Types of metal tiles of various sizes, shapes and colors are widely used in private and commercial construction. Products combine presentability, strength, durability, affordable cost and ease of installation, which can be done by hand. In order not to be mistaken when buying a material, you need to figure out the options for its format, composition, coloring and methods of applied protection from external factors.

Material description

The concept of metal tiles is understood as metal sheets intended for laying on the crate of a rafter system of a pitched structure. The products imitate a ceramic coating through the use of embossing and the application of a pattern characteristic of natural tiles. Cladding is used on slopes, the steepness of which exceeds 20 degrees. Laying is carried out in separate sheets with screwing along the level of the upper edges.

The use of various options for metal tiles allows architects and builders to carry out original and beautiful finishing of the roofs of cottages, public buildings, commercial buildings, industrial buildings, objects of historical and cultural value.

Varieties of metal tiles by material

In construction, varieties of metal tiles are used, which are made with the following basis:

- Steel. The most common cladding composition. The base is a galvanized iron sheet. The product is inexpensive, but quite heavy and corrosive.

- Aluminum. Non-ferrous metal does not rust, and therefore only UV protection and wear-resistant paint are used. The panels are lightweight, unpretentious to the weather, but they also cost a lot.

- Copper. As a rule, such tiles are not subjected to additional processing. Copper looks great at all stages of aging. However, such a luxury comes at a high price.

When deciding on the composition of the material, it is necessary to evaluate not only its price, but also compatibility with the style of the object.

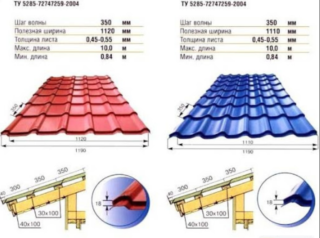

Types of metal tiles depending on the size and thickness of the metal

Panels with a length of 50 cm to 6 m are on sale. The former are used to cover narrow strips in the area of the ridge, the latter are used when arranging large objects.

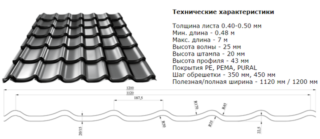

The thickness of the corrugated board in millimeters indicates where and in what conditions it can be used:

- 0.35 - for decorative purposes only;

- 0.40 - in places where there is no snow and wind load;

- 0.45 - for roofs with a slope of more than 30 degrees, but even there there is a risk of deformation during installation;

- 0.50-0.55 - the most common format, characterized by sufficient strength and versatility;

- 0.60-0.70 - strong types that are made to order, which determines their high cost.

The description of the product is given in the instructions, but this data must be checked. It is not uncommon for the deviation to the smaller side to reach 0.07 mm. And these are completely different performance characteristics.

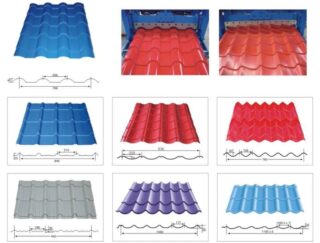

Types of metal tile profiles

Modern metal tiles have a wide variety of profile types, which allows developers to choose the desired coating option for a building of any style and size.

The most common types of waves are:

- Andalusia.Has a lock covering that ensures tightness. The slopes look smooth and neat.

- Banga. Differs in refinement of shape and increased height of the ridge.

- Joker. The classic shape of the same waves. Appreciated by adherents of the classics.

- Cascade. The sheets resemble a large chocolate bar with smooth rectangular shapes.

- Credo. Interesting figures that attract attention with their non-standard and originality.

- Cron. Such a covering resembles a log flooring, appreciated by adherents of the country style.

- Monterrey. Smooth profile curves look great and are suitable for all styles of buildings.

- Shanghai. The symmetry of the grooves and grooves combined with the height of the wave makes this model easily recognizable.

- Sicily. Italian classics with natural ceramics will appeal to fans of this trend.

There are many more models, their range is replenished every year, as manufacturers are constantly improving the design and technology of their products.

Front surface coating

The type of protective layer largely determines how many years a metal tile roof will last, and also affects its appearance and presentability.

- Polyester. Inexpensive, short-lived and poorly tolerant of negative temperatures. Sometimes matte and shiny.

- Pural. Durable, UV-resistant, but quite expensive.

- Purex. Beautiful, flexible, resistant to external factors and extremely durable.

- Plastisol. The PVC backing is strong and moisture resistant. It collapses in the cold.

- Polyurethane. Practical and durable. Softens in extreme heat.

- Solano. It has an original dot-embossed texture. It protects well against corrosion and mechanical stress.

- Prisma. The composition of polyurethane foam, aluminum and zinc looks beautiful, resistant to external factors.

- Kami TerraPLEGEL. Multi-layer coating consisting of polymer, quartz sand and a polyester outer layer. The most durable material available today.

- PVDF protection. Excellent protection from sun, hail and rain. Long service life.

Domestic products today are practically not inferior in quality to foreign counterparts.

How to choose metal roof tiles

It is rather difficult to choose the optimal coating option, since the modern market is saturated with roofing materials of various designs, shapes and sizes. You need to find a middle ground between price, quality and presentable appearance.

When making a decision, you should carefully study the following criteria:

- anti-corrosion properties, applied primer and protection technologies;

- thickness to ensure safe transportation and stacking of panels;

- resistance of slabs to wind and snow load;

- aesthetic characteristics corresponding to the landscape design of the site;

- the ability to carry out installation, maintenance and repair with your own hands.

The price side also matters, but only within reasonable limits. With cheap material, problems can arise even at the stage of laying on the base. In the future, such disadvantages as loss of color, corrosion, violation of the coating from the sun, heat or frost will certainly appear.

Practical advice

When buying metal shingles, it is recommended to follow these rules:

- Do not use panels thinner than 0.45 mm. Such sheets easily wrinkle when pressed by hand, falling fruits and branches from trees.

- Purchase goods only in reputable retail outlets, with a quality certificate and a guarantee.

- Look at the country of origin of the product. Tiles from Europe are considered the best today, followed by Russia, it is worthwhile to be wary of the material from the countries of Asia and the CIS.

- All sheets should be even, uniform in color, without dents or scratches. The ends of the panels from a good manufacturer are also treated with a primer and a protective coating.

- Features of packaging. In a conscientious manufacturer, it is durable and thoughtful.The product will easily transfer any transportation and will reach the consumer intact.

- Wave height. The larger it is, the stiffer the slabs, the less risk of damaging them during transportation and laying.

It is worth paying attention to the texture of the plates. For steep slopes, it does not really matter. If the roof is sloping, you should take tiles with a minimum height of the transverse relief so that snow and debris do not accumulate on it.