Roofing material is a popular roll material used to insulate various building structures. The material is very easy to use, weighs little, and has an affordable cost. Several brands of roofing material are produced for different purposes.

What is a modern roofing material

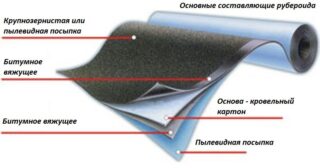

- The basis of roofing material is roofing board impregnated with bitumen, with a density of 200-420 g / m². It provides sufficient density and rigidity. Later, fiberglass and polyester were also used as a base. This option provides resistance to mold and decay and provides high water resistance. The base is immersed in the bathtub for 10–20 seconds to soak in low-melting bitumen.

- Refractory bitumen - with the addition of polyester resins and synthetic rubbers. This layer prevents moisture penetration, increases resistance to low and high temperatures. The top layer of bitumen prevents cracking and imparts a certain flexibility and ductility to the roofing material.

- The bottom layer of the same bitumen is intended for adhesion to the surface. When laying, this layer is heated with a burner so that it melts, and then the canvas is pressed to the surface. Bitumen hardens, forming a single whole with roofing felt and the base of the roof.

- Spreading is a mixture of stone and mineral chips. The particles can be of different sizes, which affects the properties of the material. Large colored crumb gives the roofing material aesthetics, reflects sunlight better and protects the material from ultraviolet radiation.

- On the seamy side, roofing material is sprinkled with sand, talcum powder, slate chips. This dressing prevents the layers from sticking together during the curling of the web.

The product labeling indicates the characteristics and density of each layer. This allows you to immediately select the desired option.

Features of use

The scope of application of roofing material depends on its composition and characteristics. There are 2 types of flooring:

- top roofing - a more rigid and durable option, with stone dressing on one or both sides;

- the lower lining is soft, often without powder at all.

Roofing roofing felt is used in this capacity. Especially in demand is the material for covering flat roofs and slopes with a slight angle of inclination in garages and sheds. Of the many roofing decks, only roofing felt has a sufficient degree of water resistance. The budget material is used to overlap outbuildings and gazebos of any type.

Due to its elasticity and softness, the lining is often used for waterproofing structures in order to prevent the ascent of moisture through the brick from the ground into the walls of the building.

The type of sprinkling helps to determine the purpose of roofing material.

- Coarse - Apply to one side only. Thanks to her, the material acquires additional rigidity and strength. It is intended for flooring the roof of a wooden or brick house.

- If only one side is sprinkled with stone chips, and a dust-like layer is applied to the second, such material is laid only on top of the roof. Its task is not to leak water.

- The mica crumb flake is applied on one or both sides. Mica particles are small enough, such a material retains flexibility, but at the same time it is resistant to ultraviolet radiation. It is used as the top layer of multi-layer decking.

- Lining roofing material is most often sprinkled with quartz sand. The material remains flexible, which is important when arranging complex waterproofing.

- Chalk and talcum powder are also applied on both sides of the canvas. This option is allowed to be taken only for waterproofing or as a backing layer, for example, under the crate.

On the seaside or in very rainy areas, the materials that are most resistant to water and salt are chosen. From roofing materials it is better to take a cloth based on fiberglass, since it is insensitive to high humidity and does not contribute to mold.

The difference between roofing and glassine from roofing material

The lower layer of the canvas is sprinkled with fine-grained mineral sprinkling, the upper layer - with sandy or hard coarse-grained. Roofing paper is very soft and cheap, it is convenient to use it for wrapping structures, like a crate.

Roofing paper is used as a lower roofing material, rough flooring, as a temporary roof and for waterproofing. Its disadvantage is a short service life, it is only 1 year.

Glassine is a type of roofing material intended only for waterproofing, as it belongs to non-covering materials. Glassine is used as a lining in multi-layer roofing structures, if bitumen shaped sheets or asbestos-cement are laid on top. It is allowed to put glassine as a top layer, if bitumen mastic can be applied on top and gravel can be embedded into the layer, thus creating a protective stone cover.

High-quality glassine has no cavities, bumps, bulges, retains flexibility and absorbs water by no more than 20%.

Types of material, dimensions and thickness

Armored

Glass roofing material - a canvas based on fiberglass. The material is not susceptible to mold and rot, which ensures an exceptionally high durability of the coating - up to 20 years. Spreading is possible on 1 or 2 sides.

Distinguish glass roofing material by purpose and type of sprinkling:

- S-RK - a variant with coarse-grained mineral chips, used as a topcoat;

- S-RF - a cloth with a scaly dressing, also suitable for the top layer, but more flexible;

- S-RM - option with dust-like dusting. Serves as waterproofing.

Glass roofing material is much more expensive, so it is rarely used to cover the outbuildings.

Euroruberoid

The deposited material. The basis is fiberglass or fiberglass, which increases the strength and density of the canvas. The base is impregnated with purified bitumen enriched with polymer additives. The bottom sprinkling is usually sand, the top - mineral chips.

The main feature of the euroruberoid is the laying technology. When decking, there is no need to coat a large roof surface with mastic or glue. The roll is unrolled by heating each piece with a gas burner. The bottom bitumen layer melts. The canvas is rolled out on the surface, the next fragment is pressed and heated. Bitumen polymerizes, firmly bonding with the base material. The technology is easy to do with your own hands.

The melting temperature of roofing material is low, it is enough to warm up the canvas to 180–240 ° С.

Liquid

This option has no hard basis. It consists of bitumen with special plasticizing additives. This mixture is applied to the roofs with a regular brush or sprayed. When solidified, the liquid roofing material forms a dense waterproof film without seams and overlaps.Modifying components are added to the mixture, providing increased frost resistance, higher resistance to ultraviolet light.

Liquid roofing felt is the best option for waterproofing and covering a flat concrete roof.

Uniflex

A type of roofing material, the bituminous impregnation of which includes artificial rubber. The additive gives the material frost resistance and a higher ability to retain heat. Uniflex is produced both for lining and waterproofing, and for covering the roof.

The base of Uniflex can be polyester, roofing cardboard, fiberglass. Cloth without dressing is used as waterproofing, with dressing - for the roof.

Reinforced

Another type of roofing material with improved characteristics. Its basis is fiberglass, specially reinforced with mesh. The material is thicker and more durable. Since the sheet is reinforced in length and thickness, it can withstand high loads.

On the hardness scale, the material index reaches 5 points. Refers to weldable, it is quite simple to mount it. The top dressing is granite, very hard.

1 layer of reinforced roofing material replaces 3-4 layers of the classic one.

Self-adhesive roofing material

An adhesive composition is applied to the seamy side of the canvas. During installation, the material can be left unheated. The protective film is removed from it, releasing a layer of glue, and immediately rolled out along the base of the roof.

The lining material has an adhesive layer on both sides. The finishing one is covered with glue only on one side. The top layer is formed by stone chips, often colored.

Marking and its decoding

- the first letter "P" is the type of material;

- the second indicates the use of roofing material - roofing or lining material;

- the third indicates the type of dressing;

- The 4 digit indicates the density of the base.

Using this data, it is easy to decipher the code on the package.

- RKP 350 - roofing material with dust-like dusting. Designed for laying inside the roofing cake, it is used for any roof slope.

- RKK 350 is a roofing sheet of the same density, but used as the top layer of the flooring. The top of the canvas is sprinkled with stone chips and is insensitive to ultraviolet light.

- RKK 400 - the properties of this roofing material and the purpose are similar to RKK 350. However, the base is a material of higher density. It is used when the roof is exposed to high wind loads.

- RPP 300 - the raw material for lining roofing felt is roofing cardboard of lower density. Dust-like dusting. The canvas is flexible and soft, used for waterproofing.

- RPP 200 is an even softer material. It is often used as a lining layer.

Additional letters and numbers may appear in the markings. For example, the last letter "A" means that the cardboard in the base material has an absorbency of 145%.