Ordinary screws are poorly fixed on a thin metal sheet, which makes it impossible to install the corrugated board on the structure. The absence of a wide washer causes rapid wear of the base in the place of the fastener. In view of this, it is necessary to use special self-tapping screws for profiled metal sheets.

Requirements for fasteners for corrugated board

Installation of screws for corrugated board is carried out without hole preparation. Therefore, the production of self-tapping screws is being promoted a number of requirements:

- Tip presence, penetrating easily into the metal.

- Manufacturing material - galvanized steel, which is able to withstand prolonged contact with water without oxidation.

- Availability latex sealant, elastic or neoprene to seal the hole.

- Fastener dimensions 2 mm more of the lathing timber and the roofing metal sheet are selected.

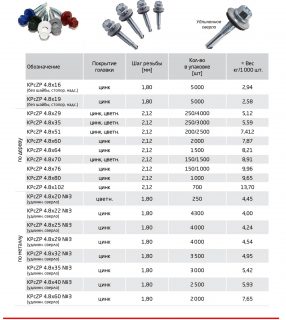

- Length of elements is 19-250 mm with a diameter of 4.8-6.3 mm.

- Fixing screws ridge profile - 4.8x60 mm.

- Manufacturers paint the heads self-tapping screws in the color of the roofing to visually hide the attachment points.

Galvanized steel fasteners belong to the premium group. Consumption of screws per 1 m² of sheet is 9-10 pieces. For end mounting, you will need ~ 2 times more self-tapping screws.

Types of self-tapping screws for profiled sheet

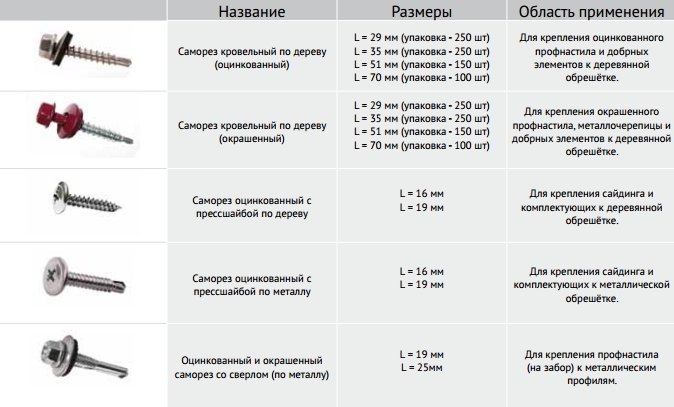

Different types of metal screws are used to lay the profiled sheet. The type of self-tapping screw depends on the installation site and design features. Roofing - designed for installation of roof coverings. The fasteners are equipped with an anti-corrosion and decorative coating. Sealing is ensured by a detachable synthetic washer.

Screws with press washer used for fastening flooring to fences and facades of houses. They are mainly covered with anti-corrosion compounds, less often with decorative ones. The head shape can be hexagonal, semicircular or countersunk. When fixing, rubberized gaskets are additionally used.

Technical specifications

Number of self-tapping screws for corrugated board depends on the purpose of installation. Metal sheets are used for roofing, façade, fence and finished structures. The number and type of screw will differ depending on the frame.

Characteristics

General characteristics of hardware:

- size for metal - 13-150 mm, ѳ 4.2-6.3 mm;

- wood length - 29-80 mm, ѳ 3.5-4.8 mm;

- roof type - ѳ 4.8 mm;

- weight - 4-50 kg / 1000 pcs.;

- tensile strength 100-150 kg.

Features of the self-tapping screws for corrugated board:

- Drill size - a point with 2 feathers, used for fastening metal up to 2 mm. In other cases, the parameter is 3.35-4.2 mm.

- Types of heads - semicircular, cylindrical, spherical. Equipped with splines in the form of stars, crosses or straight lines.

- Thread - thickness up to 0.5 mm, which is taken into account in the thread pitch for fasteners for metal. For wooden surfaces, the parameter increases.

- steel grade corresponds to GOST 1435-99.For wood screws, U7 or U7A steel is used, for metal - U12 or U13.

For your information: zinc coating helps to protect the place of fasteners from metal corrosion, so fasteners should not be made of cheap non-ferrous alloy. This layer prevents the appearance of rust.

Calculation of the number of screws

Number of self-tapping screws for the fence:

- To fix the flooring on the frame fences, you will need 10-15 pieces per sheet 1.1 m wide. On horizontal bars in the cells between the supports, 6 self-tapping screws are used per one support.

- Extreme elements are installed on the attachment points of two sheets - one panel requires from 8 to 12 pcs.

Count number of professional sheets is carried out according to the formula: divide the length of the fence by the width of the material without overlap. Based on the standard sheet size of 118 cm, the length will be 110 cm.Number of support postsdepends on the height of the fence.

Attachment procedure

Manufacturers of self-tapping screws for fastening a profiled sheet note that hardware is capable of independently flashing material up to 2 mm thick. If the corrugated board is 4-5 mm, before work it is necessary to make markings and drill holes in advance.

List of instruments

Corrugated board it is recommended to purchase equal length up to 12 mm... Material thickness and wave height depend on design features. The number of sheets is rounded up, since the stacking is carried out overlap horizontally by 8 cm and vertically by 20 cm.

The selection of self-tapping screws for metal for corrugated board depends on the material of the crate - wood or metal. To carry out the work you will need:

- screwdriver with an attachment for hexagonal heads;

- wrench;

- roulette;

- pencil;

- instruments for working with metal;

- building level;

- cord.

The use of a grinder is relevant for budget material. After installing low-quality sheets, all surfaces must be painted.

Stages of work

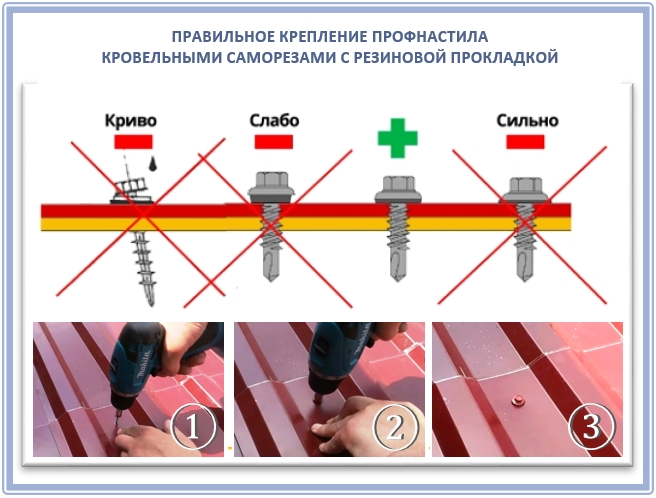

The process of attaching profiled sheets to the frame:

- The alignment of the bottom edge of the material is carried out by pulling the cord.

- Start fastening from the edge of the bottom sheet on either side of the structure.

- If the coverage area is large, use the overlap method with the obligatory fixation of the overlapping area of the plates. Additionally, install self-tapping screws along the edges, and then align the sheets.

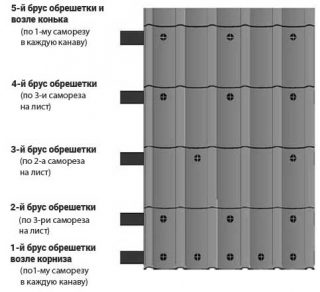

- The subsequent introduction of hardware is carried out at each lower point of the wave along the entire length and through the wave vertically. After completing this stage, screw the screws in the rest of the sections with a screwdriver. Insert fasteners strictly perpendicular to the surface.

- Proceed to the installation of the next block, expanding it with an overlap of 20-30 cm with the first one. If the size of the crate is not enough, trim the sheets. Fix the junction with metal screws, introducing into each wave.

- Treat the junction areas with a sealant.

- Adhere to an attachment pitch of 30 cm in relation to the additional elements.

If profiled sheets are used as roofing material, it is necessary to choose hardware for the roof.

Nuances of fastening screws

Application of profiled sheets for roof covering requires giving the material waterproofing properties and resistance to wind loads. For this are used special fasteners for corrugated board and a small step of the frame. The ridge is fixed with long screws.

If the material is selected for facade cladding as insulation, the step of the lathing depends on the characteristics of the heat insulator. Often this parameter ranges from 0.5 to 1 meter. In most cases, the wall anchoring method is used to secure the sheets. It is allowed to use self-tapping screws with a press washer equipped with a rubberized gasket.

When installing a profiled sheet fence, wind loads on the structure must be taken into account. To ensure stability, the material is fixed on logs in each wave.

To give the fence a decorative look, it is recommended to use colored self-tapping screws. For example, if the sheets are oak-like, brown or gold screws will do. In this case, for installation, it is allowed to use hardware with a press washer and gasket.