Traditionally, drywall is installed on the crate. The elements of the supporting frame are joined by connecting parts that give the desired size and shape. They produce a different-caliber profile for drywall, the sizes and types of which depend on the type of construction. There are elements for cladding the ceiling, walls, construction of free-standing partitions.

- Plasterboard profile material

- Types of profiles and their purpose

- Ceiling profile

- Ceiling guide profile

- Profiles for the construction of partitions

- Arched profiles

- Optional accessories

- Fastening fittings

- Disadvantages of using a wooden profile

- Rules for choosing profiles when buying

- Calculation of the profile for work

- Guides on the ceiling and walls

Plasterboard profile material

Uses a variety of metals, of which the most common are aluminum and galvanized steel... Both types prevent corrosion and therefore extend the life of the elements.

Aluminum the material is expensive, but possesses useful qualities:

- durable, lightweight;

- does not rust even after being damaged;

- tolerates frost and heat.

Galvanized metal also does not require preliminary processing before installation, it is easily assembled according to the standard scheme. Anodized zinc film protects against corrosion. The damaged layer on the surface becomes a problem if the framework is operated in a humid or reactive microclimate.

The transverse dimensions of the products and the thickness of the walls matter, since the drywall carries a certain load that the frame must withstand.

Types of profiles and their purpose

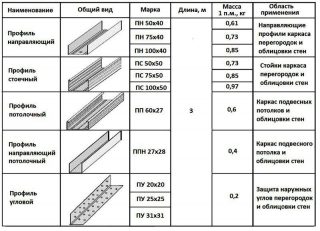

Domestic designation is different:

- MON - strapping profile along the perimeter when installing the partition frame (CW);

- PS - rack elements (UW);

- PP - ceiling moldings for sheets of g / cardboard (CD);

- Tnp - metal profile for fixing the ends of the ceiling profile (UD).

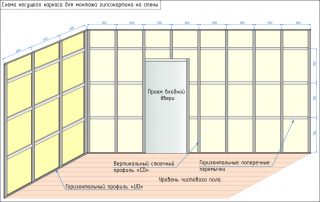

Before work, the installation sites of the longitudinal and transverse elements are calculated. If furniture is attached to the wall, heavy objects are hung, reinforced profiles are used.

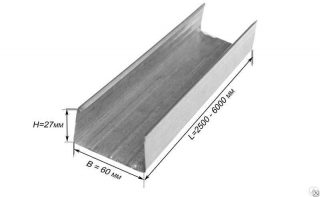

Ceiling profile

Dimensions of PP profile (CD):

- the length is produced in the range of 2500 - 4000 mm, the most running ones are 3000 and 4000 mm;

- base width - 60 mm;

- side shelf in height - 27 mm.

During installation the ends are brought into the harness from the guiding element along the perimeter of the walls. Fix to the ceiling with hangers (staples) so that in the end you get a flat plane in a single level for installing sheet material.

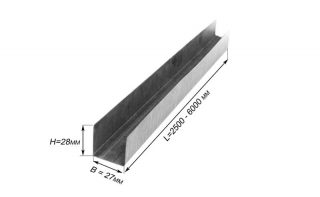

Ceiling guide profile

Dimensions of the guide metal profile (UD) for fixing longitudinal ceiling profiles:

- length of products 3000 and 4000 mm;

- side height - 28 mm;

- base width (to the wall) - 27 mm;

- metal thickness is 0.4 - 0.6 mm (depending on the manufacturer).

For wall decoration, such elements are fixed on the ceiling, floor and walls, while taking care of the verticality of the line drawn between the corresponding points above and below. In UD, a CD profile is installed in order to obtain a flat plane for fastening the gypsum plasterboards. Sometimes, to increase the bearing capacity of the lathing, products of the W group are used.

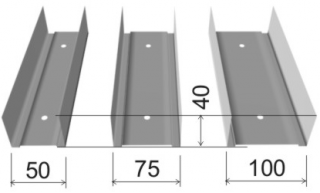

Profiles for the construction of partitions

UW Model put as a strapping on the floor, ceiling, adjacent wall to increase the rigidity of the racks. The strips serve as a guiding element to install a vertical profile for the gypsum board, whose sizes vary:

- molding length - 3000 and 4000 mm;

- base width 50, 65, 75, 100 mm;

- side height - 40 mm;

- metal with a thickness of 0.4 - 0.6 mm.

- length 3000, 4000 mm;

- width repeats the size of the strapping - 50, 65, 75, 100 mm;

- the side part is 50 mm.

Each element along the entire length is provided square H-shaped holes... They are designed for laying communications (wires) through partitions.

Arched profiles

Dimensions (edit) plasterboard profile:

- concave models allow to provide a radius of 500 - 5000 mm;

- convex put on radii 1000 - 5000 mm.

Long arched options are produced 2600 - 4000 mm... The ends of the profiles are also fixed in strapping strips to ensure the strength of the fastening as a base for the arch.

This category of structures also includes the wavy bends of a multi-tiered plasterboard ceiling. They use arched profiles to design rounded elements.

Optional accessories

Other optional accessories:

- two-level docking element sold unfolded, then bent in a U-shape, used for joining perpendicular racks;

- crab used for cross connection of CD profiles;

- straight suspension for ceiling and wall girders in the form of a perforated longitudinal plate, which is bent in the form of the letter P;

- anchor to lower the plasterboard ceiling, set if the suspension is not sufficient in length;

- extension for joining bearing elements.

There are corner fittings for purlin assembly that do not form a cross joint. You can do by trimming the profile shelves, while the resulting tongue is fixed with self-tapping screws.

Fastening fittings

To fix the racks and guides to each other, the installation of sheets requires hardware of a certain type. Metal parts are attached to each other self-tapping screw "flea" or "bug"... These hardware 11 and 16 mm long have a convex head and self-tapping thread. Convenient in that you do not need to pre-drill a hole.

Other types of fasteners:

- Self-tapping screws for metal with fine thread length 25 mm. They are used for mounting sheets of g / cardboard to a metal surface. The length of 45 - 60 mm is taken if 2 sheets are installed at the same time.

- Self-tapping screws with additional press washer. Produce piercing and drilling types, used for any opetany of materials.

- Ceiling wedge anchor... Set when fixing anchor-type suspensions.

Plastic dowels with a drive-in or screw-in self-tapping screw (take a length of 25 - 40 mm) is used to fix it in a floor slab or wall.

Disadvantages of using a wooden profile

The tree has disadvantages, in comparison with the galvanized profile:

- requires impregnation with linseed oil or other antiseptics, fire retardants against fungus, wetting, fire;

- does not always meet the strength requirement;

- the slats need to be taken dry, which are difficult to find on sale, or the purchased wet material must be dried for a long time;

- the bars have a curvature, so it is difficult to place them in a plane.

Galvanized girders differ in standard length, so their number is much easier to calculate. The material does not burn, does not change shape under the influence of moisture.

Rules for choosing profiles when buying

They acquire a variety that is suitable for the design; experts do not recommend changing products from one marking to another.

Product inspection rules:

- traces of rust are unacceptable;

- the thickness is checked with a caliper, it must comply with the manufacturer's standard;

- a barbed profile indicates low quality;

- the end should not be bent and crumpled;

- it is better to take perforated profiles where there are holes;

- check the manufacturer's declared length.

Calculation of the profile for work

Approximate material requirements standard:

- CD profile... For a single-level lathing, take 2.9 r.m. per 1 square of the surface. A two-level frame will require 3.2 l. M per 1 m2.

- UD profile count along the perimeter of the wall for the frame in one tier. The value is multiplied by two, with a two-tiered metal frame.

- Partitions. The UW profile for individual partitions is taken 0.7 l. M per square of the frame, and CW is considered 2 l. M per one m2.

- Reinforced wall cladding with lathing. The UW profile is calculated at 1.1 p.m. per square of the wall, and the CW profile is taken at 2.0 p.m.

Guides on the ceiling and walls

For ceiling length of guides count so that they put on top of all four walls... If the ceiling has protruding parts, the profile is mounted Around them in a circle or in the form of a rectangle. On the walls, guide strips are additionally placed around window and door openings, ventilation vents.

During installation free-standing partitions guide strips are installed along the perimeter of the future wall. To do this, they are calculated by the length of the partition, multiplied by 2 (floor and ceiling). Also take into account the intersection of the partition with the existing wall (in height), where the guide profile is also mounted. If the partition is installed between two walls, then the guides on both sides are taken into account.