Wooden floor, wall panels, window frame or door frame need to be sealed. But the usual means for such products are not suitable: the tree changes in volume under the influence of temperature and humidity. For sealing joints in wood sheathing or floorboards, a composition is needed that would also change in volume or compensate for the changes.

Description and properties of cork sealants

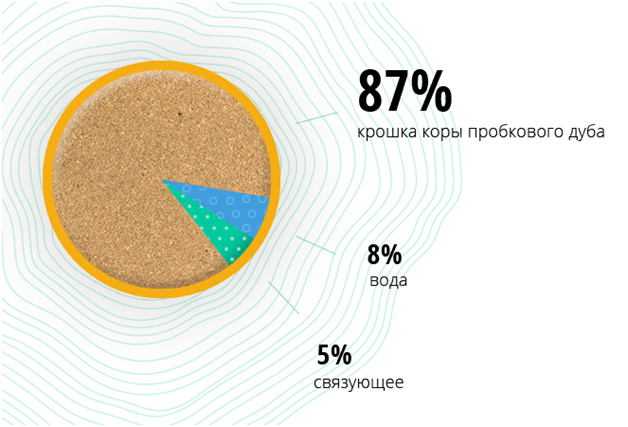

The crumb makes up 80% of the mass of the mixture, the proportion of the binder is 5%, and the proportion of water as a diluent is 8%. The material is considered environmentally friendly.

Liquid sealant replaces all known devices for sealing joints, cracks and chips in wooden floors or cladding. Previously, glue with a filler of fine wood chips was made for such purposes. Large gaps were filled with wooden inserts and onlays, and putty.

Cork joint sealant is much more convenient. It is a viscous substance that fills cavities and cracks well, and does not differ in appearance from wood. The composition does not need to be painted, sanded or compacted.

Scope of application

Liquid cork sealant suitable for sealing joints and crevices in any cork or wood products: panels, boards, parquet, substrate. In addition to wood, such a composition you can process concrete, glass, plastic, ceramics, metal... The material has high adhesion and is used in all cases when it is required to insulate or soundproof a structure.

- sealing of interpanel joints and seams;

- sealing assembly seams when installing doors and windows;

- compensation - when laying floors on a concrete screed, for example

- sealing joints in panel frame houses;

- sound insulation of interior partitions and interfloor ceilings - in the latter case, inserts and panels are more often used;

- the formation of sealing contours - here the cork composition plays the role of a joint filler and sealant;

- assembly of heat-insulating systems;

- finishing of floors - used when laying parquet, tiles, laminate, installing skirting boards, during repairs, when installing black flooring in order to eliminate squeak.

Cork sealant is used for indoor and outdoor use.

Application instructions

The sealant application technology is quite simple. You must strictly follow the instructions.

- Contact surfaces are cleaned of dirt, dust, greasy stains.

- Prepare instruments: sponge, spatula, closed-type pistol.

- Seam edgesto be repaired pasted over with masking tape.

- Put on the tube with the composition gun attachment... Bring the nose to the joint and carefully fill the seam with the compound... If the cavity is wide, the sealant smooth with a spatula... They also remove the excess.

- Continuously fill a gap 1-1.5 m long, then stop and remove the excess. In this case, the spatula must be periodically moistened with water.

- Sealant must dry completely... Depending on the humidity and temperature in the room, this will take 1-2 days.

Seams are sealed at a temperature not lower than -5 ° C.

Errors and their elimination

In order for the liquid cork sealant to serve for a long time, the following recommendations must be followed.

- Surfaces and seams must be degrease. If this is not done, the adhesion of the composition drops noticeably and the material is not retained in the cavity.

- Equalize mass need on the base, which is lower in level. Otherwise, the material does not hold tightly, a gap appears.

- Excess must be removed immediately. The "liquid cork" dries up slowly, but the solidified mass is very firmly fixed.

- Old cured sealant removed mechanically... It is impossible to dissolve the mass.

If the sealant is used to seal parquet chips, the shade must be carefully selected.