Siding belongs to the category of popular materials for interior and exterior cladding. They use imitation of stone, leather, brickwork, as well as log siding for outdoor decoration. The texture conveys different types of wood, and the overall layer resembles walls made of blocks with a rounded surface.

Description of siding, advantages and disadvantages

The material is used for wall cladding, while they play a decorative role and additionally protect vertical structures from negative factors. A variety of panels with imitation of logs looks like natural wood externally. The drawing and texture are rendered so realistically that the structure seems to be folded from wooden lumber.

Advantages of siding:

- used to decorate houses from any building material;

- during the service life, the initial properties hardly change;

- the coating on the surface makes it resistant to ultraviolet light and fading;

- no special care and repair of the facing layer is required, it is easy to wash with the use of conventional detergents;

- during installation, it is possible to stick insulation;

- installation of all types takes place according to the scheme of a hinged facade on a frame, therefore it does not require special experience and knowledge, it can be done by hand.

The cladding hides small irregularities in the facade, so a careful leveling of the surface is not required. This property of the lathing saves money on wall plastering. The type of natural wood is most in demand for facade cladding.

Types and characteristics of different types of imitation log siding

Modern siding panels are made from various materials. For the choice of siding for the exterior of a house under a log, the purpose of using the cladding is taken into account. For decorating outbuildings, sheds, they take inexpensive types, and for a residential building they use better quality and more expensive ones, with a long service life.

For finishing, they produce varieties of siding with imitation of wood materials:

- metal;

- acrylic;

- wood;

- vinyl;

- fiber cement.

All types differ in different costs depending on the qualities and materials. Vinyl, fiber cement and wood materials are considered inexpensive, metal is more expensive. Acrylic siding has the highest value due to the inclusion of modified polymers.

All varieties are placed on a frame made of wooden slats or galvanized elements, installation is carried out from bottom to top, or placed from left to right with vertical strips. For siding under a log house, panels are rarely placed vertically.

Metal siding

There are steel strips with different coatings:

- acrylate;

- polyester;

- plastisol;

- polydifluorionad;

- pural.

Films are applied with a thickness of 25-200 microns. On thick layers (plastisol), in addition to the pattern, embossing is done, which imitates the convex wood fibers. The reverse side of the panel is covered with a protective varnish without a pattern.The finish does not emit toxins when heated, does not fade over time.

Metal siding does not absorb or conduct water and is easy to maintain. On the surface inside and outside there are no conditions for the reproduction of microbes and fungi. The flammability of the material is zero. The disadvantages of steel strips include the fact that the material has a significant weight, makes the walls heavier.

Acrylic panels

The final finishing consists in applying a high quality wood-patterned paint protection to the surface. The material allows you to structure the plane in relief to increase the reality of the perception of the micro-texture of the tree.

Useful qualities of imitation log acrylic siding:

- sufficient strength for use in outdoor decoration;

- trapping additives in the composition weaken the effect of ultraviolet radiation;

- does not conduct heat, therefore protects walls from cold;

- inert to the action of atmospheric chemistry (acids, alkalis, oils);

- does not rot, does not corrode;

- does not get spoiled by bugs, parasites, rot and mold.

The disadvantage is the high cost of the material.

Wood siding

Modern processed wood siding has the following qualities:

- moisture absorption is negligible due to wet heat treatment during manufacture;

- in case of fire, they will ignite only at high temperatures;

- the tree is dried to a moisture content of 15 - 18%;

- for the manufacture use solid larch, teak, birch, oak;

- impregnation with an antiseptic is done by impregnation (under pressure).

Log siding is commercially available with tongue-and-groove, quarter, overlap, butt joint.

PVC sheathing

Material advantages:

- lightweight PVC creates almost no load on the facade;

- easy to assemble, machined with tools;

- serves for a long time (10 - 15 years);

- completely resistant to water, does not degrade in humid climates;

- retains its initial characteristics at temperatures in the range - 50 ° - + 60 ° С;

- easy to clean and clean from dirt;

- microbes and mold do not live on the surface.

Vinyl panels are not placed on the sunny side of the house, since the color fades over time and becomes dull. If the plastic cracks from the impact, the repair consists in replacing the strip, for which you need to disassemble the subsequent boards.

Fiber cement material for wood

The composition contains cement, fibers serve as a filler, to improve quality, they include minerals and dyes. The materials are mixed under the action of high temperature and pressure. Wall cladding boards represent a modern type of facade cladding.

Slab characteristics:

- the thickness of the strips is 8 - 12 mm, the width is 19 - 20 mm, the weight of one panel is 11.2 - 16 kg;

- absorb up to 20% moisture in the mass;

- withstand 15 cycles of freezing and thawing without deformation;

- do not burn;

- the service life is planned at the level of 50 years, while the color remains for about 15 years, then you need to paint again;

- do not rot, do not deteriorate from corrosion, environmentally friendly;

- can be combined with other types of finishes.

Cellulose fibers give flexibility, elasticity. There is a type of fiber cement with the inclusion of wood fibers, but this is not taken for the facade, since the material absorbs moisture. The disadvantage of fiber cement is that, due to the impressive weight, the cladding is planned at the design stage. Otherwise, you need to strengthen the base of the house.

Siding house cladding algorithm

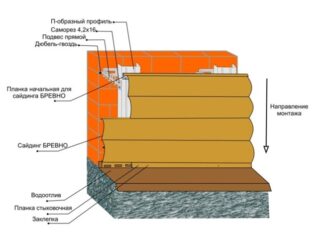

First, the surface of the facade is prepared: large irregularities, weak layers are knocked down, then cracks are sewn and primed. For siding, it is better to take a galvanized profile from the drywall fixing system. For the racks, the elements CD - 60 are used, for the lower and upper strapping, the UD - 25 profile is mounted under the starting and finishing strips. The crate is fixed to the wall on ES brackets with a length of 120 or 200 mm. At the same time, insulation and waterproofing are installed.

Installation procedure for siding panels:

- a starting bar is installed, the lower edge of the first board is brought into it;

- pull up to the stop, snap into place, fix the top of the strip to the crate with self-tapping screws;

- they begin to fasten from the center of the board, gradually moving to the edges;

- self-tapping screws are placed in the center of the oval slot, they are not completely tightened by 4 - 5 mm so that the siding expands when the temperature changes.

The following boards are also tightened until they snap into place, fixed with self-tapping screws. Before the installation of the last panel, a finishing strip is installed, into which the strip is inserted as a whole or cut off. A J-profile is placed around the windows and doors before the start of the set of the plane, to decorate the perimeter of the openings. Internal and external corners are decorated with overhead strips.

Beautiful examples of cladding

Siding walls under a log looks good in combination with other materials. For example, the pedestal of a building is decorated with a similar type of siding with imitation of stone or brickwork. As a result, the building looks solid, since the plinth should always look heavier than the facade.

If you place the siding boards vertically, you get a wall like a palisade, this technique is sometimes used by exterior designers to enhance the uniqueness of the structure, to give individuality.

Sheathing under a log always looks good in combination with red brick, rubble masonry walls. If the facade is made with such materials, only individual parts are faced with log siding. On protruding columns, bay windows, pediments, accompanying material is left.