Profiled sheet is a popular roofing material. It is easy and convenient to work with it. Shed, gable and hip roofs, fences are made of lightweight and durable panels, they are used as wall cladding. In order for the roof to be reliable and durable, you need to choose the right step for the girders for the profiled sheet. You can't save money here, but you shouldn't put slats too often, so as not to weigh down the entire rafter system and the house as a whole.

Calculation and design of the lathing

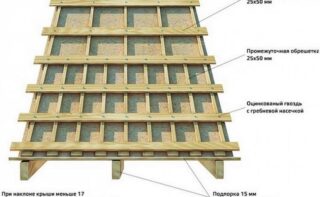

In order to competently and prepared to approach the design issue, you need to choose the optimal one for a particular case lathing device for corrugated board. If this residential building, under it there will be a counter-lattice, insulation, waterproofing and a steam membrane. During construction economic structures usually limited to only a waterproofing film that is attached over the rafters.

The distance between the beams of the sheathing for the corrugated board determines the ability of the roof to withstand wind and snow loads, to remain airtight in strong winds during rain.

When making calculations, you need take into account such factors:

- Climatic conditions. The strength and direction of the prevailing winds, the level of precipitation in the cold season.

- Metal thicknessfrom which the panels are made. The thinner it is, the smaller the spacing between the slats.

- Profile height. Products with high ridges resist mechanical stress much better.

In accordance with GOST, the pitch of the lathing is determined by comparing the steepness of the slope and the height of the corrugation.

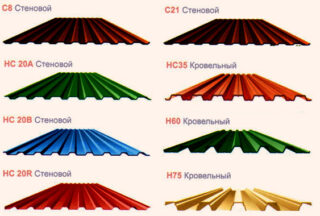

- FROM. Finishing material that is not intended to perform protective functions. The thickness of the steel is 0.4-0.6 mm with a wave height of up to 10 mm.

- NS. Stronger coating with a thickness of 0.6-0.85 mm and a ridge height of up to 44 mm. They are used both for cladding of buildings and in the manufacture of roofs of varying complexity and size.

- N. The toughest and most reliable panels. Used to create roof decking, fences and formwork for floor slabs. Wave height up to 140 mm with a thickness of 0.9-1.2 mm.

Each type of product is accompanied by instructions describing its technical characteristics and conditions of use.