Profiled sheet C 10 is one of the options for rolled metal used in private and industrial construction. The material has all the advantages of metal coatings and a number of features.

Description of corrugated board C10

C10 corrugated board is a type of facade or wall material. It is intended for decoration of walls and facades from the outside, construction of fences and gates, as well as for sealing walls in garages or cabins.

A distinctive feature is the profile height. It is only 10 mm. Such a relief is not very suitable for draining water on inclined slopes, therefore C10 is rarely taken for roofing. However, a special grade C10 is produced with a groove for water drainage. This option is marked with the letter R.

C10 is less popular than, for example, C8, since it is produced only by single factories. It is mainly used in industrial construction.

The characteristics of the C10 profiled sheet depend on its type and manufacturing method. They are distinguished by the type of coverage.

- Galvanized corrugated board - the steel sheet of the workpiece is loaded into an electric bath. The entire surface is covered with a layer of zinc. The thickness of the layer depends on the purpose of the material and the conditions of its use and is regulated by GOST.

- Polymer coated sheet - usually combined with a protective zinc layer. Polymer paint makes the material attractive and protects steel from ultraviolet radiation and moisture. The color palette of polymer paint is very large, so it is easy to choose the required shade of rolled metal.

Depending on the method of applying paint and varnish, 2 categories are distinguished.

- C10 corrugated board with one-sided coating - a layer of polymer is applied only to the front side of the material. The back metal is protected with a layer of varnish. The material is allowed to be used for wall cladding. Its price is less.

- Option with double-sided coating - a layer of pural or polyester is applied to the sheet on both sides. It is more often taken for the construction of fences and gates.

A double-sided profiled sheet with a curly edge is made especially for fences. The edging has an attractive appearance and is protected by a layer of paint.

Advantages and disadvantages

Profiled sheeting C8, C10, RN20 has many common advantages:

- The metal profile is made of very thin steel, which provides a low cost.

- With a small thickness, the C10 profiled sheet has a very high bending strength and easily withstands wind and snow loads.

- Steel is completely insensitive to high and low temperatures.

- The weight of the sheets is small, which greatly simplifies transportation and installation.

- Rolled metal products are available in different colors, which makes it easier to choose.

Cons of material:

- Metal does not retain heat at all, so it is as cold in a steel box in winter as it is outside.

- Profiled sheet does not provide sound insulation, on the contrary: metal amplifies the sound of rain.

Since the material does not shrink, rigid fasteners are allowed.

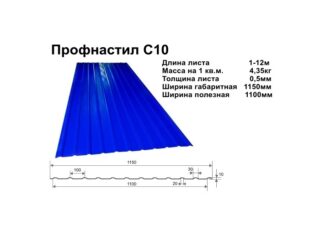

Specifications and dimensions

- Length - from 50 cm to 8 m. Sheets up to 12 m long are also available.

- The width of the C10 corrugated board is 100, 110 and 125 m.

- Profile height - 10 mm.

- Sheet thickness - 0.3, 0.4, 0.45, 0.5, 0.55 mm. C10 professional sheet with dimensions of 0.3 and 0.4 mm belongs to the economy class. They are allowed to be used for the construction of fences in areas with low wind load. According to GOST, the thickness of the facade cladding is 0.45–0.55 mm.

The weight of 1 m² of rolled metal depends on the thickness of the product and its dimensions.On average, the mass ranges from 4.65 to 6.49 kg.

The physical dimensions of the C10 profiled sheet are indicated on the package. However, its usable area is less. Sheets are laid and fastened with an overlap, while part of the area is lost. If the total width of rolled metal is 100 cm, then its useful width is only 90 cm. These data are usually also indicated on the packaging.

The technical characteristics of the C10 profiled sheet correspond to its main purpose - wall cladding. The load-bearing capacity of the material is low.

Decoding of marking

The marking indicates all the necessary characteristics of the C10 profiled sheet: dimensions, wave height, type of material.

- the first letter - "C", indicates the type of material - wall metal;

- 10 - wave height in mm;

- the number 900 and more indicates the useful thickness of the sheet;

- the last number indicates the thickness.

When choosing, you need to find out the thickness of the zinc layer. According to GOST, it ranges from 140 to 252 g / m². However, there are often products on the market with a layer thickness of no more than 100 g / m². This is not enough. Such material will last no more than 2-3 years.

Colors and finishes

- Without paint and varnish layer - the material has a natural zinc color - silver-gray. Looks good in a fence, suitable for wall cladding in an industrial workshop.

- Colored profiled sheet C10 with different sizes is covered with a polymer decorative layer. The color scheme corresponds to the RAL palette. The material is preferable for cladding facades, basements. Alternatively, you can paint it yourself.

The layer of polyester coating is usually smooth and can be matte or glossy. The pural layer can be thicker, which allows you to form an additional texture that imitates the pattern of wood or stone.