The decision to use siding for interior wall decoration cannot be called traditional, since this material is usually considered as an external cladding. However, this idea has a well-founded right to life. The operational and technical characteristics of the panels are consistent with the conditions of use inside the house.

Description of finishing material

Siding is presented in a wide range of sizes, colors and textures. Products are monochromatic, imitating natural and artificial materials, made from various raw materials.

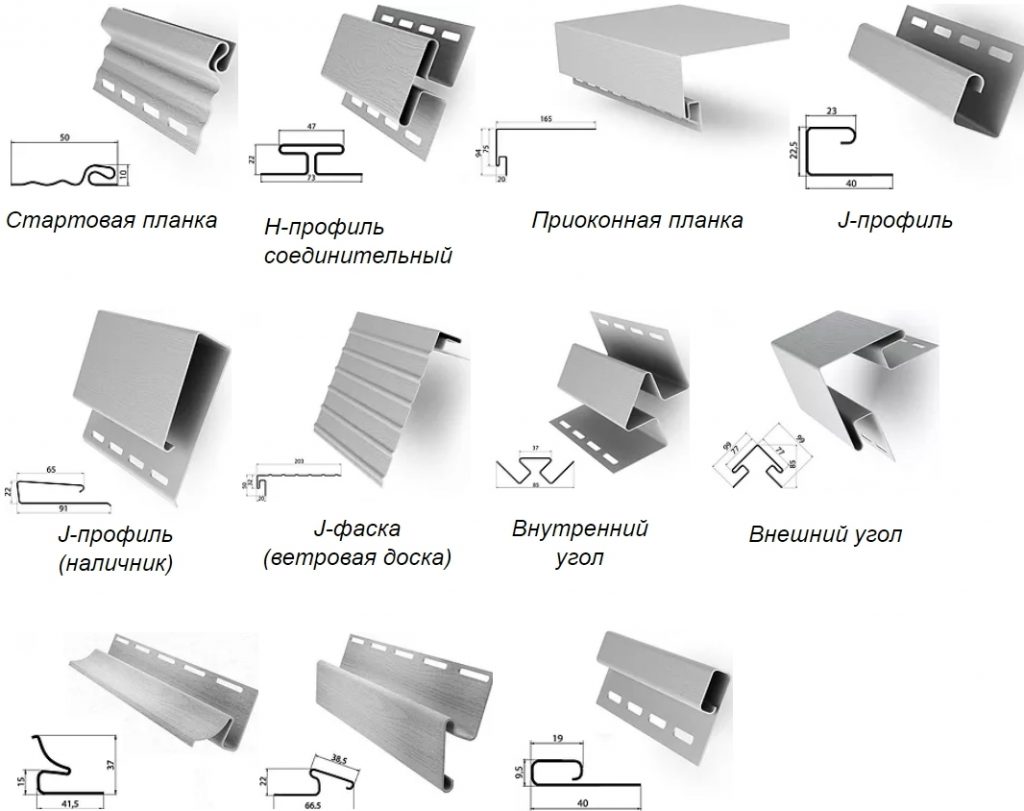

Size standard is 200-600 cm in length and 15-50 cm in width front strip. There are numerous additional details (corner, docking and end profile), allowing you to beautifully and practically decorate rooms of any purpose. Indoor siding is a great and budget alternative to expensive wall paneling, liquid wallpaper, or short-lived plastic panels.

Types of siding for interior work

A large number of panels can be found on sale, the scope of which is largely determined by the composition.

In construction, the most popular are types of lamellas:

- Plastic. PVC, acrylic and vinyl are used as raw materials. Products are characterized by low thermal conductivity, resistance to dampness, which allows their installation in damp rooms. They do not tolerate high and low temperatures.

- Wooden. Natural raw materials are popular due to the naturalness and warmth of the lath surface. They are made of solid wood or veneer glued to the base of chipboard or fiberboard. Finished products imitate a bar, log or board. They can be used in dry rooms such as a corridor, bedroom, hallway.

- Metallic. The strips are made by pressing from steel with a thickness of 0.4-0.6 mm, followed by applying a decorative and protective coating. The coating is durable, resistant to temperature extremes and aggressive environments. It is rarely used in living rooms, more often for utility rooms and industrial buildings - sheds, garages, workshops.

The interior uses wood-imitating finishes, silicate and ceramic bricks, limestone, granite, cobblestones and facade plaster. 3D panels are very popular. The choice is made based on the design of the object, its own taste priorities.

Application for interior decoration

If it is not difficult to decide on the color and texture, then the choice of material for finishing a particular room should be approached more responsibly, carefully and thoughtfully.

There are such criteria:

- Bathroom... The object is characterized by high humidity and a high probability of splashing and water jets on the walls. It is better to use plastic coatings here, and without internal voids. Polymer battens have low thermal conductivity and are pleasant to the touch.You can fix them on a steel frame, but it is more advisable to put them on glue. There are no special requirements regarding color and texture.

- Kitchen. There is humidity and significant changes in temperature here, but all this is of an uncritical scale. Therefore, it is possible to apply the panels zonally - metal at the desktop, plastic opposite the stove and sink, and install a wooden flooring in other places.

- Balcony and loggia. These are extreme places in all respects. They are exposed to heat and cold, moisture, wind and ultraviolet radiation. Don't forget about birds and insects. The best solution is vinyl that can withstand these factors. Steel slats can be put on top. If the object is glazed and heated, there are no restrictions on finishing.

When deciding on the material of the frame, you need to take into account that even galvanized iron begins to rust over time, and the wood deforms and rots.

How to choose a siding

After determining the material, color and embossing option, you need to carry out calculations and make an estimate. Should provide stock up to 20% for clipping and errors.

When buying, you need pay attention to such moments:

- Manufacturer. It is better to take products of well-known and proven brands, check for certificates.

- Completeness. Along with the panels, fasteners and additional parts are purchased. It is desirable that they are of the same brand. This ensures that they will match in color and size.

- Product quality. This means the absence of chips, cracks, scratches, distortions. The packaging must be marked with the brand, model and date of manufacture.

If the construction is temporary, it is better to stay with the budget option. When it is calculated for many years, you should not be guided by the price.

Installation features

Installation of lamellas is simple enough that even a novice master can cope with it. Some features of fastening technology.

Installation of panels on walls can be carried out with vertical and horizontal orientation. The first option is good for dry rooms, the second is advisable to use where moisture is present. This will avoid the accumulation of water in the crevices. In all cases the frame is made perpendicular to the panels.

Construction procedure:

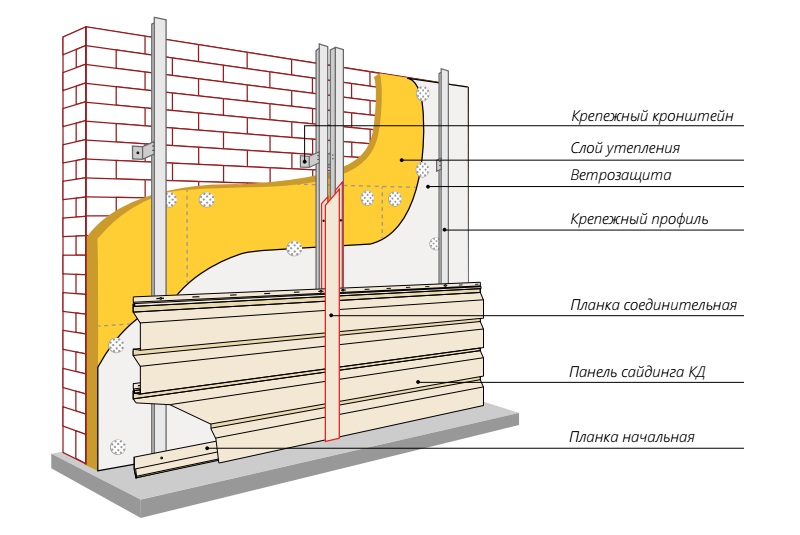

- Cleaning the base from unstable fragments, sealing depressions and holes, treating it with an antiseptic.

- Marking, making holes for lathing.

- Assembling the frame. The tree is pre-dried and treated with a hydrophobic preparation. The edges of the metal are painted over.

- Insulation laying. At the same time, it also performs the function of sound insulation.

- Fastening starting bar and corner pieces. Carrying out stacking panels.

- Closure of the flooring finishing profile.