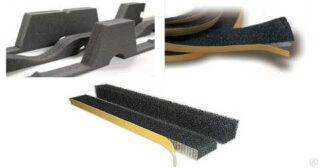

The roofing seal is laid between the metal profile and the roof ridge. Profiled sheets are characterized by a corrugated surface, and the ridge edge is usually flat. A sealer for corrugated board is used to eliminate the gap between structural elements and to make sure that the surfaces coincide despite the different shape.

The need to use a special seal

The ridge is a connecting line of two roof slopes located at an angle. Proper arrangement of this area is essential for the smooth operation of the building. The ridge cover is a longitudinal corner piece that is placed on the intersection line.

The gasket, corrugated on one side, protects the under-roof gap and the attic space from moisture, therefore, increases the service life of the roofing flooring.

Other functions of the sealing strip:

- provides ventilation with simultaneous equalization of ventilation flows, reduces the risk of condensation droplets by reducing the blowing capacity;

- protects the area under the ridge from clogging, protects against clogging of foliage, snow;

- increases the degree of isolation from noise.

On sale there are insulators for all forms, made of different materials. All tapes are reasonably priced and installation is simple and convenient.

It is not worth neglecting the seal in order to subsequently avoid troubles during operation. Foam rubber, polyethylene lining serves as an additional heat insulator for the attic.

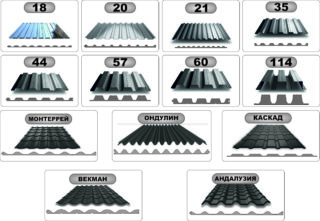

Application features

The gasket is given a special shape that follows the shape of the waves of a metal tile or a profile sheet. For all types of roofing, their own type of seal is made. The material is selected according to the type of corrugation in order to isolate the gap as efficiently as possible, to achieve complete tightness. For example, the compactor for C8 corrugated board differs in size from the gasket for H57 corrugated sheet, since the materials have different wave heights.

Varieties are used according to the type of location of the relief layer:

- if it is on top of the seal, the gaskets are intended for the gap between the eaves overhang and the metal profile;

- the lower arrangement of the figured surface is suitable as a seal under the ridge of a metal tile.

The scope of use of each individual model of the seal is limited, since it corresponds to a special type of profiled flooring or metal tile. Difficulties also arise with the order of additional elements for the roof, which cover the valleys, gutters, docking with windows, ventilation outlet, chimney.

Varieties of gaskets and their characteristics

The seal for the ridge of the metal tile is made of polyurethane foam under pressure. The cellular material is flexible, fills gaps well, retains its shape. The synthesis of a substance and obtaining a given shape occurs simultaneously when mixing under pressure and injecting into a special matrix. Polyurethane foam contains 85 - 90% gas in the structure, it can be of greater or lesser density.

The following types of ridge seal for metal tiles are used:

- universal;

- profiled;

- self-expanding.

Lining of different models from 20 to 30 years old. It goes on sale in the form of strips with a length of 0.6 - 1.15 meters for profiled steel and 2.0 meters as a universal material for other types. All models can be easily cut and glued. Working with them is safe for health, since foamed polyethylene belongs to the group of environmentally friendly materials.

Universal

Produced in the form of volumetric strips, on which an adhesive is applied on one side. The cross section comes in different sizes as well as shapes. The gasket, soft in structure, quickly takes the required shape, fills all free voids.

Features of the universal sealant for metal tiles:

- inexpensive material;

- effectively protects the under-roof gap;

- the porous structure expands and contracts easily;

- simply glued to concrete, wood, steel.

Universal strips are not particularly suitable for the configuration of the metal profile, since the material easily fills in the gaps. It is placed not only under the ridge and eaves, the tapes are well suited for insulating other roofing joints.

The strips are packaged in 100 pieces in one package. When opened, they are stored in a dry place, protected from sunlight.

Profiled

Foamed polyethylene of increased density is used, modified in the production process with special additives. This type of sealing tape is selected for each profile configuration. During manufacture, one side of the seal for the profiled sheet is cut out in the shape of the waves to ensure a perfect fit. Holes are made in the body of the gasket so as not to disturb the air circulation.

Features of the profiled seal model:

- has about 40 configuration options for different coatings;

- hard, embossed, dense material;

- for fixing, adhesives, sealants, and nails are used.

The installation method depends on the type of gasket. It is not recommended to stick the tape at temperatures below -5 ° С, and on the surface for applying the composition should not be less than 0 ° С. There is an option for attaching the seal to self-tapping screws or nails with wide caps, while the temperature outside does not matter.

Self-expanding

Popular view due to the versatility of installation, efficiency and ease of use. Initially, when released, the foam is compressed under pressure, in this state it remains until the period of use. After removing the protection, such material expands, while filling even small gaps. There is also an adhesive strip on its surface for mounting.

The self-expanding profiled sheet compactor has the following features:

- suitable for installation in different cases of roof joints without restrictions;

- effectively insulates surfaces that are dissimilar in shape and material;

- sold in the form of compressed rollers with a self-adhesive strip covered with a protective layer;

- the foamed base is impregnated with acrylic polymer.

The released band automatically begins to expand itself, protecting the gap from the influence of negative factors. The greatest degree of build-up is achieved after 5 - 8 hours. The expansion rate depends on the surface and air temperature.

Features of the choice of tape

Foam rubber under the ridge of the profiled sheet must meet certain requirements for the protection to be effective.

Buying Tips:

- Choose the model that the manufacturer recommends for the type of corrugated board or metal tile used.

- They purchase tapes with high properties of resistance to water absorption, since budget pads are often made in violation of technology. When wet, the tape deforms, shrinks, exposes cracks.A wet seal does not allow air to pass through, but it conducts heat and sounds.

- The ridge insulator serves as a barrier to debris, but not to air flows, so pay attention to the tightness of the gasket. Rigid materials impede roof ventilation.

The resistance against freezing and thawing is important, since the material must remain elastic for a long time. Consider resistance to fire, the ability to withstand chemically active air components.

Installation instructions

Rules for arranging the junction area:

- For a complex bifurcating Y-shaped ridge, special special linings are used, self-tapping screws are required here, regardless of the adhesive film on the gasket.

- The seals are also placed parallel to the eaves, on inclined convex ridges, in the depressions of the roofing planes.

- All fastening hardware and the seal itself must be covered with a ridge element so that they cannot be seen from the outside.

The self-adhesive look is more convenient and faster to apply. If self-tapping screws are used, choose a galvanized coating.

Tips & Tricks

Manufacturers claim that self-adhesive strips adhere well even to rough and dusty surfaces. But builders recommend cleaning the profile from dust, dirt, grease and other substances on the surface.

During installation, the tape must not be stretched, it is unnatural to bend it. If it is necessary to connect the gasket, they do it end-to-end with additional fastening with self-tapping screws.

When working in frosty weather, the sealing strip is kept warm for some time. The surface can be blown with warm air from a hair dryer, and after installation, the tape itself is heated with a warm stream at a distance of no closer than 15 cm.