel with a suitable width for the block. The channel is embedded in the wall. Supports are installed under the partition of the arch so that the channel or corner does not bend. The support is removed after the glue has dried.

An alternative option for arranging the floor is fabrication of a reinforced belt:

- A wooden box is made as wide as a partition, and 4–5 cm high.

- Lay three rods of reinforcement with a diameter of at least 12 mm.

- Pour the box with glue or cement-sand mortar.

- Install aerated concrete blocks without waiting for the solution to dry.

- The formwork is removed after 2–3 days, when the glue has completely hardened.

The rows above the lintel are installed last.

Before finishing, if necessary, the partition is gated, electrical wires are laid, and socket outlets are mounted.

Finishing

Aerated concrete walls must be finished. Start work not earlier than in a month after laying. This is because the material shrinks 2-3 mm per meter of height and the finish will be destroyed.

Most common cover options for partitions:

- clapboard of various types - wooden, plastic, MDF;

- plaster for painting;

- wallpaper.

In the first case, they stuff on the wall crate, to which the lining is attached. Be sure to leave expansion gaps 3-5 mm from the floor, ceiling and walls.

Before plastering, the partitions are primed with deep penetration compounds.

Before buying a primer, you need to make sure that it is suitable for aerated concrete blocks.

For leveling and subsequent puttying, acquire special formulations... The walls of aerated concrete are flat, so the consumption of plaster will not be large and will not entail significant financial costs.