The professional sheet is used as a roof covering, facade decoration. Fences are erected from the material, fillings are made between the elements of frame buildings, internal partitions. Each type of profiled sheet differs in the shape of the profile, the height of the wave, and therefore has certain characteristics. Profiled sheet MP 20 is one of the most popular types, which is often used in construction.

Material description

Profiled sheet with the designation MP 20 is the same as C 20. In the first case, the coating is produced by the Metal Profile enterprise in Lobnya, and the second combination is used by other manufacturers who also produce the profiled sheet MP20. A variety of rental options and low cost allow it to be used in various fields.

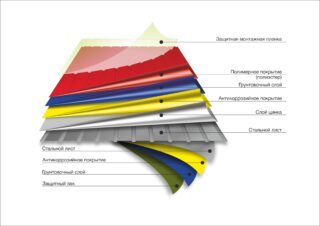

The profile gets its properties depending on the metal in the base. Galvanized corrugated board C20 is a material of several layers, the number of which varies from 3 to 10. The qualities of the profile depend on the structure of the films and their thickness.

Film coating technology is regulated by documents:

- TU 141.46.95 - 1989, GOST 149.18 - 1980, where the standards for the manufacture of cold-rolled steel with galvanized oxide film are prescribed;

- TU 141.47.92 - contains recommendations regarding galvanized metal with a polymer layer;

- TU 141.12.47 - 1988 - technology of applying aluzinc film;

- GOST 24.045 - 94 - composition and requirements for paint and varnish coatings;

- TU 11.220.01.525 -2003 - quality indicators for powder coating.

Profiled sheet MP 20 contains galvanized metal with an oxide film on both sides. An increase in the number of other layers leads to an increase in useful properties and an extension of service life. The outer coating differs in texture and color. The surface has the appearance of natural stone, brickwork, wood, it can be matte or glossy.

Manufacturing and painting technology

The metal profile MP 20 is made of rolled steel, which already has a colored coating. Protection is applied on technological conveyors, while attention is paid to the quality of performance, since the film can be destroyed during the stamping process. On the finished profiled surface, paint is rarely applied due to the complexity of the shape.

Manufacturing includes the following stages:

- galvanizing ferrous metal to increase moisture resistance;

- creation of an oxide film on the surface;

- treatment with a primer to increase adhesion with subsequent layers;

- polymerization with compounds, varnishing;

- protective coating with a special film.

Galvanizing is done by passivation using anodes or cathodes in an electrolyte solution. Here zinc reacts with different melts, resulting in an oxide film. The barrier protects the metal from rust and destruction.

The decorative polymer coating is 25-200 microns thick, in a thick layer they make relief embossing under the texture of wood and stone. The back of the profile is covered with a resistant varnish. The paint and varnish layers are applied by continuous rolling of a galvanized roll on an automatic line. After that, the painted steel is transferred to stamping, chopping, and pulling conveyors.

Requirements for a protective polymer barrier:

- fast solidification, resistance to pollution;

- good adhesion to the galvanized layer;

- flexibility, elasticity, scratch and abrasion resistance.

Automation reduces material costs by 25 - 40%. On mechanized lines, paint can be applied from both sides or only from the face.

Positive and negative properties

The dimensions of the MP 20 corrugated board allow you to mount the sheets without the use of special lifting equipment. Profiled products are lightweight. A few assistants are enough to install the panels in the installation position.

Other useful characteristics

- A reinforced frame is not made under the sheets, since the wall decoration from C 20 profiled sheet does not overload the wall. They also do not care about strengthening the foundation, and the cladding is placed on old buildings.

- Any length of profiled sheet strips can be ordered, so the roof is covered along the length of the slope without joints. This method allows you to avoid leaks at the joints, the work is accelerated.

- Flexible material is used for complex structures. The professional sheet will last from 25 to 50 years, depending on the type of polymer barrier on the sheet surface. The corrugated board will not rust, will retain its color and shade for a certain time, and will not deform.

- The panels do not develop harmful microorganisms, mold, moss.

- Large selection of colors and textures for various natural materials, attractive appearance.

The disadvantage of a metal profile is that it conducts sound well. Therefore, raindrops and birds produce a “drum effect”. They fight this phenomenon with noise insulation, which is installed together with the coating.

Galvanized corrugated board MP 20 1100 0.7 can only be used on slopes with a large slope, since on other roofs it will not withstand the additional load from snow.

When cutting, the seams are immediately painted with special compounds from a spray gun so that corrosive processes do not start. For the same purpose, the welded seams to the supporting frame are additionally protected from moisture by painting. For welding, use sheets with a thickness of at least 0.8 mm.

Scope of use

Unlike other brands, which are used in any form for the facade and roof, MP20 corrugated board is produced in three versions. Each is designed for its own area of use.

Modifications of the MP 20 brand:

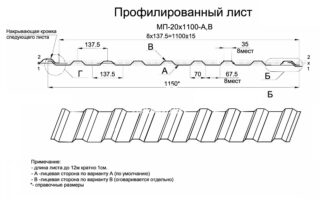

- Type A and B. Designed for the manufacture of fences, fences, they are placed as filling between posts made of brick, stone, steel, concrete. This type is always used on the profile surface by default. Trapezoidal ribs are evenly spaced 137.5 mm. The ridge has a top width of 35 mm, between them a lowered section of 67 mm.

- Type R. They are used for roofing works. The ridge is 67.5 mm wide, the pitch between the waves is 35 mm. Has greater strength compared to marking A and B.

Decorative profile options are used for the facade. Often the basement is made with a corrugated board with a pattern of masonry; a brick pattern is also used for the lower part of the building. Such a pedestal of the house inspires a sense of the solidity of the structure. For walls above the basement, a pattern of wood, brick, leather is used. Plain sheets with various colors according to the RAl catalog are placed on the roof.

Material appearance

Decking MP 20 is produced with a profile height of 20 mm. The size of the trapezoid on both sides is different due to the inclination of the side walls. Some manufacturers produce products with a corrugation height of 18 mm, despite the declared labeling.

Kind of corrugation:

- For wall applications, sheets are made with a wave without a roofing groove on the ridge and the color will be on both sides.

- Roofing metal profiles with the designation of the letter R are produced with a gutter on the crest of the wave for water drainage, and polymer protection is made only on one side.

- Variants with semicircular waves, with a pair of rectangular protrusions stamped between them, such a profile has an original appearance.

- The corrugated roof sheeting is equipped with a capillary gutter, pressed along the lateral border of the sheet at the point where it overlaps with another element on the roof to drain condensate during the operation of the coating.

The main colors for the MP 20 brand are: 9003 signal white, 6005 moss green, 8017 brown chocolate, 3005 red wine, 8019 brown-gray, 7024 graphite gray, 1015 light ivory.

Specifications and dimensions

The R-marked roofing version is most popular in a thickness of 0.5, with an optimal ratio of cost and quality.

Performance characteristics:

- overall width from edge to edge - 1150 mm, working, taking into account the overlap - 1100 mm, the lock takes 50 mm;

- the length can be ordered from five to twelve meters, but builders do not recommend using sheets larger than 4 - 5 meters for ease of installation.

The thickness of the zinc layer on the surface of the sheet plays a role. There is a thin galvanized material with a weight of less than 100 g / m². Such a metal profile is used for temporary structures, since it is the zinc oxide film that protects against rust.

The recommended zinc layer on the metal surface should be in the range of 140 - 275 g / m². Accordingly, there is a difference in price between types of metal, therefore, before purchase, they are determined for the purpose of use.

Classification of profiled sheets MP 20 by type of coating

Varieties of polymer coatings:

- Acrylic. The coating works for a long time, but after a few years it fades and fades. The layer thickness is 25 microns, the film is easily damaged. Such sheets are installed on temporary buildings.

- Polyester. The second budget option with a similar thickness of 25 microns. The additives increase the sun resistance, so less fading. The strength is low, easily scratched, erased.

- Plastisol. Contains PVC and modifiers. The thickness of 200 µm allows surface embossing. Durable coating, used in chemically contaminated conditions.

- Pural. In production, polyamide is combined with polyurethane, resulting in a reliable and durable material. It does not degrade in conditions of heat, frost, it is used on the seashore in conditions of increased insolation.

The most reliable of all layers is considered to be a polydifluorionate coating. An effective coating does not react to harmful chemicals, alkalis, acids in the atmosphere. Differs from other coatings in high cost.