Slate has been used for a long time, its characteristics differ from those of modern roofing coverings, but the material is not afraid of fire, it is inexpensive. The size of the slate allows it to be used economically, since there is little waste during installation. Corrugated sheets are laid on slopes, the slope of which is not less than 12 °. Dimensions depend on the number of waves, the step between them on the surface of the material.

Slate information

Wavy and flat material is produced using a similar technology, using a raw material that includes Portland cement grade M300 - M500 for binding particles, chrysolite asbestos in the form of fibers, water. The roofing material is formed during the production process from composite components, sealed with water, then the mass hardens.

The mechanical properties of the resulting material depend on the volume of asbestos, which plays the role of a reinforcing frame in the composition of the sheets. In addition to strength, slate is characterized by low heat conductivity and water resistance.

Slate varieties are produced:

- natural look, it is also called natural, is obtained by chipping off plates of rock shale;

- asbestos-cement material in the form of corrugated or flat sheets;

- fiber cement - without the use of asbestos, instead, take mineral and cellulose fibers;

- polymer sand - similar to asbestos-cement, but instead of cement, sand and polymer binders are used;

- polycarbonate - translucent and transparent corrugated plastic sheets;

- composite - made of several layers, this type is called keramoplast.

The quality of corrugated slate depends on adherence to technology, adherence to the sequence of processes. In the past, wave sizes were not always maintained, so roofers had to sort the elements during the installation process. Now, at production, metal spacers are used to achieve high dimensional accuracy in the length and width of the slate.

The traditional coating is gray in color, but manufacturers add coloring pigments to the mass. The material is obtained in different colors.

Sizes of slate sheets

Flat roof slate is not used, as a rule, it is placed on partitions, walls, fences. The dimensions of the asbestos material are important for the correct counting of the number of pieces when installing the roofing. What matters is the height of the slate waves, their placement at a certain step.

Different types cannot be installed on the same roof. To repair the surface, take a material with a certain type of ridge so that its shape and size coincide with the previously laid elements.

Indicators of GOST

Asbestos-cement slate has been produced and used for a long time, therefore, standards have been developed that indicate dimensions, thickness, weight and other characteristics.

The material is produced in accordance with GOSTs:

- GOST 30.340 - 1995 “Asbestos-cement corrugated sheets;

- GOST 18.124 - 1995 "Asbestos-cement flat sheets".

Some manufacturers use their own developed technical specifications. Such products have non-standard sizes, differ in the dimensions of the ridge, length, thickness. This is allowed, but the products are difficult to work with. If you need to replace a sheet of such slate after a few years, you may not find a similar one.

GOST allows the production of two varieties:

- grade 40/150, with the step between the waves 150 mm, and the height of the ridge - 40 mm;

- brand 54/200, step - 200 mm, height - 54 mm.

GOST does not prohibit deviations from dimensions, but it is allowed to limit the discrepancy in length by 15 mm in one direction or another. The width of the sheet can be 10 mm more, and less - only 5 mm.

Wave slate

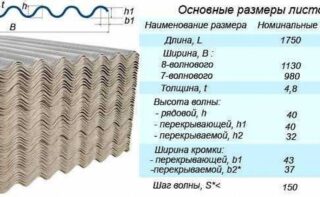

Product dimensions:

- parameters of 7-wave slate: length is 1750 mm; width - 980 mm;

- 8-wave pitta dimensions: length - 1750 mm, width - 1130 mm.

For the roof, not only roofing material is produced, but also elements that are added to it. They are made from the same raw materials, painted to match the color of the sheets.

In accordance with GOST, varieties are produced:

- simplified overlapping and simple strip (height 46 - 60 mm);

- simplified overlapping and simple lining.

Isosceles and trough angles are also produced. Shaped products are placed when decorating ridge ribs, valleys. They frame the joints of the roof with the wall, exits on the roof of protruding chimneys, skylights. There are details for organizing the rainwater drainage system.

Unified variant

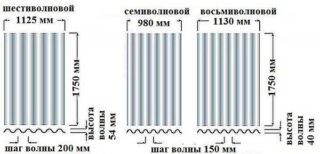

Dimensions of UV slate:

- 8-wave - length 1750 mm, width 1125 m;

- 7-wave - length 1750 mm, width 980 mm;

- 6-wave - length 1750 mm, width 1125 mm.

A unified profile is set if you need to cover the roof of a large square of a simple shape, without bends. Application leads to faster work, reduces the number of connections, and reduces the overall cost of construction. For installation, rafter elements with a cross section of 75 x 75 mm are used, the crate is placed in increments of 70 - 80 mm, depending on the slope.

Ordinary profile

Designated by letters VO. They are used to cover the roofs of private houses and structures with a small square. On small buildings, it is possible to avoid a large number of adjustments and cutting sheets to size. The set includes special elements made of asbestos cement for decorating the ridge, drain, wind boards. Profile thickness 5.2 mm for models 40/150 and 5.8 and 6.0 mm for models 54/200.

The dimensions are the same for sheets with a different number of waves:

- profile sheet width - 680 mm;

- the length is 1120 mm.

During installation, material is saved, since you can arrange a sparse wooden lathing from bars with a section of 50 x 50 mm. The elements of the lathing are placed at a distance of 50 - 60 cm, the step depends on the steepness of the slope. For rafters, bars of a cross-section of 75 x 75 mm are used, they are located at a distance of 0.7 - 1.0 m from each other.

Reinforced slate

Material with dimensions exceeding the two previous types is marked with the letters VU. Products have a maximum thickness of 8 mm for all varieties. Such material is used in large areas with a significant span of rafter legs.

Profile dimensions:

- width is 1000 mm;

- the length is made 2800 mm.

They place increased demands on the quality of reinforced slate. Products should have only right angles, not contain chips and cracks in the mass.

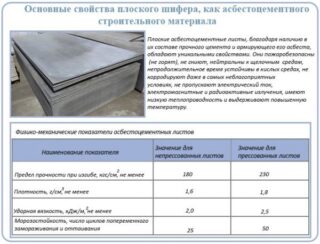

Flat material

They produce products of different sizes:

- 3000 x 1500 mm;

- 2000 x 1500 mm;

- 1750 x 1130 mm;

- 1500 x 1000 mm.

The most demanded panels are 1750 x 1120 mm. The thickness of such sheets varies in the range of 8 - 20 mm, this changes the weight of the board.For example, with a thickness of 10 mm, the product weighs 40.1 kg, with 8 mm - 30.5 kg, a thickness of 6 mm gives a weight of 21.2 kg.

Number of waves

The optimal number is considered to be seven and eight waves on one slate plate. This type is most often acquired to cover a small residential building, dacha. For eight- and seven-wave plates, the useful square is not too different from the total area. This happens because the wave slate is laid with an overlap in one wave, and this is not much compared to the overall dimensions. For the convenience of overlap, the protrusions located on the edge differ in size, GOST allows such a deviation.

Common sizes for eight-wave slate and seven-wave slate:

- wave height (crest) —40 mm;

- step - 150 mm;

- wall thickness - 5.2 or 5.8 mm.

Panels with six and five waves are more often used in manufacturing. Industrial workshops, warehouses, hangars are covered with long strips, and it is unprofitable to install them in private houses. The size of the sheet with 8 ridges is the same as for the panel with 5 and 6 waves, but during installation it is necessary to overlap one lip. Therefore, the useful area of the 5th and 6th wave profile is significantly reduced.

Sizes of six- and five-wave sheets:

- the length is 1.75 m;

- in width - 1.125 m;

- the step between the ridges is 200 mm.

The thickness of the five- and six-wave material is on the order of 7.5 mm, so that it breaks less when bending, loading and impacting. Sheets of this thickness can withstand negative temperatures two times lower than thin-walled slate.

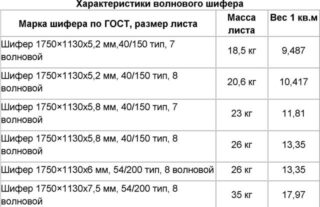

Slate sheet weight

Approximate weight of elements:

- a sheet of seven wave slate 1750 x 1130 x 5.2 mm, 40/150 weighs 18.5 kg, and a square - 9.48 kg;

- seven wave 1750 x 1130 x 5.8 mm, 40/150, respectively, 23 and 11.81 kg;

- eight wave 1750 x 1130 x 5.2 mm 40/150 weighs 20.6 and 10.42 kg;

- eight wave 1750 x 1130 x 5.8 mm, 41/150 - 26 and 13.35 kg;

- eight wave 1750 x 1130 x 6.0 mm, 54/200 - 28 and 14.85 kg;

- eight wave 1750 x 1130 x 7.5 mm, 54/200 - 35 and 17.97 kg;

- a flat sheet with a thickness of 6 mm, dimensions 3.6 x 1.5 m, pressed weighs 70 kg, unpressed 64 kg;

- flat 3.6 x 1.2 m pressed - 56 kg, unpressed - 51 kg;

- flat 3.0 x 1.2m - 47 and 43 kg;

- flat 2.0 x 1.5 m - 48 and 44 kg.

More powerful rafters are calculated under the slate, since the weight of the snow and wind pressure are added to the mass of the coating. Modern material is coated with protective compounds to increase resistance to negative factors, to extend the service life.

Effective coverage area

For conventional slate elements, the usable area matters:

- size of slate 8 wave - 1.57 m²;

- 7-wave slabs - 1.336 m².

The indicators are valid for one wave overlap, which is more often used when installing a slate roof. In other words, the useful square is the total area reduced by the overlapping area.

You can calculate the real volume of material by dividing the area of the slopes by the value of the useful square of the sheet. The roof area is considered by multiplying the length of the ramp by its width. If the roof is gable, consider squaring for two slopes.

To calculate the useful area of the sheet, use the formula Sп = S kwhere:

- S - slate area;

- k - the coefficient of useful quadrature, how much the slate sheet overlaps, for a single-wave overlap, k = 0.8 is used, two waves will require a coefficient of 0.7.

The roof area is divided by the usable area of one panel, the number of elements is obtained. The result obtained is multiplied by 1.1 to account for cutting and fighting during transportation.

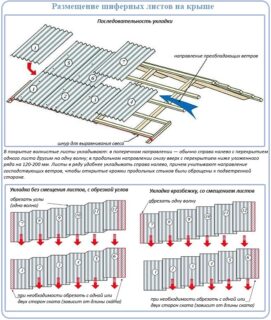

You can count in another way.Measure the width of the roof in the area of the eaves, the resulting size is divided by the width of the sheet without one wave. Get the number of items in width. The length of the slope is divided by the length of the slate, taking into account the overlap in length - the number of rows is obtained.

Quality control and dimensions of finished products

The manufacturer coordinates technological processes, the quality of raw materials, pays attention to the compliance of the finished slate with standard tolerances and dimensions.

Control procedure:

- each of the imported consignments of raw materials is issued by the supplier with a special passport, and the laboratory conducts visual and chemical control;

- workers take samples, test them, check properties;

- the laboratory transmits the results to the technical control service, where they issue a permit for the use of raw materials;

- the company coordinates technical processes, checking the sequence of operations, raw material consumption and compliance with the concentration of the constituent components of the solution;

- the labor control department checks the pressure, temperature during production, controls the appearance of slate products, section, dimensions.

The finished products are coordinated by the factory laboratory station, the workers carry out chemical tests and exercise. Samples are taken from the produced batch, they are checked, then a conclusion is made on the quality and compliance with the dimensions. The list of checks is also regulated by GOST.

The results of testing of asbestos-cement panels are included in the technical passport, which is issued for a batch of goods. The document also includes the name of the enterprise, address, brand of the product, its grade, external signs, weight, the number of elements in the batch, and the date of issue.