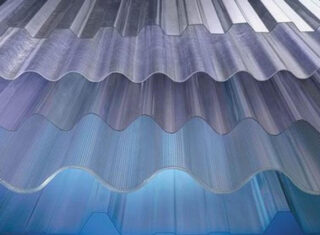

Under the concept of transparent slate is meant a relatively new building material. It has only a distant relation to the traditional asbestos-cement sheet - the wavy profile and shape of the product. Transparent products are widely used due to the use of different types of raw materials.

Scope of use of transparent slate

The use of transparent corrugated slate is very diverse. A functional coating makes any structure aesthetically pleasing. This is primarily due to its flexibility, which allows you to use panels for the following purposes:

- roofing material;

- creation of arched structures;

- arrangement of fences;

- awnings and gazebos;

- covering of terraces and verandas;

- protection of outdoor pools from wind, debris and UV radiation;

- covering of greenhouses, loggias.

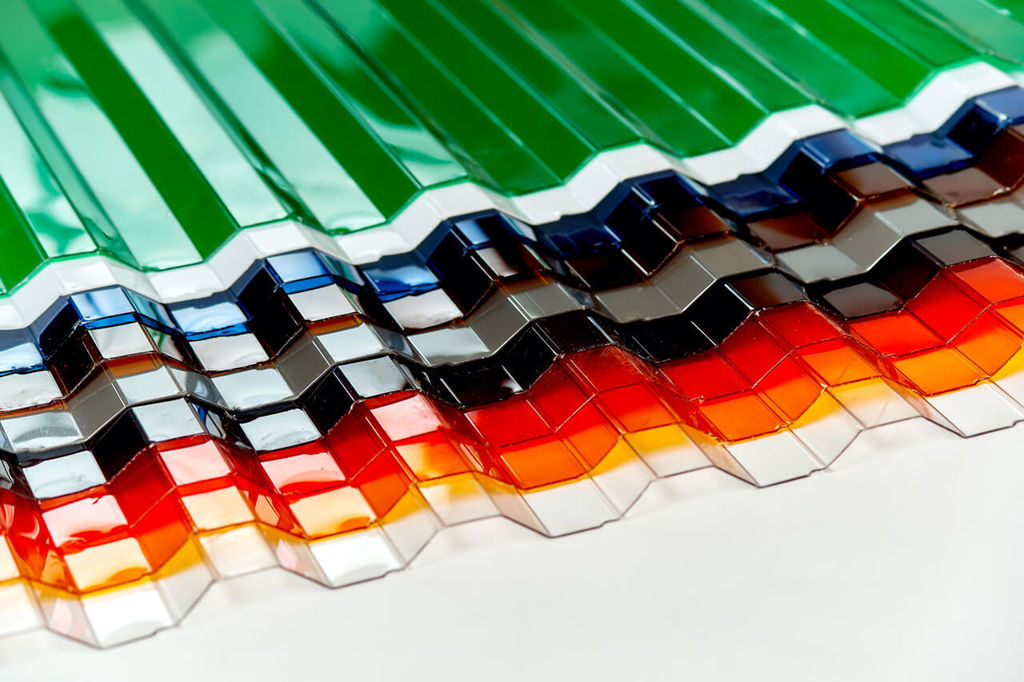

Material is made from various raw materials, on the properties of which the further use of sheets depends.

Materials for making

Slate production is based on four types of plastic - PVC, fiberglass, polycarbonate and acrylic plexiglass. The raw material influences the field of application, the cost of the final product and the processing technology.

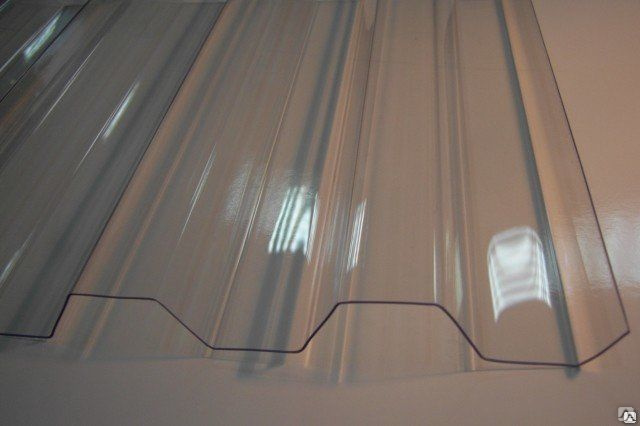

Polyvinyl chloride

For the manufacture of plastic corrugated slate used food materials... From all presented PVC raw materials passes the sun's rays worst of all, although this cannot be seen with the naked eye. A translucent material is often used for arranging the roof of a winter garden and greenhouses.

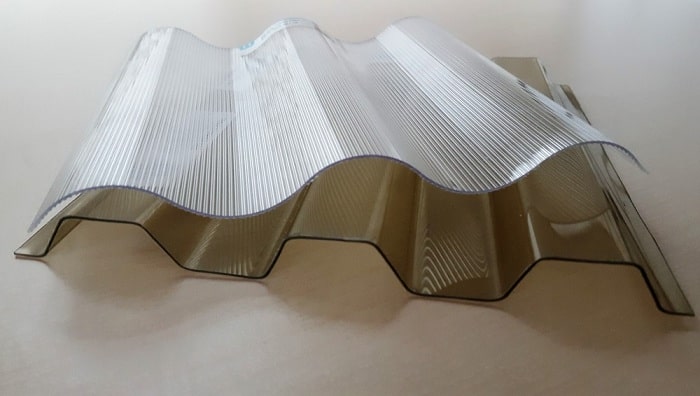

Polycarbonate

Polycarbonate slate has a number of advantages over analogues. Sheets differ resistance to mechanical stress... Compared to plastic, the product shock resistant and is capable of carrying the weight of two people. This parameter is relevant in terms of roofing. Polycarbonate products UV resistant and does not fade after 10 years. In addition, slate is easily processed during installation and is attached to the frame. One person is enough to work.

Polycarbonate sheets have weighing 1.17 kg per 1 m² with a thickness of 0.9 mm.

Fiberglass

Production of fiberglass slate started in 2005... Used as raw material hardened glass fiber reinforced polyester resin... This gives the final structure strength and protects against precipitation.

A type of fiberglass is a polymer, which is made using a similar technology. However, the sheets have increased heat resistance and are resistant to temperatures from + 140 ° C to -40 ° C.

Fiberglass slate sheets are supplied to the market in rolls or in the form of a ready-made profile according to the type of profiled flooring.

Plexiglass

Corrugated sheets are a popular product from this raw material. It is noteworthy that one side of the slate has corrugated texture in the form of drops or ice... The main advantage of plexiglass is noise absorption.

Two technologies are involved in production - block extrusion and GS casting... As a result, the sheets are tear-resistant, not subject to deformation and do not crack during operation. Therefore, it is easy to create corrugated glass from it.

The plexiglass slate is recognized as environmentally friendly and safe for human health and life.

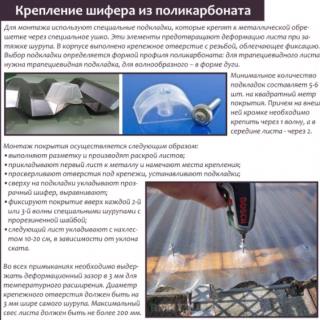

Installation rules

The processing of flexible transparent slate is not difficult - regardless of the type of raw material used, its easy to cut and mount... For work, you need to prepare simple equipment for metal and wood - angle grinder or construction knife... The light weight of the sheets assumes the use of appropriate self-tapping screws.

The average number of fasteners is 10 pieces per 1 m² of slate. Depending on the type of construction, the number of elements may vary.

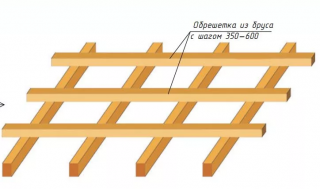

Features of laying wave transparent slate

To create the lathing, adhere to step up to 35 cm. Thermal insulation is installed if glass slate is used for arranging the roof.

Before attaching the screws, it is necessary drill holes for them in the material. The diameter should be on 3 mm larger than the screw section of the screw... These works should be carried out taking into account the expansion coefficient.

- Sheet material is stacked from bottom to top... Self-tapping screws are screwed in every three waves on the middle line, and every two - near the ridge, cornices and gutters.

- Use end profileb to give the structure a complete look. The element protects the under-roof space from moisture and debris.

- Install thermal washer to extend the service life of slate sheets at the time of thermal expansion. This element also prevents the fasteners from pushing into the base of the material, which could damage the surface.

- To join the individual slate panels, use special profiles... The building components can be selected in terms of thickness and material.

- Set sheets outwards with a protective layer against UV radiation... Otherwise, cellular polycarbonate will not last even 3 years. To determine the desired surface, pay attention to the manufacturer's logo applied to the protective layer. The film is removed after installing the panels on the crate.

Screw the self-tapping screw strictly into the crest of the wave. The location of the fasteners in the bend contributes to destruction under the influence of frost and moisture.

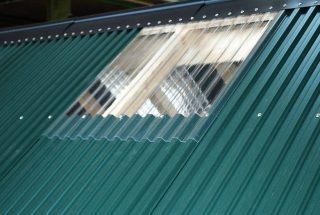

How to make a transparent roof insert

After that, lay down and fix the bottom row of transparent flat slate... It is allowed to install panels with an overlap with an approach to the previous sheet of at least 30 cm.

Fasten the insert from the sides to a wooden or metal frame. Press on top with a barpre-impregnated with a moisture-repellent preparation. This element will act as a fastener for the opaque material.

The joints must be treated with a sealant.... Upon completion, install the skate with fixing using self-tapping screws.