Glassine is a bituminous material designed to insulate coatings from moisture. Laying is carried out on the finishing of the pitched roof, walls and floor. It is mainly used as a vapor barrier for baths and saunas.

Scope of use of glassine

The use of glassine in construction eliminates the risk of condensation forming on the finishing materials of structures, in particular, this applies to the roof and floor. The lack of protection of materials leads to the rapid absorption of moisture. This leads to loss of performance and destruction of structures. Waterproofing increases the service life of the building's main structural elements.

Glassine, along with roofing felt, was first used in the construction of the Komsomolskaya station in 1933. Engineers used multilayer material for an underground box 155 m long and 16.8 m wide.

Application area

The main scope of glassine is the construction of baths and saunas. However, the material is not used in the construction of steam rooms. This is due to the release of toxins and an unpleasant odor when heated. Glassine belongs to the class of rolled products and is laid on top of heat-insulating materials under a hard coating, for example, under siding.

Thanks to its elastic structure, it is convenient to use as a roof waterproofing. But builders do not recommend using it for soft materials, such as shingles. This is due to insufficient insulation on complex elements - skates, valleys, etc. Incorrect fixing of the substrate leads to the sliding of the finishing material along with the vapor barrier.

Lumber structures are covered with glassine at the junction of concrete and soil. The formation of a protective layer reduces the risk of wood decay processes. Installing a vapor barrier between different surfaces prevents condensation from forming.

Characteristics of glassine

Properties

In the construction of technical structures and buildings, 3 types of materials are used, which, despite the general features, have different technical indicators. The table shows the types of glassine and their properties:

| Density of glassine, g / m2 | 250 | 300 | 350 |

| Covering area, sq. m. | 20 | ||

| Breaking strength, kgf | 22 | 27 | |

| Moisture resistance, kgf / cm2 | 0,01 | ||

| Resistance to aquatic environment, h | 10 | 22 | |

| Material width, mm | 1000 | 1025 | 1050 |

| The level of vapor permeability of glassine, mg / (m * h * Pa) | 0,001 | ||

In the production process, a deviation of 5 mm is allowed. According to building standards, such a change in parameters is not a defect.

Pros and cons

Before using rolled waterproofing material, it is necessary to study the properties, positive and negative sides of glassine. The advantages of the products include:

- Low cost of a vapor barrier in comparison with modern counterparts designed for the same purposes.

- The versatility of the canvas - use as a vapor and waterproofing.

- Easy Installation - Installation requires metal staples, glue or duct tape.

- Low weight does not require structural reinforcement or building foundations.

- The damaged area during operation is repaired by dismantling the old coating.

- Medium water absorption and tear strength.

Minuses:

- laying on a wet surface is not recommended;

- installation in frost leads to a violation of the integrity of the sheets;

- UV radiation destroys the structure of the material;

- the release of toxins and unpleasant odors when heated.

The composition of the cardboard contains non-woven materials that contribute to absorbency. The quality of glassine depends on the pressure of the press in the manufacture of cardboard. The optimal parameter is 300 g / m².

Types of material

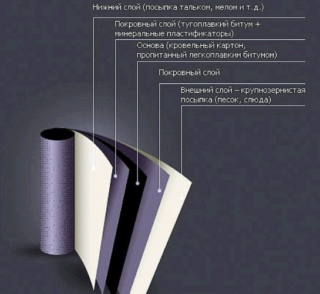

Products labeled by the state standard have high quality indicators, which affects the price of products.

Manufacturers offer the following brands of glassine:

- P-250 - is resistant to constant exposure to water for up to 10 hours.

- P-300 - withstands moisture for 20 hours.

- P-350 - has water absorption up to 30% of its own weight. Used as roof vapor barrier.

The P-250 grades were not produced in accordance with GOST, and the P-35 is no longer produced in accordance with the state standard, since the material is considered obsolete.

Liquid glassine is a polymer composition that displaces water from porous materials. It is used as a waterproofing foundation, wall and floor coverings. When arranging the roof, the composition is used to impregnate the rafter system. It resembles liquid rubber in consistency.

Laying rules when installing the roof

Before laying glassine, it is necessary to clean the surface of debris and dust the roof as much as possible. If the roll is hard, leave it in the sun or in a warm room to avoid crushing the sheets. Roll out the material after softening it.

Installation of glassine is carried out with one of the following tools:

- mastic;

- bitumen;

- wood stapler;

- construction tape.

The work is carried out with positive indicators. When arranging a bath, it is recommended to install a vapor barrier on both sides of the insulation. After installing the glassine, a layer of mineral wool must be installed. The material is laid with an overlap of 15 cm.

Alternative to glassine

Roof structures with bituminous coating have a short service life, therefore, they require repairs every 5-6 years. Glassine does not have a high level of elasticity and becomes stiff over time. This leads to deformation of the canvas under the influence of moisture, temperature changes and natural shrinkage.

For these reasons, the material does not compete with modern brands of heat insulators in terms of functional properties and service life. If necessary, you can use its analogues - rubemast, stekloizol and euroruberoid. At the time of purchase, experts recommend giving preference to dark-colored models. The presence of a brown tint indicates a lack of bituminous impregnation.