For effective work with polyurethane foam, special guns are used. Devices allow economical use of material, since it prevents solidification between uses. The best polyurethane foam guns are tools that are comfortable to hold in your hand and will not deteriorate with repeated use.

- Description and features of polyurethane foam guns

- Design

- Scope of application

- Varieties of pistols

- Criterias of choice

- Terms of use

- How to insert a can of foam

- How to apply foam or sealant

- How to replace a cylinder

- How to clean a pistol

- Care advice

- Malfunctions and methods of their elimination

- Rating of manufacturers and models

Description and features of polyurethane foam guns

Allocate two models of pistols:

- Unbreakable the structure is cheaper, but not intended for repair. In the event of a breakdown, such a device is discarded.

- Tool with a collapsible structure differs in the ability to repair the product. The pistol is untwisted, the parts are cleaned, and lubricated.

Cylinders for household use sell with disposable tube adapter. The filling density of the container is lower than that of professional options, therefore, such cylinders are used for small-scale works.

Design

The structure is conventionally divided into the elements:

- A tube. It is equipped with a pair of lug valves of different diameters to create pressure. This design improves the efflux of the expanding foam.

- Trunk. With its help, deep cracks are processed. The element reaches 20 cm in length, it can be collapsible and one-piece. In the first option, cleaning is facilitated, the service life is extended.

- Reducer. Using a universal device, the cylinder is connected to the gun. The mechanism takes the main load, therefore, it is made of steel, and inside the ball valve controls the air supply and foam output.

- Adjusting bolt. It is located near the handle, fixes the trigger in the closed position at the end of work, coordinates the foam stream.

- Trigger control lever. Press down to adjust the foam output speed.

The fastening part in the form of a nut is responsible for connecting the cylinder. The grip is plastic or metal with finger recesses.

Scope of application

Types of jobs:

- installation of window and door fillings;

- insulation of gaps between slopes and frames, loot;

- insulation device for roofing works;

- sealing various seams and surfaces;

- installation of heating, water supply manifolds, air conditioning systems for sealing gaps in the circuit;

- filling of various cracks, open gaps, bends, voids, connecting gaps;

- fastening light tiles to the wall, floor;

- repair processes;

- sound insulation, thermal insulation of vertical and horizontal surfaces.

Access to the mating surfaces is not always open, so using a gun is appropriate to transfer the foam to the right place.

Varieties of pistols

If difficult areas are not foreseen, devices with short tubes are purchased:

- 100 - 150 mm - for easily accessible seams, open surfaces;

- 150 - 200 mm - standard universal size for all types of work;

- over 200 mm - for semi-closed places.

Criterias of choice

When buying, pay attention to tool material... A trigger and a handle are allowed from plastic, metal is recommended for other parts. Teflon layer prevents foam from sticking, prolongs service life.

Factors are taken into account:

- the possibility of disassembly;

- barrel length, its inner coating;

- handle shape (for comfortable work);

- smoothness of the starting mechanism for effective regulation of the output;

- gun weight;

- the presence of nozzles, a regulator;

- dispenser cycle unit;

- integrity of the gearbox.

A high-quality product has clear joints of parts. There is no lubricant on the body, no defects.

Terms of use

The installation or insulation process will be more efficient if the gun is used correctly. Skillful handling will prolong the operating time of the mechanism. After purchase, specialists check the foam gun for operation of the valves... It is not the foam that is used, but the cleaning liquid. The spray can of the cleaner is equipped with a piece of attachment to the gun, as well as the container with polyurethane foam.

Several clicks are made so that the composition fills the inner container of the pistol. The balloon with liquid is removed from the device, the instrument is left for 2 days. After this time, start is pressed. A characteristic pop should be heard. This means that the cleaning liquid has not left the compartment thanks to the reliable valves. Air does not penetrate inside, the required pressure is maintained. If not, the gun is returned to the seller.

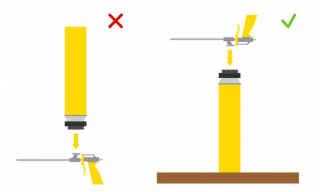

How to insert a can of foam

Next steps:

- the balloon is placed upside down;

- the adjusting screw is turned counterclockwise by a quarter of a turn, the trigger is pressed;

- make a test release of the foam, look at its consistency, press again to adjust.

How to apply foam or sealant

Work process:

- the tool barrel is brought to the seam, the trigger is pressed;

- the composition is applied in layers so that the tip of the barrel is immersed in the foamy mass;

- foam volume is coordinated by the trigger stroke;

- after the end of the application, block the adjusting bolt

Before starting use, check the serviceability of the tool. When applying, the barrel of the gun is positioned at an angle of 90 ° so as not to obstruct the view of the treated area. The foam is applied smoothly, considering the increase in volume. In the gaps, the space is half filled.

To use foam, you need to wear gloves, glasses, it is recommended to provide room ventilation. Do not point the pistol towards animals and people.

How to replace a cylinder

Operating procedure:

- turn the pistol upside down;

- open the adjusting screw clockwise;

- squeeze the trigger;

- unscrew the empty container;

- put a container with rinsing, clean.

After that, you can wind up another balloon with polyurethane foam. The pistol is shaken together with the installed cylinder (30 seconds). The frozen foam is removed from the tip of the barrel with a knife. Then unscrew the adjusting bolt and release the foam until a uniform flow is obtained.

How to clean a pistol

If the case has dried composition, the cleaner is unscrewed, the case is processed from the outside. Put on a cylinder with an insulator and continue to work.

Flushing compound is sold with the gun or separately. The liquid is packaged in cylinders similar to containers with foam. If after rinsing there are still parts of the foam inside the instrument, the procedure is repeated until it is completely cleaned.

Care advice

According to the instructions keep device needed with screwed cylinderso that the foam in the tool is always ready for application (under pressure). If you remove the container, foam or sealant hardens in the barrel, you will have to additionally disassemble and clean the device.

If the device is used regularly, cleaning is suggested every three months;

A device with a wound cylinder must not be left near heat sources or under the influence of the sun.

Some users prefer manual cleaning... To do this, the gun is disassembled into parts, the dried remains of the composition are removed. Use a rag and solvent. Use a wire or thin screwdriver for the nozzle where it is difficult to push the rags through. Clean carefully so as not to damage structural elements.

Malfunctions and methods of their elimination

Major malfunctions tools when clogged with foam:

- blockage appears at the exit from the trunk;

- the foam dries up inside the valve to which the balloon is fixed.

Rating of manufacturers and models

Brief model characteristics:

- Biber Master 60.111. It is characterized by good quality at a low cost, withstands serious loads. The model is collapsible, the box is plastic or metal. The pistol weighs 670 gr.

- P.I.T P 7000.003. Low quality Chinese brand for single use. In the model, the barrel and valve are steel, the rest of the spare parts are made of plastic. The body is not disassembled, the instrument weighs 400 g.

- Stayer Master Econom Max 06/861. Presents a simple model with a non-separable metal body and high quality PVC. The tool weighs 410 gr.

- Blast Extra Lite 59.0024... The non-collapsible plastic version is inexpensive. Users purchase a single-use, low-volume model. Weight 510 gr.

Other brands are also popular in the Russian market: Matrix, "Zubr", Hilti, Finch Indastrial Tools... The models of these manufacturers are of high quality, the cost is not high.