For cladding a house, you can independently calculate the number of panels, siding components. There is no single standard for strip dimensions, so manufacturers themselves determine the characteristics of their products. The buyer needs to know the dimensions of siding for outdoor decoration in order to find the amount of material, calculate the cost. The length and width will help determine the location of the boards, the amount of waste, the weight of the cladding outside the house.

- The main parameters of siding for outdoor decoration

- Length and width

- Thickness and weight

- Siding types and their standard sizes

- Vinyl siding

- Wood siding

- Aluminum siding

- Galvanized metal siding

- Fiber cement siding

- Facade zinc panels

- Ceramic siding

- Sizes of basement siding panels

- Calculating the amount of siding for the exterior cladding of the house

The main parameters of siding for outdoor decoration

The calculation of the number of strips of any type of siding depends on its dimensions. Specified parameters, for example, the length of siding for outdoor decoration, its width are given in the catalogs of manufacturers. Such lists can be viewed in every hardware store, where price lists of manufacturers whose products can be ordered are collected.

The material parameters are used to calculate:

- number of panels;

- molding of additional strips;

- the number of component parts, hardware;

- lathing options.

If you take averaged data for the calculation, you can buy excess material or it will not be enough. In the first case, you need to return the finishing panels, and in the second, order additionally, which will increase transportation costs and extend the finishing time.

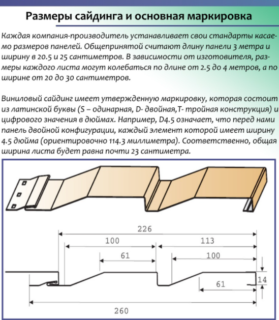

Length and width

Such a perforated part is completely hidden when the next panel is installed, so its width is not taken into account when calculating.

The standard for the profile in length is 3660 mm, this size is available for all manufacturers. Equally popular is the length of 3050 mm, which is suitable for external cladding of small buildings. The user can order the length of the siding panels according to the individual size, based on their own finishing option.

Thickness and weight

These two parameters are often directly proportional. As the thickness of the siding increases, the weight of the panel increases.

The procedure for calculating the total weight of the facing:

- determine the weight of one panel, for this, the width (total) is multiplied by the length and weight of the square, or the finished value is taken from the manufacturer's catalog;

- the result is multiplied by the number of stripes;

- to the total add the weight of the corners, starting, finishing, near the window slats, lathing, insulation.

If a significant weighting of the finish is obtained, measures are taken to strengthen the foundation, otherwise the wall will sag under the influence of the additional weight. Fiber cement, metal, zinc siding significantly add bulk to the wall.

Siding types and their standard sizes

For cladding, siding is used from different materials, the properties of which affect the characteristics and dimensional indicators of products.

Modern types of finishing panels are made from materials:

- wood, natural and pressed;

- aluminum;

- fibrosiding;

- galvanized steel;

- zinc;

- ceramics.

There are wall and basement types of slabs.Before installing the boards, a starting and finishing strip is installed on the wall, connecting and J-strips are attached around the openings. After the installation of the siding layer, the corners of the building are decorated with external and internal overlays. In the process of cladding, strips for platbands, hinged profiles are used, they are completed with near-window elements and soffits.

Vinyl siding

- sheet thickness varies from 0.6 to 1.3 mm;

- useful height - 200 - 255 mm;

- total sheet height - 220 - 275 mm;

- the area of the strips is 0.65 - 0.85 m²;

- length - 3000 - 3800 mm;

- one slab weighs 1.5 - 2.0 kg.

Too thin plastic products can crack in winter in frost. The material is assessed not only by its thickness, but also by the composition of the raw material, its chemical parameters; the number of modifiers (additives) matters. Vinyl siding imitates logs, wood planks, brick, stone, and other materials.

Wood siding

Users purchase wood siding because of the familiar natural look of a residential building, finished with this material. The surface of each sheet has its own configuration, unlike other models.

Dimensions of wood siding for outdoor use:

- the length and width of the strips - 3500 - 5500 mm and 140 - 220 mm, respectively;

- siding thickness - 10 - 23 mm;

- useful width is 135 - 210 mm;

- the area of the board is 0.5 - 0.9 m2.

Correspondence of the dimensional parameters can be violated if the wrong technology was used in the manufacture, for example, drying. Wet parts of the required size can dry out, dry ones become saturated with moisture, so the initial dimensions will change.

Aluminum siding

Dimensions of aluminum strips:

- the length of the panel is up to 6000 mm;

- siding strip height - 225 and 300 mm;

- thickness 0.5 - 1.2 mm;

- the slab weighs 2.5 - 3.6 kg.

Aluminum siding does not corrode, it is a ready-made material that does not need to be pre-processed before being installed on the walls of the building.

Galvanized metal siding

The most common material among metal profiles. It is based on a metal sheet, which is covered with a zinc oxide film by the electrolyte method. The coating protects the surface from rust and deterioration.

Dimensions of siding with a polymer layer:

- length varies from 2000 to 6000 mm;

- the thickness is different - from 0.45 to 1.1 mm;

- width of metal siding - 100 - 550 mm;

- strip weight 6 - 12 kg.

Pure galvanized siding is rarely used, more often a painted version with a polymer coating is used. The film decorates the material, imitates natural materials, stone and brickwork. Thanks to the additional layer, the resistance to corrosion and moisture is increased.

Fiber cement siding

The material contains Portland cement, mineral or asbestos fibers, water. In addition, minerals are introduced to stabilize the properties. Panels differ in high weight and thickness, so their weight is laid at the design stage of the house in order to take into account when building the foundation.

Cement siding panels have dimensions:

- length - 3000 and 3500 mm, strip height - 186, 190, 200 mm;

- the thickness of the slabs is 8 - 15 mm;

- one item weighs 12 - 24 kg.

Cement siding has a long service life - about 45 - 50 years. Modern material is produced with the addition of coloring pigments in the mass, so the panels practically do not fade for 12-15 years, then the walls need to be painted.

Facade zinc panels

The cost of products is high, because of this, their use is limited.

The fittings are used similar to those used for vinyl siding, but such products differ in configuration:

- Facade paintings. Roll width 500 - 600 mm, material thickness 0.65 - 0.8 mm;

- Wall horizontal panels. Thickness - 1 mm, width 200 - 300 mm, length of strips 500 - 6000 mm;

- Facade shtulpovye slabs. Thickness - 0.7 mm, element size 3000 mm in length, 200 mm in width.

- Outdoor modules in the form of rectangles and squares with dimensions ranging from 450 x 450 to 600 x 2400 mm.

- Wall profile with a wavy surface. Product thickness 0.8 - 1.0 mm, length - 6000 mm, profile width - 720 and 836 mm.

The material looks perfect on the facade, is durable and durable. Zinc panels are combined with other types of wall finishes.

Ceramic siding

They are produced on the basis of a combination of clay, cement with natural mineral fillers, which are pressed under pressure in a high-temperature mode during the manufacturing process. The environmentally friendly material does not release hazardous ingredients into the air when exposed to the sun. The surface is designed to match the texture of brick, stone, wood, leather.

Panels are available in dimensions:

- length - 3000 - 3600 mm;

- width - 210 - 650 mm;

- thickness - from 10 to 18 mm;

- the weight of one square is 18 - 26 kg.

The severity of the slabs limits their use only to buildings under construction, where the mass of the finishing layer is laid down at the stage of drawing up the project. For such a profile, reinforced crate systems are used, the frame must withstand a lot of weight.

Sizes of basement siding panels

The division of siding into wall and basement views is purely conditional. For the pedestal of the house, panels from all types of material are used, but of such thickness that they withstand negative influences. In addition, the siding should not absorb moisture, since the basement is located next to the ground, soil moisture, snow drifts and rain act on it. Foamed vinyl is not used for cladding the lower part of the building due to its porosity.

The siding is placed on a frame, so there is a possibility of insulating the basement of the building, which is important for the basement.

For the lathing, a metal profile is used to protect the system from deformation due to moisture. The casing should not react to acid precipitation, alkali, collapse at temperature extremes, should withstand blows from feet and other objects.

Calculating the amount of siding for the exterior cladding of the house

Measure the length, width and height of each wall separately, find the area by multiplying these indicators. The resulting values are added to determine the total quadrature. The total is divided by the usable area of one siding strip. The indicator can be calculated independently or contact the supplier. The resulting number of strips is multiplied by 1.1 to account for the cut to size.

In addition, the length of the inner and protruding corners on the house is considered, and corner strips are ordered from them. The length of the start and finish strip is taken along the perimeter of the house at the bottom and top. The J-plank is considered along the perimeter of the openings, the same is done with the platbands and the framing of the slopes. If the panels are connected with a docking bar, its length is taken at the installation site.