Siding is a common material for facade cladding. Often, the base walls of the house look unsightly or need protection from the sun, water, frost. These tasks are solved by the cladding.

What is siding

Buildings are built from a variety of materials - brick, concrete, wood, stone. Each of them has its own advantages and disadvantages, and they are not always combined to the extent that the user needs. For example, concrete is strong, vapor-permeable and durable, but cold, ugly and unstable to chemically aggressive substances. The tree, on the contrary, is beautiful and retains warmth, but at the same time it easily lends itself to mold and decay, and shrinks.

The combination of wall material and cladding can resolve this contradiction. It is enough to choose a skin that has the required properties.

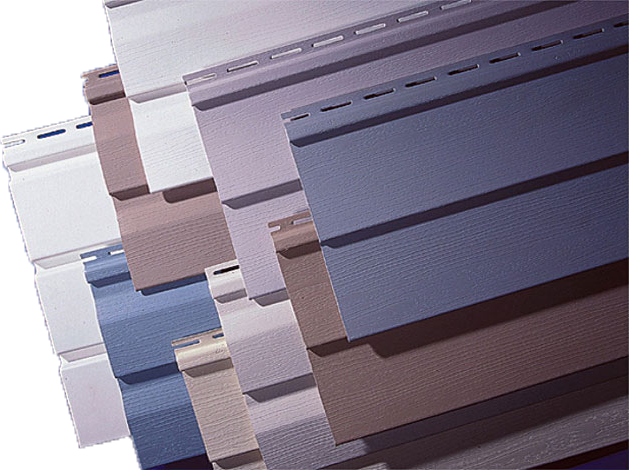

A-priory siding - material for wall cladding and basement... Available as lamellae - long pieces of board-like shape, and panels... The latter are larger and usually reproduce masonry or brickwork.

Siding is made andfrom a wide variety of materials: fiber cement, metals, plastics, modified materials. This allows you to choose from a variety of siding options for any building.

Siding types

Types of outdoor siding in the first place classified by material of manufacture... The form factor they have may be different, but the composition largely determines the characteristics.

Metallic (steel)

For siding they take steel, aluminum, copper... The latter option is used extremely rarely, as it is very expensive.

Steel siding is made in the form of lamellas 12-30 cm wide and up to 6 m long... The base is black steel, which is coated with a layer of zinc. This metal protects steel from corrosion. Another protection mechanism is a layer of polymer paint. The latter also determines the color and texture of the product.

It is forbidden to put steel siding on the wall, even if the surface is perfectly flat. A ventilated facade is being installed.

Most often, the steel finish imitates the shape and structure of a wooden bar, but there are other, unusual models.

Aluminum

Aluminum is a metal that does not corrode... In air, it instantly becomes covered with a thin layer of oxide, which prevents moisture and oxygen from contacting with the metal. There is no need to protect aluminum. Therefore, lamellas from it often retain their inherent color and shine.

Vinyl

Comprises polyvinyl chloride... During manufacture, a substance is added to the initial mixture that gives the finished product certain properties. Siding is being produced by extrusion method.

Vinyl slats two-layer... The inner layer provides strength and rigidity due to the addition of calcium carbonate to the mixture. The outdoor unit is resistant to moisture and sun.

There are also claims to the appearance of vinyl. The building material is affordable, but due to its very high uniformity looks too cheap.

Acrylic

Acrylic resins are used for the outer siding layer. Compared to vinyl sheathing, acrylic is more practical.

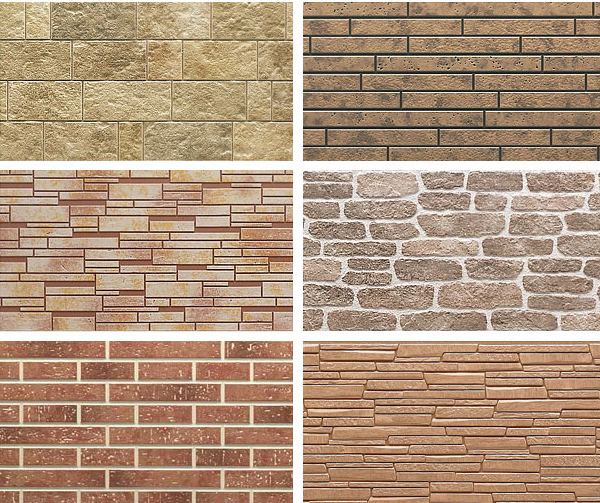

Acrylic siding is produced in the form of panels and reproduces brick or masonry. The decorative ability of the material is better, therefore the finish looks natural.

Wood fiber

The material is obtained by pressing wood shavings followed by processing with polymer resins... The cladding combines the advantages of plastic and wood and is devoid of the disadvantages of the latter.

Wood fiber siding is produced in the form of lamellas, which can have a different profile, imitating a log, a wooden bar.

Cement

Fiber cement panels are made from cement, sand and some synthetic or natural fibers... This material provides maximum protection for the facade.

Fiber cement siding is preferred by those for whom the durability of the finish is a priority.

Ceramic

Ceramic siding is made on the basis of clay; in terms of properties and manufacturing method, it is similar to fiber cement, but has some additional qualities. The material is fired at the end of the production cycle, which makes it more expensive and of better quality.

Siding classification by purpose

The siding material to some extent determines and appointment.

- Stenovoi - designed for facade cladding from base / plinth to roof. The casing is not in contact with the ground. Wall slats and panels are varied and designed for different wind and rain loads.

- Basement - such a cladding is mounted close to the ground, and sometimes comes into contact with it. It is made of materials that are resistant to moisture: metal lamellas, acrylic. Fiber cement and chipboard materials are not used for plinth plating.

- Soffit - material intended for filing cornices and overhangs. As a rule, the lamellas are perforated, since it is important to provide ventilation in this area. For the manufacture, materials are taken that are poorly resistant to the action of water and ultraviolet radiation, since this area does not get exposed to rain or the sun.

Major manufacturing companies

- Tekos is part of an international holding. Offers various types of vinyl and acrylic cladding.

- Grand line - produces plastic cladding, both lamellas and facade panels, as well as metal siding.

- FOUNDRY is an American company. Offers 6 collections of facade panels. Its distinctive feature is the originality of the design.

- Mitten is a Canadian concern that produces only vinyl siding. However, it is designed for a harsh climate, therefore it is distinguished by outstanding resistance to frost and moisture.

- Kmew is a Japanese fiber cement panel manufacturer. Produces 4 collections with coatings for air purification, self-cleaning, UV protection.

Chinese and Turkish manufacturers offer vinyl and metal siding at low prices... However, when purchasing the material need to be carefully checked.

Comparison with other facade materials

Siding in construction is popular due to its unique combination of qualities. Sheathing is preferred over other finishes.

- A simple way to decorate the facade - plaster... The material is affordable, very light, and quite varied. The plaster conducts steam, so the risk of condensation is minimal. But at the same time, the finish is very short-lived and must be renewed at least once every 3-5 years. Siding, even a cheap one, is much more durable, and the problem of removing steam from the premises to the outside is solved by installing it on a frame.

- Sheathing clapboard is also very popular. The tree retains heat, weighs little, and allows steam to pass through. However, it is prone to rotting and damage by fungi and insects. Such a finish needs to be looked after.Wood fiber siding is insensitive to moisture and frost and lasts longer.

- Cladding ceramic bricks and clinker - an expensive procedure. In terms of strength, little can be compared with it. However, this method is extremely laborious, time consuming and expensive. Siding mimics brickwork and is much cheaper.