A profiled sheet with a wave height of 44 mm is used as a material for supporting and enclosing structures. Professional sheet НС44 has letters in the marking, which speak of the versatility of its use. The products are produced with additional ribs on the crest of the corrugation and between the protrusions in the lower part. The products are distinguished by an acceptable cost, the material is gaining popularity due to its strength properties and a wide choice of options.

Features and scope

In terms of hardness and bearing capacity, professional metal is divided into wall, roofing and universal. The third type, which includes the HC44 corrugated board, differs from the other two types in the configuration of the corrugation at the same wave height.

NS-44 sheets are used:

- in the form of slab reinforcement of reinforced concrete floors;

- for arranging a flat roof with a slope of 7 - 12 °, as well as other roofs of houses and industrial buildings;

- for the installation of interfloor composite slabs in the form of floor panels;

- for filling gaps in the walls of frame buildings;

- for the construction of fences, fences, partitions, walls;

- for cladding facades of buildings.

Additional reinforcement elements are located in the upper parts of the corrugated protrusions and in the lower gaps. The ribs increase the hardness of the sheets, increase the strength indicators, and allow them to withstand loads from snow and strong winds. Grooves are made along the side edges of the strips to collect condensate and remove it from the roof.

The rigidity of the material allows you to save on wood for roofing or wall sheathing. The material only with a galvanized film is used in a non-aggressive air environment. In other cases, polymerized protection sheets are used.

Method of production of professional sheet НС44

Products are produced from steel coils by cold stamping under conditions of continuous movement on a roll forming conveyor.

Stages of manufacturing a profiled sheet, painted with polymer compositions:

- galvanizing metal on both sides, reproducing an oxide film on the zinc surface by the cathodic or anodic method in an electrolyte solution;

- priming the area of the sheets to increase adhesion, degreasing;

- applying a paint layer on flat metal surfaces;

- processing with a protective composition;

- bending by passing between the stamping rollers.

Automation feeds the rolled strip to the conveyor, where the metal moves to the guillotine (scissors), cut to the desired size, then stamped with a given waveform and required parameters. The rental takes place automatically, which reduces the cost of products by 20 - 40%.

There is an option for hot forming, but it is rarely used due to the preheating of the rolled metal, which increases the cost of production. Zinc passivation promotes the formation of a phase film when the metal reacts with melts. The barrier completely eliminates corrosion or significantly slows down its course.

Classification by the type of polymerized film layer

The coating on the surface of the products should quickly harden and bond well with the metal. The layer must be flexible, elastic, to bend without cracks and deformations, to resist abrasion.The paint is applied on one or both sides of the sheet, in the marking the letter A means the first option, and B - double-sided protection.

Types of polymer layers:

- Polyester is available in glossy or matte finish. The second type of coating has a rougher surface, captures ultraviolet light more strongly, lasts 2 - 3 years longer than the shiny layer. Both coatings are resistant to insolation and harmful substances in the atmosphere. The gloss reveals all the irregularities of the lathing, shows the flaws of the frame on the surface of the roofing and wall covering.

- Pural contains several types of polymers (polyamide, polyurethane). The coating lasts a long time without changing the original characteristics (about 50 years). The layer protects the metal from destruction, does not crack, does not flake off under load. Products withstand the action of atmospheric acids, alkalis, therefore it is used in the chemical industry for roofs and partitions in workshops.

- Plastisol. Produced on the basis of PVC with the inclusion of plasticizers and modifiers. The material burns out in direct light, so it is placed in the shade or lighter colors are chosen. More often the metal has an embossed surface for wood fibers or stone, brickwork.

The strongest is the polydifluorionate layer, which completely protects the base metal from destruction. Such a profile is expensive and therefore rarely used.

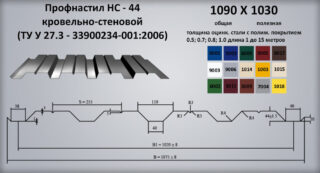

Specifications

Other material indicators:

- Base metal sheet thickness 0.6; 0.65; 0.7; 0.75; 0.8 mm. When determining the thickness, the size of the protective films is not taken into account, since they are measured in microns and do not affect the indicator.

- The weight of the strips. To find it, you need to multiply the square of the sheet by the mass of 1 m². The indicator depends on the wall thickness. The weight of one square of the НС44 profiled sheet is 6.6 - 9.4 kg.

GOST allows a deviation from the norm in the height of the corrugation ± 1.5 mm, from the declared length - by 10 mm, and the difference in width - ± 8 mm.

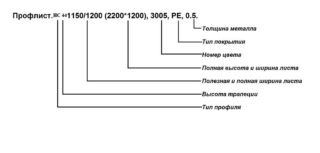

Abbreviated conventions and definitions

Meaning of other marking signs:

- the number standing in the field of the first letter indicates the wave height indicator;

- the second letter gives an idea of the wall thickness;

- the third speaks of the working size in the width of the sheet;

- the last number indicates the length of the strip.

There is a concept of common and useful width. It depends on the height of the corrugation, since each panel overlaps the adjacent one with overlaps in one corrugation. Bearing / wall profiled metal NS 44 is produced with a width of 1052 mm, of which 1000 mm falls on the worker, and 52 mm goes to the overlap of the corrugation during installation. The useful size is shown in millimeters, so that the coverage of the roof plane is immediately visible.

Life time

The time during which the material does not collapse depends on the type of the upper protective layer. The indicator is influenced by operating conditions and climate. Not all types of polymers in the composition of the protection are equally resistant to the action of harmful factors.

Timing difference depending on coverage:

- sheets with only zinc coating, without a polymer layer will serve for 20 years;

- the aluzinc coating will withstand without deformation for about 25 years;

- material with a polymer layer will last up to 50 years.

Also take into account the magnitude of the loads that will act on

a covering or cladding.

Profiled sheeting NS 44 is used not only for pitched, but also for flat roofs, therefore, the weight of the snow crust is taken into account when calculating. Also take into account various devices in the form of snow holders.

Selection Tips

Color is as important as load-bearing capacity and strength. For the walls of the facade, a material is chosen whose shade is lighter than the roof, so that the exterior looks organic. For fences, the inner side is taken lighter in order to visually expand the space of the yard.

When buying, they choose goods from well-known manufacturers, check the quality of the material. The sheets should have a uniform coating on the side and horizontal walls of the wave. If the length indicator is slightly different from that indicated in the documentation, it may not be considered a marriage, if the buyer has agreed to this.

The crescent shape of the stripes is checked on site. For every 3 meters, it should not exceed 5 mm with the length of strips up to 6 m. For a length of over 6 m, 1.5 mm is allowed for each running meter of the profile. Waviness on the surface of ordinary corrugations should not be more than 1.5 mm, and on the side edges - no more than 3 mm.

Installation features

For professional sheet NS 44, additional elements are used:

- on the roofs, cornice strips are used, special elements for decorating valleys, gutters, abutments to the cornice and protruding elements;

- for facade cladding, start and finish strips, internal and external decorative corners are set, a J-profile is used, sloping profiles for edging window and door openings.

It is better to use strips of such a length so as not to make transverse joints, but experts do not recommend buying a profile longer than 4 - 5 m. On the eaves overhang, the ends of the strips are set so that they fall into the middle of the gutter.

Sheets with a longitudinal or vertical arrangement of waves are mounted on the walls, respectively, the profiles are placed vertically or horizontally. Between the racks, panels of polystyrene, expanded polystyrene are attached, and the resulting gaps are sealed with polyurethane foam. If mineral wool is installed, they equip a counter-lattice in order to organize a ventilated gap for condensate drainage.