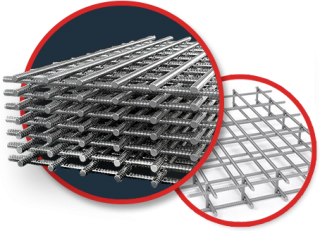

Reinforcing mesh is a structure made of rods connected or welded to each other, laid perpendicular to each other. Fittings are manufactured in accordance with GOST 23279-85. The mesh is used in a wide variety of construction work: from reinforcing concrete screed to reinforcing bridges.

Features and varieties of reinforcing meshes

For the manufacture of fittings use wire, as well as rods of cold drawn or hot rolled steel. By the size of the original elements and the location of the working reinforcement of the product classified as follows:

- heavy - made of rods with a diameter of 12 mm, used in the production of reinforced concrete structures;

- lungs - are made of an element with a diameter of 3 to 10 mm.

- heavy with working reinforcement located in the longitudinal direction;

- heavy with fittings in both directions;

- heavy, in which the cross-section of the transverse rods is greater than the value of the longitudinal ones;

- lightweight with cross members over the entire width of the mesh;

- heavy, where the transverse rods are displaced.

Cell shape can also be different:

- square - option with reinforcement placement in both directions;

- rectangular;

- different shapes - for example, for decorative fences.

Issued several dozen standard sizes... For example, in heavy models, models with cells of 100, 150 and 200 mm are most often found. In fine-mesh light nets, the dimensions are much smaller: 5 mm, 10 mm, 20 mm.

Black steel not too resistant to corrosion. In certain cases, this does not matter, in others it is important to protect the metal from rust. Release 3 options:

- polymer coated fittings;

- galvanized - durable and does not need periodic renewal of the top layer;

- without protective coating.

In addition to metal fittings, they produce composite. This option is used to reinforce the finish, like plaster.

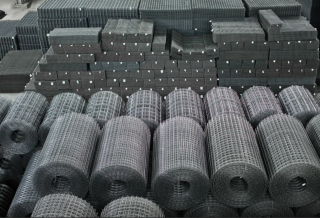

Welded reinforcing mesh is produced in the form of rolls and cards. The first option is flexible and lightweight. A flat card is made of elements with a diameter of more than 30 mm, it is no longer possible to fold it.

GOST requirements

The technical characteristics of the reinforcement mesh are regulated by GOST 23279-85... The standard dictates the exact dimensions of the cells, the diameter of the rods used, the distance between the elements, the length of the outlets and possible deviations from the norm. GOST describes the entire product range.

According to the standards, all types of fittings are divided into 5 types:

- reinforcing mesh C1 - heavy, with a diameter of rods from 12 to 40 mm and a distance between longitudinal elements - 20 cm, transverse - 60 cm;

- C2 - heavy with square cells of 20 cm and a diameter of 12 to 5 mm;

- C3 - also has square cells, but is made of rods 6–16 mm thick;

- C4 - refers to light, made from a rod with a diameter of 3-10 mm;

- C5 - is made of even thinner reinforcement - with a section of 3-5 mm.

The dimensions of the cells of a light product range from 10 * 7.5 cm to 50 * 40 cm.

- blanks for heavy nets only a bar made of reinforcing steel of class A500SB A600S, A400 can serve;

- light mesh made of B500C class reinforcing steel;

- connect rods only spot welding is allowed, but the welding mode and the frequency of welding are determined by the current TOR.

GOST also regulates the rules for product acceptance.Selected samples are checked for the dimensions of the outlet, the shape of the rods and the value of the reinforcement settlement.

Scope of application

The fittings are used in a wide variety of construction work. For each, products of the appropriate type are selected.

Rolled mesh used for the following works:

- pouring a concrete screed;

- construction of bridges;

- construction of fences - the chain-link also belongs to the reinforcement;

- construction of wells and tunnels.

Option in cards it is more durable. Heavy nets are used for the following purposes:

- strengthening of structures - roads, bridges, foundations, blind area;

- reinforcement of floors;

- separation of bulk materials of various kinds;

- strengthening of masonry - brick, gas block, cinder block;

- sealing pipes;

- almost all finishing and renovation work.

Conventionally, the purpose of the product depends on the thickness of the reinforcing bar and the size of the cell. In fact, the same road mesh is taken for the construction of corrals and fences for large animals, during repair work inside the house.

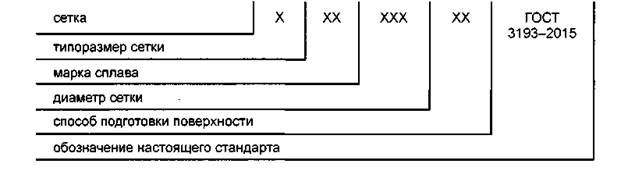

Marking and decoding

Mark the product in the following way:

- X - the first letter indicates the type;

- FROM - indicates that the products are offered in cards, if Ср - in the form of a roll;

- d - the size of the longitudinal bar;

- d1 - diameter of the transverse bar;

- B - product width;

- L - the length of the reinforcement.

Usually, after the dimeters, the class of steel is also indicated. And for a class 3 projection with a step of 40 cm and for a class 4 and 5 mesh, the step size is also given through a dash after the diameter.

Transport and storage

- Cards are bundled into packages... Maximum package weight - 3 tons.

- The package is tied with a wire in at least 4 places. The roll is fastened in 3 places.

- Each roll or bag is attached with 2 tags, which indicate the plant's trademark, product designation, number of nets, total weight of the roll or bag, batch number and production date.

- Each batch of nets is supplied with certificate and other documentation from the manufacturer. The roll lies loosely on the floor. The package should be supported with a wooden support.

- Reinforcement is transported in a horizontal position.

Store products indoors. Rolls can be stacked in 3 tiers, cards - in stacks no more than 2 m high.