The glazing of a private house and courtyard buildings with monolithic polycarbonate is becoming more and more popular. Transparent plastic is highly durable, lightweight and can be installed with your own hands. To achieve a high-quality result, it is necessary to figure out how the cutting of monolithic polycarbonate should be carried out, in the features and rules for performing this process.

The need for proper cutting of polycarbonate

Polycarbonate is a solid material produced from carbonic acid and two atomic alcohols... The polymer is characterized by hardness, toughness and low melting point. The plates crack from mechanical stress, but do not break. Excessive ambient temperature leads to the occurrence of fluidity and deformation of the polymer.

Cut monolithic polycarbonate you need with minimal vibration, pressure and no overheating.

The slabs are light, but with a large area and thickness, you will have to make an effort to transport them. Another factor to consider is the softness of the surface. It is very easy to scratch, a smooth and soft bedding is required.

Cutting tools

To fit the polycarbonate sheet to the desired format, you can use one of the household tools that are available in any household.

Cutting polycarbonate in size can be carried out such devices:

- Bulgarian (angle grinder)... The product is simple, but requires a firm hand and experience. In addition, only models with speed control are suitable. At 11,000 rpm, the plastic simply melts at the edges.

- Stationery knife. Requires quality devices without backlash and with a sturdy handle. The maximum thickness of the slabs is 6 mm, subject to skill.

- Jigsaw. You can cut plastic not only in a straight line, but also along a curved line. A fine-toothed nozzle is required to install.

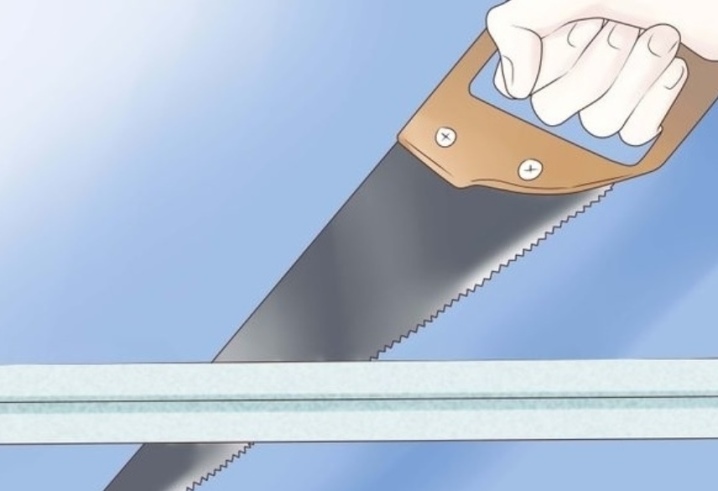

- Hacksaw for metal. The hand tool allows precise cuts to be made without the risk of making mistakes. The downside is that it will take a lot of time and effort.

- Fraser... The tool allows you to cut slabs quickly and accurately, but subject to the installation of a blade with fine notches.

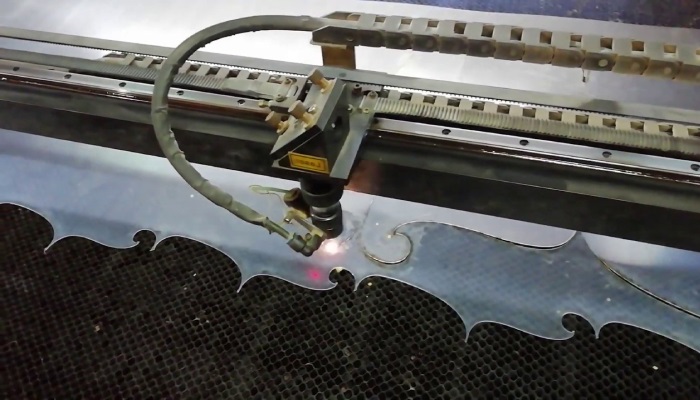

- Laser machine... Ideal for cutting plastic boards. Differs in maximum speed, accuracy and zero waste.

If you have several tools in your arsenal, you need to try to work with them on scraps of material and choose the one with the help of which the best results are achieved.

Material cutting technology

Step-by-step instructions for use are included with every power tool and some handheld tools. The efficiency and safety of work depends on the implementation of the manufacturer's recommendations.

Polycarbonate cutting technology assumes compliance following rules:

- Bulgarian. You need to take the most small disc 125 mm... The best are diamond-coated blades. They pass the web quickly, practically without heating. The separation of the web is not due to friction. Before opening the sheet, you need to fix it well, and hold the tool when working with both hands. You need to lead the canvas as quickly as possible, trying not to linger in one place for a long time.

- Stationery knife. A steel ruler or long metal strip is required to cut the blade evenly.First, a line is laid, then a ruler is applied to it, and a blade is drawn along its edge. You need to lead it slowly, pressing firmly against the sheet and the stop. It is imperative to use protective goggles and gloves. After applying the groove, the sheet is turned over and the process is repeated. The workpiece is then pushed to the edge of the table and cracked with both hands.

- Jigsaw. The device is designed in such a way that the saw teeth are directed upwards; when moving, it creates a perceptible vibration and makes large chips. Therefore, you need to put plywood on top and bottom or cut off several pieces at once from the plates stacked in a pile. So vibration is reduced to a minimum, the edges are smooth. If in the process of cutting the saw goes to the side, the excess is removed with a knife or grinder.

- Hacksaw. The blade should be thin, strong and finely toothed. Use the blade and cut at a very sharp angle to cut and not tear the material. The accuracy with this method will be much higher. The edges of the workpiece must be well pressed. When the blade approaches the end of the sheet, you need to stop and make a counter cut in order to avoid splitting off the plastic.

- Fraser... This is a powerful and heavy tool. When working, the cutting line should be as close to the edge of the table as possible. It is desirable that the other side is also supported. The circle must be set sharp, set the average speed.

- Laser. Laser cutting of polycarbonate produces top quality results with smooth edges. It is not necessary to fasten the sheet on the base, since there is no mechanical effect on it. It is advisable to buy such a device if there is a large-scale polycarbonate glazing of several buildings on the site of a summer cottage or a private house.

All methods are not particularly difficult. The main thing is to perform all actions calmly, without haste, taking into account the peculiarities of the operation of a particular tool.

Key recommendations

Regardless of the chosen technology for cutting monolithic polycarbonate, a number of simple but effective rules:

- Availability is enough wide, level and stable table... If it is too small, you can screw a large slab on top and cover it with a blanket.

- Make sure that on the work surface there was no debris and foreign objects... They can scratch the plastic sheets.

- If you have to make many blanks with straight and curved shapes, you will need to prepare a whole set of tools. A grinder or a hacksaw for straight lines, a jigsaw for circles, a knife for an accurate fit.

- Protective film with sheets are removed only after the end of processing immediately before installation.

- Markup is applied to the panels with a black marker. It cannot be wiped off by hand, but can be easily removed with alcohol.

- Cutting lines it is better to transfer from a sheet of paper with an applied outline placed under the plate. Longer lines are best drawn using a board to avoid scratching the material with metal.