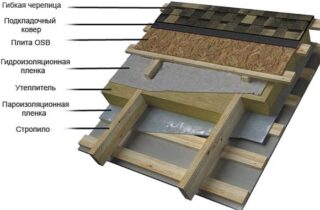

If the roofing is made of flexible soft material - ondulin, bituminous shingles - in addition to the usual rafters and lathing, a lining carpet will be required. The device performs several functions and compensates for the disadvantages of soft flooring.

What is a roof backing carpet

After laying a soft roof for 2-3 years, tiles and sheets gradually stick together under the influence of the sun and create a durable waterproof structure. Until then, however, the roof is vulnerable to water flow. If you don't worry about additional protection, the roof will leak. Bonding tiles on damaged areas will no longer occur.

Underlay carpet under shingles performs the following tasks:

- aligns flat and compensates for dents and grooves;

- provides waterproofing, especially in vulnerable places: valleys, cornices, abutment to the pipe;

- gasket seals the puncture site when attaching a self-tapping screw: bitumen tightens around the hardware leg and prevents water from entering.

To some extent, the carpet helps to evenly distribute the load on all parts of the roof.

Lining carpet is often considered a waste of money and time. However, in practice, this approach is justified only in regions with a dry, stable climate. Ignoring the recommendations in rainy areas is fraught with constant roof leakage.

Varieties of lining carpets

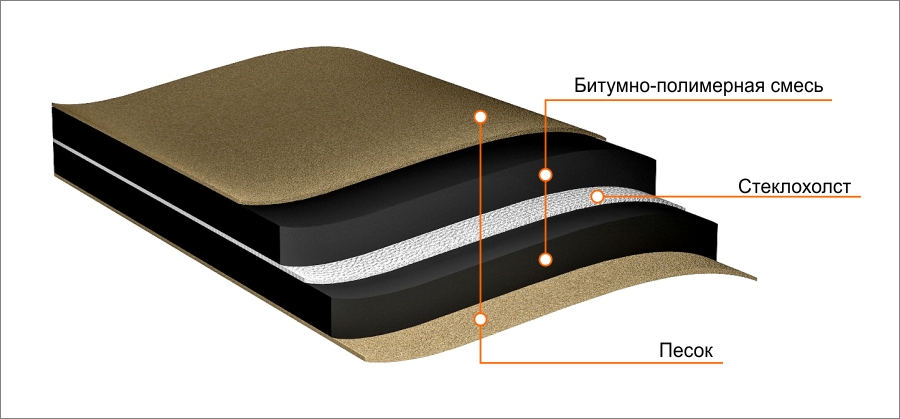

Lining carpet for ondulin or soft tiles is made based on fiberglass or polyester fabric... The basis impregnated with a mixture of bitumen and polymer resins. In terms of its structure and composition, the material resembles roofing material. However, it is more flexible, plastic and provides high waterproofing.

Distinguish 4 categories roofing underlay.

- Weldable - to fix it on the crate, the material must be warmed up. In this case, the lower bitumen layer of the web is melted and glued. This option guarantees strength and durability, but is very inconvenient, especially on roofs with a steep slope.

- Classic - not self-adhesive. The canvas is laid on a special bituminous glue. Then the fasteners are duplicated with staples or self-tapping screws. Fasteners are used only galvanized.

- Combined - from the seamy side, the material is covered with a layer of glue. The upper part of the canvas is fixed on nails. The bottom is glued.

- Self-adhesive - a layer of glue is applied on the seamy side of the canvas. As they are being laid, the protective film is removed from the roll fragments, rolled out along the crate and pressed. Minus: at temperatures below + 10 ° C, it is recommended to warm up the glue layer, which greatly complicates installation.

Materials released rolls 1 m wide. The characteristics of the carpet depend on the manufacturing technology. The parameters indicate on the packaging of the products.

Criterias of choice

Carpet for ondulin or shingles are chosen taking into account the following parameters.

- Manufacturer - whichever option is needed, it is worth buying a product from a trusted manufacturer. Poor quality material does not provide waterproofing. This is especially noticeable in the attachment points and in areas subject to increased stress.

- Tilt angle - it is practically impossible to fix the weld-on carpet on slopes with a large slope. Here, preference is given to the traditional version - on nails. With a small slope, a weld-on or self-adhesive carpet is much more convenient.

- Weather - with a high level of precipitation, it is better to take a weld-on lining. When solidified, the lower layer of bitumen polymerizes, which provides higher waterproofing properties.

Features of installation of underlayment under tiles

In a continuous crate between the plywood and the boards, they leave ventilation gaps of 2-3 mm... Otherwise, the air circulation will be insufficient and the wood will begin to mold.

- Preparatory work includes sealing difficult areas... Here, the flooring is done earlier. The entire canvas is laid on the valley. In this case, the material is leveled so that there is a strip of the same width on each side.

- Close up the area around the ventilation holes and chimneys. To do this, take a piece of a classic lining carpet, cut a hole in it of the required diameter and fix it on nails. It is recommended to fasten it not with nails, but with strips.

- Holes for wires and antennas equipped with rubber seals.

- If the underlay is only partially installed, the next step is decking along the eaves and at the ends of the roof. The canvas is laid over the entire width of the departure. The strip deep into the roof must reach at least 60 cm.

After embedding complex areas, proceed to the general flooring.

Laying on solid sheathing

- The crate is advised chalk, especially if there is not enough experience in construction. This will make it easier to lay the canvas flat.

- Stack the material parallel to the cornice, so that moisture drains from the surface and does not stagnate. Installation starts from the bottom.

- Cloth when laying stretch as much as possible, to avoid bumps and air bubbles.

- If using a classic underlay carpet, attach it galvanized nails. Fixation step - 20 cm.

- The second sheet is placed with with an overlap of 10-15 cm... Secure with self-tapping screws again. The joint between the canvases is coated with bituminous mastic or an adhesive roofing compound.

- Canvas reach the ridge and overlap it by 5 cm... Cut off the excess, if any, then attach this edge or glue it.

- From the side of the ends, the material is not fixed on nails, but wooden planks.

After the carpet has been laid, check the tightness. If everything is in order, shingles can be installed.