Rolled roofing material is produced by impregnating a cardboard sheet with petroleum bitumen with a low melting point. Then it is covered with refractory bitumen on both sides and a layer of dressing is applied to prevent sticking and to increase its protective properties. The manufacturing technology is regulated by GOST 10.923 - 1993, the document contains requirements for the dimensions in width, the length of the roll, the thickness of the roofing material is regulated in 1 layer.

Types of roofing material

Manufacturers give additional qualities to the produced material with the help of mineral chips on the surface, additives. The sprinkles are made from different materials, for example, talcum powder, natural stone chips, and foam. The layer can be of different colors, but it must adhere firmly to the plane of the sheet in order to qualitatively protect the material from ultraviolet radiation for 10-15 years.

They produce varieties of roofing material:

- Armored. It is characterized by a high strip density of up to 500 g / m². The dressing must be colored, because the paint coating better captures ultraviolet rays and extends the service life.

- Euroruberoid. Refers to modified types, instead of cardboard, fiberglass or fiberglass is used in the composition. The top cover is made of refractory bitumen with the inclusion of polymer materials. The impregnation is carried out from two sides of the sheet. The service life is about 25 years. Euroruberoid is subdivided into liquid and weldable.

- Uniflex. The bitumen-polymer coating is included in the structure of the roofing carpet, where it is used as a waterproofing layer. An artificial elastomer (rubber) is introduced into the composition, the additive gives the material resistance to freezing and low heat conductivity. The lower, upper and integumentary uniflex are produced.

- Reinforced. Reinforced base adds extra punching and flexural strength. Fiberglass is connected to a plastic mesh, a polymer-bitumen mixture is applied on top. Use granite or slate chips for sprinkling. Reinforced roofing material in one layer replaces 3 layers of simple material.

- Self-adhesive. Freely fixed by means of an adhesive layer on the underside to wood, concrete, iron. Any glued sheet serves no more than ten years, even if the laying technology is observed. It is also installed as part of waterproofing under metal tiles, profiled metal, ondulin, slate.

Liquid euroruberoid is not referred to as sheet materials, since it is melted and applied to a flat solid base of the roof. A mass of rubber is used for spot repair of a roofing felt carpet when dismantling a damaged area.

The euroruberoid to be welded is mounted after heating the lower layer with a gas burner until it melts. The basis is polyester fiber or fiberglass. A mineral dressing is made on top of the fabric to be welded. Installation time is reduced as no mastic is required on the base of the roof. The material is used for the top layer and as insulation from moisture.

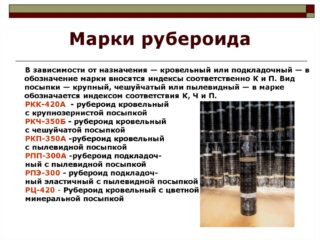

Decoding of roofing material brands and examples of marking

Letters are used according to the international standard:

- the first letter P - speaks about the category of material (roofing material);

- the second - means the type of roofing material, use K (roofing) and P (lining);

- the third indicates the type of outer crumb, for example, M - small groats, K - coarse grains, H - scaly layer, P - in the form of dust, talc, E - increased elasticity, C - persistent dyes were used.

A dash is followed by a figure that indicates the mass of 1 m² of the base, laid down during manufacture. The density and strength of the material, the weight of the roofing material roll depends on the indicator.

The most used brands of roofing material:

- RCP - 350. The density of the cardboard in the base of the roofing material is 350 g / m². There is a dusty bedding on the surface. It is produced in rolls with a length of 15 meters in a standard width. They are used for the lower part of the roof, or they are used as a top covering.

- RKK - 350. The brand is represented by roofing material with topping in the form of large mineral grains, and the density of the cardboard in the roofing material is 350 g / m². The moisture-proof fabric does not collapse when the air temperature rises to + 80 ° C. Rolls of 10 m are used to cover the roof.

- RKK - 400. Thick material with coarse-grained chips on the surface, the square of the base weighs 400 g. Rolls are produced 10 m long, a moisture-resistant sheet is glued as a covering layer on a flat and pitched roof.

- RPP - 300. The basic density of the base has an indicator of 300 g / m², the strips are used in the form of a lining intermediate layer in the composition of the roofing carpet. There is a dusty layer on the surface, which prevents the roofing material from sticking together during transportation and storage. The roll has a length of 15 meters, the width of the roofing material is standard.

- RPP - 200. Lining ruberoid cloth with dust-like powder. The basis is fragile, density - 200 g / m². They are used for waterproofing under other roofing coatings, but as an independent coating they are not used due to their short service life.

Roofing material is installed as waterproofing not only on roofs, it is used as a hydro-barrier for concrete structures of walls, basements, and foundations. In any case, the sheets show good insulating properties. The disadvantages include flammability of sheets and low strength.

Regulated sizes

The values of density, weight, mass and other dimensions are indicated in specially developed GOSTs. The quality of low-melting and high-melting bitumen is regulated by GOST 66.17 - 1976 as amended. The required characteristics of the cardboard are prescribed in the document GOST 22.245 - 1990, and the fiberglass is standardized in accordance with the instructions of NPG - 210, T - 13. There is also GOST 21.235 - 1977 for coarse-grained bedding, sand (GOST 87.36 - 1993).

The main dimensional indicators of ruberoid products:

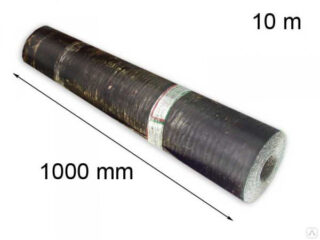

- Width. According to the regulations, the width of the roofing material roll should be 1000 mm. If manufacturers develop their own specifications, in accordance with them, it is allowed to reduce and increase the size by 50 mm. Rolls are also produced with a width of 750 mm, such are taken for roofs of a small square.

- Length. GOST regulates that there should be 10 meters in a roll of roofing material. Manufacturers who work in accordance with GOST adhere to this requirement. Manufacturers using TU make rolls of 15 and 20 meters. At 20 m, a material for lining purposes is produced, which has less weight and thickness. Many manufacturers make the length at the request of the buyer.

- Area. If the roll is 10 m long, according to the standard, its square should be at the level of 10 m², while tolerances allow a deviation of 0.5 m² in one direction or the other. For a length of 15 m, the area will be 15 m², for 20 m - 20 m² with the same tolerances. The area is important for calculating the required amount of canvas on the roof.

- Density. The value indicates the weight of one square of a base made of building board, polyamide canvas or fiberglass. Specifications and GOST provide for a density of 200 - 500 g / m². Cloths with lower values are put on insulation, and higher density is used for the top coating.

- Thickness.The manufacturer's specifications allow for an indicator at the level of 2.5 - 5.0 mm. The last layer on the surface is made with a thickness of 4 - 5 mm, and the lower ones can be set thinner. Usually, several layers of material on bitumen mastic are used for covering, therefore, the total carpet is obtained at a level of 1.6 - 3.5 cm.

- Roll weight. The variable indicator depends on many characteristics, such as the size of the roofing material along the length, the thickness and density of the inner layer, the type of external and internal dressing. The weight of a standard unit is 25 - 30 kg. At the same time, roofing varieties have a greater mass than lining products.

In the documents for the goods, the brand of the material must be indicated, and all the characteristic indicators of quality and properties are also put.

The choice of roofing material for quality

When buying, you need to check the product for certain tags, which indicate the good condition of the product. The number of tears at the edges of the roll is not more than two, and the length of the gap should not exceed 3 cm.

Other verification rules:

- tightly wound tightly, the roll is the same on both edges, without protrusions of the inner layer (protrusion at the ends is not more than 15 mm is allowed);

- the specified type of coating is on both sides, and the inner base on the cut is impregnated with resin without light areas;

- the products are packed in paper at least 0.5 m wide, stamped and marked on it;

- the edge of the material of the same thickness along the entire length.

The dimensions of the canvas must comply with the standards or have small deviations, which are also regulated. The dressing should not be erased from the area of the material by hand, no cracks are allowed on the surface.