Builders appreciate versatile materials that can be used for a variety of purposes. Professional sheet H60 belongs to the group of products with the greatest bearing capacity. It is important to figure out where it is worth using it, and where the characteristics are redundant.

Description of products

Profiled sheeting N-60 belongs to the group of cold-formed sheet profiles with a trapezoidal corrugation and is used for construction purposes. Products are made of galvanized steel on roll forming machines.

To ensure the uniformity of characteristics and to prevent the circulation of low-quality products, all manufacturers are required to comply with the technical conditions approved by GOST 24045-2016.

According to GOST, it is impossible to change the dimensions of the H-60 corrugated board. The type of raw materials, sheet thickness, presence and color of painting may differ from the parameters.

Advantages of the material

The popularity of the H60 profiled sheet is caused by the multifunctionality of the application. Material advantages:

- Corrosion resistance. All products are made of galvanized sheets, in addition, a separate group of products has a paint and varnish coating.

- Strength. The quality is achieved by the structure - a stiffening rib is additionally stamped on the corrugations.

- Color variety. The color corresponds to the colors of the RAL line, which allows you to buy additional profiled sheet as needed to maintain a uniform style when building neighboring objects.

- Ease of installation. Installation does not require special skills and expensive tools.

- Resistant to temperature changes.

- Fire safety.

Some manufacturers give a guarantee against perforating corrosion for up to 40 years, and for paint fading up to 15–20 years.

Application in construction

Material properties make it suitable for manufacturing:

- fixed formwork for pouring reinforced concrete floors;

- interfloor ceilings on which the topcoat is laid;

- roofs of warm multilayer and cold roofs;

- reinforcing partitions in frame buildings;

- external walls of industrial and utility buildings;

- temporary and permanent fences.

It is not always wise to use the material in construction. For example, when making temporary fences or home sheds, it is better to use cheaper modifications of corrugated board.

Production of professional sheet Н60

Raw materials for production are rolled galvanized sheet steel for cold forming (CP) or for tempered painting (PC), produced in accordance with GOST 14918.

In general, the profiled sheet must correspond to the first class of zinc coating in accordance with GOST-52246.

For temporary products with a service life of up to 10 years, it is allowed to use products with a class of galvanized coating No. 2.

It is allowed to use imported steels that comply with GOST 14489 in terms of characteristics.

During production, galvanized metal sheet 1250 mm wide is fed into a roll forming machine, which gives the workpiece a ridge shape. Then the guillotine cuts segments in multiples of 250 mm.

Requirements for technical characteristics

- geometric dimensions;

- the thickness of the metal;

- method of painting.

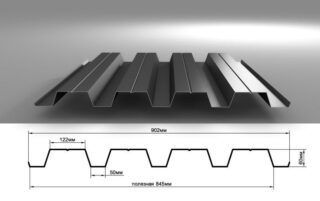

The characteristics of the three modifications are summarized in the table.

| Brand | Thickness, mm | Full width, mm | Working width, mm | Weight 1 m / p | Weight 1m² |

| H-60-845-0.7 | 0,7 | 902 | 845 | 7,4 | 8,8 |

| H-60-845-0.8 | 0,8 | — | — | 8,4 | 9,9 |

| N-60-845-0.9 | 0,9 | — | — | 9,3 | 1,1 |

The length of the sheets is determined by the manufacturer or customer. GOST provides for the manufacture of parts with sizes from 3 to 12 m.

All information necessary for the developer is given in the product labeling. There are 6 groups of alphanumeric code in the full symbol:

- Profile type that determines the purpose and height of the corrugation. H - load-bearing, NP - load-bearing for reinforced concrete floors, NK - roofing decks, C - wall and enclosing. НС - for bearing and enclosing structures.

- Dimensions in mm: height, assembly width, thickness.

- Group and grade of steel used in production.

- Front side type and color.

- Back side type and color.

- Name of the standard.

An example of a symbol: Н60-845-0,7 St 3Ps Ts1Ts1 PE Ral 5005 / GOST 24045-2016. Explanation: bearing type with a corrugation height of 60 mm, working width 845 mm, sheet thickness 0.7 mm, made of steel grade St3Ps, type 1 zinc coating on both sides and painting with polyester enamel on the front side, the product complies with GOST 24045.

Selection Tips

The price of a product cannot be decisive when purchasing a corrugated board. Only products manufactured in accordance with GOST will meet all the required parameters.

Characteristics to look for when buying:

- Compliance of products with GOST, confirmed by certificates. Products made according to technical conditions (TU) may differ in size and have a lower quality paintwork.

- The presence of coloring. Painted surfaces have additional anti-corrosion resistance and can be used for any building structure.

- The paint must be free from peeling and scratching. Dents and other defects are a reason to abandon a purchase or ask for a discount if the appearance is not significant, for example, for internal floors.

- The thickness of the sheets directly affects the strength of the finished building structures. Purchase the products provided for by the project.

The color scheme should be combined with the exterior of the neighboring buildings and the design project.

In different cases, they use corrugated board with a polymer coating or simply galvanized sheets. Consider the cost of products and operating conditions. For outbuildings and fences on private plots, painted products are chosen. For industrial buildings, it is sufficient to use the galvanized version.

Installation technology

Professional sheet H-60 is used for different purposes and the installation rules are different. In addition, material handling must be followed to maintain the manufacturer's warranty.

Delivery, unloading, storage

In order to deliver the professional sheet to the place of work without loss of quality, follow the recommendations:

- the design of the transport must ensure unhindered top loading;

- packaging of sheets should be 15–20 cm shorter than the body - sheets should not hang down during transportation;

- travel speed - no higher than 80 km / h;

- packaging should exclude the movement of sheets in a pack relative to each other during acceleration and deceleration.

Unloading of bundles in their original packaging is carried out using lifting equipment with soft slings, and with a sheet length of more than 5 m, using traverses. When unloading manually, one worker should be 1.5–2 running meters, but not less than 2 people.

Removal of sheets from a pack is carried out by the lifting method, excluding displacement. Products should be carried in an upright position, avoiding bends along the corrugation.

Immediately after unloading, the packaging is removed, and protection against atmospheric agents is carried out with opaque materials. The sheets are stored in a pack for no longer than 6 months.

Cutting corrugated board with a paint-and-lacquer coating with a grinder leads to the cancellation of the warranty for the product. For cutting metal thicker than 0.7 mm, use an electric nibbler.

Construction of fences

The professional sheet is placed in a vertical or horizontal plane. In the simplest and least costly method, the H-60 profiled sheet is used, located in corrugations along the ground.

The frame is profile pipes dug into the ground with a cross section of at least 60x60 mm, an installation step of 2-3 m. The pillars are deepened at least to the freezing depth. Additional jumpers are not satisfied, but the profiled sheet is fastened with bolts or self-tapping screws to the racks. Hardware is placed in each corrugation.

The profiled sheet is subject to strong wind loads, therefore, they approach the arrangement of the pillars responsibly, shallow pipes will not withstand the load, the fence will tilt or fall.

For fences with a height of more than 1.5 m, the sheets are placed vertically. It is advisable to use professional flooring NS-60, its characteristics are sufficient to perform the functions of a fence, and the price is much lower.

Dug in and concrete pillars are connected by two or more horizontal bridges, the number of which depends on the height of the fence. On average, one crossbar is provided for 80–90 cm of the height of the filling web.

Walling

The metal profile is used for the construction of frame buildings, sheds, outbuildings.

Depending on the project, modifications N-60, NS-60, S-60 are used.

The frame is made of pipes of square or rectangular cross-section, it is possible to use a wooden beam.

Fastening is provided with bolted or roofing screws, which are equipped with a rubber or silicone gasket.

Arrangement of interfloor ceilings

Overlappings between floors using a profiled sheet are performed in two ways:

- The deck serves as a permanent formwork for the reinforced concrete floor.

- On top of the profiled sheet, logs are laid, serving as the basis for the finishing coating with boards, chipboard, OSB.

The calculation of overlaps with long spans should be carried out by specialized organizations.

Roofing use

In practice, two options for manufacturing a roof are used: without insulation and installation of a warm roof.

In both cases, work begins with the arrangement of the rafter system and the crate.

The rafters are placed at intervals of 70–80 cm. The use of H-60 corrugated board allows for a rare arrangement of lathing boards. It is enough to attach horizontal supports at distances of up to 2 meters.

The weight of the H60 profiled sheet has a significant load on the rafter system, it must be taken into account in the calculations.

To protect skates, profile fractures, abutments to walls, pipes and other elements, additional elements are acquired.

In the case of building attic floors or arranging a warm attic, the order of the layers in the "pie" will be as follows:

- interior decoration;

- vapor barrier membrane;

- insulation;

- waterproofing;

- crate;

- counter-lattice to provide a ventilation gap;

- corrugated board.

For convenience and acceleration of work, a sealant for H60 corrugated board is purchased.