Structural sawn timber is made for a more technologically advanced construction of one-story houses. Profiled beams are made of solid wood, so the walls of the house from natural materials create a comfortable microclimate for living. The peculiarity of the construction is that the wall joints do not require caulking.

Description and production of profiled timber

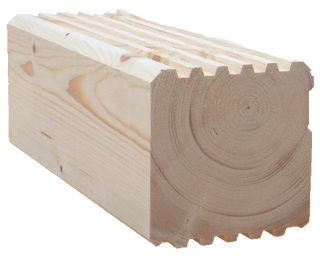

Configuration features:

- the outer side, which faces the street, is made in the form of a semi-oval or flat, bevels are removed on some varieties;

- inside the bar has a flat surface, it is planed during production;

- the upper and lower sides are milled so that there is a spike and a corresponding groove for joining;

- in some types of timber, strips of insulation are installed in the groove;

- the cross section can be of different shapes.

Release four types of timber. When sorting, the condition of the material is taken into account, especially for the core, attention is paid to the area of biological damage, stains, and the number of cracks. Knots are not considered defects and do not play a role in sorting.

Manufacturing manufacturing processes:

- the barked log is cut and sawn into its constituent elements, the bar is cut out from the central part;

- planing give it a rectangular, square or rounded section shape;

- the semi-finished product is fed to the milling equipment, where ridges and grooves of the desired type are formed, they are performed from above and below along the entire length;

- further, the technology assumes chamber drying or in vivo.

For production, a high-tech line with four-sided planing equipment is used. The machines are equipped with profile cutters.

Varieties of material

Shaped timber with grooves make cross-section: 100 x 150 mm, 200 x 200 mm, 150 x 150 mm, 150 x 200 mm. After sharpening and profiling, the lumber has an attractive appearance.

Variety is produced depending on section type:

- Finnish. It features two protruding teeth and an internal platform for installing an insulating strip. In this way, profiled or glued beams are made; in any case, dry raw materials are taken for production.

- Comb. The top and bottom of the profile are made in the form of thorns (from three). A wall made of such a building material is not blown through even with strong gusts of wind, moisture does not get inside the joint. The peculiarity is that during construction it is not necessary to install an internal groove insulation. This reduces construction costs.

- Scandinavian. It is an improved view of the comb profile. The drawbacks have been eliminated in the product, so this section is more convenient. A wide platform for the installation of pins is provided, and the height of the studs is increased to 12 mm. The cross-section is made in the form of a trapezoid. Use a material of natural moisture.

- German. The shape of the protrusions and depressions allows for continuous joining after a short service life.The shrinkage of the log house leads to jamming of the labyrinth system, so the wall plane cannot be disassembled. There are 4 - 6 grooves on the edges. It is better to take material made from dried raw materials.

- Profiled mini bar differs in cross-sectional dimensions: element thickness 45 mm, width 145 mm, bar length 6 m.

By manufacturing technology distinguish between:

- timber of natural moisture;

- chamber drying material.

The first category includes a bar that before sawing and profiling dried naturally. The material is stored in stacks with air circulation. This drying takes about 1 year and is an uneconomical method. From the point of view of technology, a bar of natural moisture has its advantages.

With the chamber method, the moisture content of the workpieces is reduced with dryers... The production time of the material is reduced, since the chamber processing quickly reduces the moisture content of the wood. The process lasts 2.5 - 3.5 weeks, the time depends on the size of the cross section.

Areas of use

The walls of the house are not the only option for using profiled beams. The material is needed for other structures at home.

Use cross-sectional dimensions:

- external load-bearing walls - section 200 x 200 mm;

- internal partitions and walls - 100 x 150 mm;

- Mauerlat in the roofing system - 100 x 150 mm, 150 x 150 mm;

- roof rafters - 100 x 150 mm;

- floor beams - 200 x 200 mm.

In addition, spans of large halls for sports, trade, entertainment, vaults of pools and water parks are being erected from a bar. The material is used in the construction of bridges. Natural wood walls create the required microclimate in warehouse buildings.

House projects

Bath projects

Profiled timber manufacturers

There are about 40 manufacturers in Russia profiled timber, the company also produces other products of the sawmill industry.

- LLC "Les Company" manufactures timber and ready-made house kits. The production is located in Yaroslavl.

- ZAO 78 DOK N.M. manufactures and sells profiled timber, offers construction services. Located in Moscow.

- Voskresensk woodworking enterprise produces profiled timber and other sawn timber. Located in the city of the same name in the Moscow region.

- Company "Karelia Wood" is engaged in the manufacture and sale of natural moisture timber and chamber processing. Located in the city of Kubinka, Moscow region.

- Construction and production company Ro-Stroy located in Kirov. Sells solid wood lumber.

For construction, they choose products from well-known manufacturers who have worked in this field for many years.